RFID technology boosts the construction of an intelligent production management platform

[ad_1]

At present, most of the manufacturing fields are managed and controlled by focusing on various links of product management, quality management, warehouse management, and on-site personnel management. Data collection is usually carried out by manual collection and manual input, which makes it difficult to realize real-time production data. The update has led to serious production lags, which restricts the further increase of production capacity, causes various data to be inaccurate, reduces the overall productivity of the enterprise, and consumes more manpower. In the past, manufacturing enterprises used one-piece production mode as the main production process. If the process is complicated and there are many production links, it will cause various problems in production. The application of RFID technology will change the production and operation methods of processing and manufacturing enterprises and improve the management level of the production process. Obtain the production data of each link in time, and optimize the control of the production process.

The quick receipt of materials in the production process is an important step. Using mobile smart terminals to collect data through RFID can realize real-time management of production line data, solve the problem of employee production input, improve data accuracy, meet online production scheduling needs, and ultimately improve enterprise production efficiency.

Picker picking

Use the mobile terminal to confirm the identity of the picker;

Use the mobile terminal to read the barcode of the material and confirm the quantity of the material;

Production Process

Use the mobile terminal to record the recipient and the material barcode to confirm the employee card at each station and record the amount of raw materials received by the employee;

After the employee finishes the processing of each semi-finished raw material, and then reads the raw material bar code when starting the second raw material processing;

Start the second raw material processing, and after reading the raw material barcode, reconfirm the employee’s identity information and enter the next process;

Data summary

Through GPRS/3G real-time uploading of data to the back-end server, enterprise management personnel can inquire about employee processing progress and other data at any time.

Data collection: Attach RFID tags to the produced materials or the pallets containing the materials, and record the product specifications, quantity, time, person in charge and other related information on it, instead of traditional manual recording; production management personnel read and write The device can read product information at any time; other relevant personnel can grasp the production status in time and adjust the production schedule according to the situation, as well as control the flow of materials at any time.

Data transmission: Install reading and writing equipment at each collection point. When the materials or pallets with RFID tags pass through the collection point, the reading and writing equipment will automatically obtain the information of the material and transmit it to the background. The manager can accurately know the location of the material through the background. Location.

The main equipment components of the scheme: mainly composed of RFID electronic tags, RFID fixed readers, RFID antennas, RFID handheld devices and RFID cables.

Real-time tracking management: real-time dynamic tracking in the entire production process, when the material passes through the collection point, the reader will send accurate information back to the background to accurately understand the location and status of the online material. Material tracking and contact, material tracing, material cost control, production progress tracking: reduce material backlog.

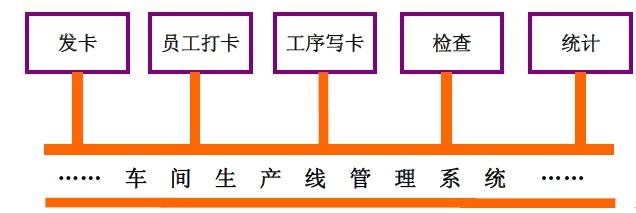

The application of RFID technology in production management quickly processes real-time production data, and manages and monitors all aspects of production. Let the production line material monitoring, product in and out management and incoming material traceability, and the in and out management of the logistics distribution center. RFID automatically collects production data and equipment status data, greatly improving the efficiency of production management and control.

[ad_2]