RFID easily improves the level of fixed asset management

[ad_1]

With the increasing scale of asset management, investment in fixed assets is a prerequisite for the sustainable development of enterprises, and standardized management of fixed assets is related to the survival and development of enterprises. The inventory of fixed assets is related to the company’s grasp of its own assets and equipment status, real-time and accurate understanding of the status of the assets, can effectively control the status of the assets and equipment, and can improve the accurate understanding of the company’s assets. Use RFID to easily improve the level of fixed asset management.

Now, most of the company’s inventory will be handled using barcodes and barcode guns. However, with the passage of time, defects such as the imperfection of barcodes, the small amount of data storage, the short reading interval, and the inability to read in batches gradually appeared, which brought inconvenience to the inventory of fixed assets. These are all RFID fixed assets inventory and tracking. The launch of the system laid the market demand.

Compared with barcodes, RFID can quickly read all tags within the radio frequency range, and the reading interval can be adjusted. It does not require bright light and scans at close intervals. It is significantly better than barcodes in terms of time use and inventory power; more importantly It is now that the global barcode numbers are almost used up. RFID tags can be read and written repeatedly and have a large amount of data storage, which also saves money for enterprises.

At present, most companies have the problem of poor asset management:

1. The assets are large and chaotic, the financial information of stock assets and incremental assets is distorted, asset accounting is seriously untrue, and even the problem of asset loss is caused.

2. The scrapped or damaged fixed assets are not cleaned up in time, and the direction of asset disposal and the person responsible for disposal are nowhere to be found.

3. When there is a flow of asset users, it is impossible to deal with the change of the person responsible for the asset in a timely manner.

4. It is difficult to calculate fixed assets, which consumes a lot of time and manpower.

How to use RFID technology to realize enterprise fixed asset management:

For asset management, the introduction of RFID technology can effectively and conveniently manage the fixed assets of the enterprise, check the arrival of equipment, responsible procurement, in and out of the warehouse and the responsible person, asset use right information update and use history query, and The data of each operation link such as asset allocation, fault maintenance, equipment inventory location, asset calculation reports and financial accounting are automatically and accurately recorded to ensure data accuracy and avoid the loss of fixed assets of the enterprise.

Application advantages:

1. Label management: Each piece of equipment is given a unique label through RFID technology, which is convenient for query and management.

2. Asset secondment management: When the equipment is borrowed and returned, the PDA is scanned to complete the borrowing. When there is a quality problem, you can check the borrower’s record and track the person in charge. Convenient operation and management successfully solved the equipment secondment problem.

3. Asset standard management: Use PDA to scan, you can easily get the equipment number, name, status, specification, model, parameter, instruction manual, etc. At the same time, if there is quality problem, you can apply online in time, and the management staff will receive the information and make it in time. Feedback processing: For equipment that has failed, managers can use feedback to change the status of the equipment in time on the mobile phone or in the background so that users can inquire about maintenance information.

4. Data analysis: According to the big data statistics of equipment management, such as equipment borrowing data, purchase and purchase data, department allocation data, personnel flow data statistics, maintenance data and other information, and according to the management method requirements, various reports can be exported with one click.

5. Accountability: For equipment procurement, procurement time, equipment distribution management, users (including previous and current), maintenance reasons, scrap processing, etc., there are traces to be traced and accurate to every second.

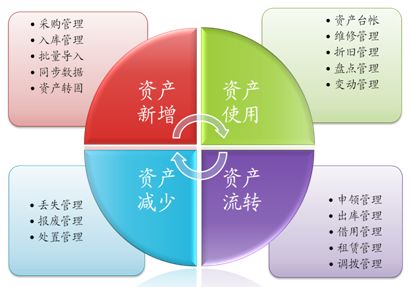

Realize “asset life cycle management” and “asset automatic management”: use RFID technology, radio frequency automatic identification and GSM communication network wireless remote transmission functions, to achieve the full life cycle of assets (new addition, allocation, idle, scrap, maintenance, etc.) ) Intelligent dynamic real-time tracking of the process, centralized monitoring and management, the entire management process does not require any manual intervention. It provides accurate reference data for enterprise investment decision-making and reasonable asset allocation, effectively increases the marginal benefit of investment and increases the utilization rate of assets, and reduces unnecessary equipment investment and idle waste. It reduces the pressure on daily asset management, saves the cost of investing a large amount of manpower and material resources for asset inventory and unnecessary allocation every year, avoids asset loss due to various factors, and improves corporate management efficiency.

[ad_2]