China Post Logistics RFID vehicle management and transportation truck scale weighing anti-cheating system

[ad_1]

Project Background

In recent years, many companies have encountered many problems such as few records, missing records and private vehicles in the transportation of finished products and vehicle management. More and more arrogant man-made mistakes have not only caused serious loss of corporate assets and income, but also formed work habits that are extremely unfavorable to long-term development due to inadequate management measures, which have seriously affected the business management and economy of the company. benefit.

For this reason, the release of a complete set of transportation vehicles and truck scale weighing systems with RFID identification technology has become imminent. It should not only make vehicle management information-based, but the most important thing is that it must be able to use radio frequency identification technology, infrared alignment technology, video surveillance and other technical means to achieve true leak prevention requirements.

The hidden dangers that may exist in the routine weighing process

◆License plates interchanged between carts and carts

◆ The vehicle is not fully weighed on the scale

◆ Collusion to replace goods fraud

◆Circumferentially and repeat weighing on the scale

Losses due to weighing cheating

1. Assuming that the daily number of raw materials in the warehouse for each weighing room is 100 vehicles, and the number of product sales out of the warehouse is 100 vehicles; the price of raw materials per ton = 100 yuan; the price per ton of products = 300 yuan. If only 3% of the vehicles cheated, each vehicle of raw materials stolen 2 tons of weight, and each vehicle of products stolen 1.5 tons of weight. (Assuming that it does not include serious cheating phenomena such as the failure of the weighman to release the vehicle when the vehicle is in the storage or the storage of fictitious materials).

2. Monthly loss of raw materials warehousing = 1 floor scale × 100 trucks × 3% × 2 tons × 100 yuan × 365 days = 219,000 yuan / year;

3. The monthly loss of the product out of the warehouse = 1 floor scale × 100 trucks × 3% × 1.5 tons × 300 yuan × 365 days = 492,000 yuan / year

4. If this is the case for a long time, the loss of the enterprise in one year will be shocking, and the achievements of the enterprise after several hard work will be quietly lost. Therefore, it is recommended to pay attention to the key links of material storage and product storage management. Take effective measures to solve such problems as soon as possible.

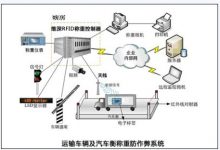

system introduction

Weishen Technology conducts in-depth research on bulk cargo transportation weighing, integrates a variety of advanced technologies based on RFID technology, and cooperates with the automatic weighing management software system professionally developed by Weishen Technology to form a complete weighing of transportation vehicles and truck scales. system. The system uses the vehicle weighing central controller independently developed by Weishen Technology to complete the automatic coordinated control operation of UHF long-distance RFID radio frequency identification equipment, infrared precise locator, video automatic monitoring equipment, vehicle barrier equipment system, signal indicator and other equipment. , To realize the automatic identification and positioning of vehicles, automatic weighing, monitoring and management, etc., to achieve an unmanned weighing room. At the same time, it cooperates with the independent research and development management system of Weishen Technology to realize the whole process, all-round and automatic management of vehicles, personnel, weighing, unloading, access, etc., and provide managers with complete and reliable analysis data and decision-making through rich query and statistics functions. in accordance with.

Introduction to the technical means of the weighing anti-cheating system

Automatic wireless license plate recognition system-anti-replacement license plate

The wireless license plate automatic recognition system is designed to completely eliminate cheating methods of replacing license plates. This cheating method uses vehicles with different tare weights to exchange license plates with similar appearances to achieve the purpose of increasing or reducing the net weight of the goods. This cheating method is very harmful and will cause huge economic losses to the enterprise.

In order to eliminate the cheating method of replacing the license plate, we adopt UHF radio frequency identification technology to eliminate this cheating method. This system issues an RFID electronic label for each vehicle that needs to be managed. The electronic label is pasted on the front windshield of the car with a special high-strength adhesive at a time. If the electronic label is peeled off, the electronic label will be damaged. After the vehicle enters the recognition zone, the vehicle number is automatically recognized. The system will automatically determine the vehicle management data entered in advance. For vehicles with inconsistent or non-existent vehicle numbers and the vehicle number automatically recognized by the system, the system will automatically alarm and prevent the call Heavy.

In addition, this device can scan tags from a long distance to realize non-stop weighing management, reduce the problems caused by human participation and improve the efficiency of vehicle weighing and traffic.

Infrared precise positioning system-to prevent the vehicle from not fully weighing

In addition to RFID vehicle license plate recognition, this system uses an infrared precise positioning system to ensure that the vehicle is fully weighed before proceeding with the weighing operation. This technology completely eliminates the problem of cheating that the vehicle is not fully weighed or that multiple vehicles are weighed at the same time.

Video and image automatic monitoring system-real-time monitoring to achieve subsequent supervision and tracking

The purpose of the video and image monitoring system is to perform real-time video monitoring and image capture of vehicles at the cargo loading and unloading site and weighing site as the basis for future dispute settlement, and to prevent the management personnel and the driver from communicating with the driver to change the types of goods and the high-priced products as low-priced products The problem of cheating in order to achieve profitability.

Weighing anti-cheating control software management system

The weighing anti-cheating control management software system is mainly composed of two parts, the real-time control software subsystem and the weighing management subsystem.

The real-time control software subsystem mainly realizes the automatic collection and automatic analysis of the on-site status through the vehicle weighing central controller with independent intellectual property rights of Weishen, and gives control instructions to the on-site equipment to realize unattended weighing room and unattended access control Function, to realize the functions of automatic alarm, remote supervision and log monitoring for abnormal situations. At the same time, the field control data is tightly integrated with the weighing management subsystem.

The weighing management subsystem is a comprehensive management platform for personnel, vehicles, and weighing services, including: system management, authority management and commodity management, customer supplier management, vehicle admission, vehicle delivery, cargo tare weighing, and gross cargo weight , RFID electronic label issuance management, data backup, data recovery, factory entry record query, factory goods query, weighing room weighing flow query and other functional modules.

The main function of cargo weighing and cargo vehicle management is to carry out cargo weighing and cargo vehicle entry and exit management. Through the designed function (program), it is provided to all managers who need it, so that they can view the status of the vehicle in the factory in real time. Change, carry out targeted regulation on in-plant business, and realize effective control of in-plant vehicles.

Specific cargo weighing and freight vehicle management can achieve the following functions:

1. Adopt user hierarchical management, use specific functions according to permissions

2. The problem of network weighing in each pump room is solved, so that each weighing room can realize network weighing;

3. Statistical analysis of goods leaving the factory and raw materials entering the factory;

4. Monitor the vehicle’s business process of entering, weighing, and leaving the factory, record the problems that occur, and generate corresponding query statistical reports, which is convenient for the management personnel in the factory to perform statistical analysis, find problems, improve operating efficiency, and reduce each Management loopholes in links.

5. Extensible data interface can be used for data exchange and system integration with other enterprise information systems (financial systems, ERP, etc.).

success case

Since the application of the system in 2005, it has been successfully applied in China Post Logistics, steel plant steelmaking fuel, power plant fuel, bulk cement sales and weighing, and raw material automatic weighing. After the implementation of the system, it has not only avoided multiple weighings for enterprises The loopholes in vehicle management have also improved the automation and information level of enterprise transportation vehicle weighing.

[ad_2]