Pork Food Safety Traceability System in Six Districts of Chengdu City Center and Shuangliu County

[ad_1]

business background

According to data from the China Meat Association, in 2008, the national meat per capita was 54.8 kg, of which pork was 34.8 kg. Pork products accounted for more than 60% of the entire meat products. Pork hygiene and quality safety are directly related to the health of the people. And life safety. However, the current technical management level of the pig slaughtering industry in my country is backward, and the whole-process supervision system covering pig breeding, slaughtering, processing, circulation and consumption has not yet been formed, which poses a greater hidden danger to pork quality and safety. On June 1, 2009, the Food Safety Law was formally implemented, setting specific requirements for the production, processing, packaging, transportation, and sales of meat products. In order to ensure the effective implementation of the Food Safety Law and its implementation regulations, the Ministry of Commerce, together with the Ministry of Finance, has carried out pilot work on the establishment of a service system for “safe meat” in 10 provinces and cities across the country, exploring and trying a variety of methods and experiences to ensure pork quality and safety It will take 3 to 5 years to form a new mechanism for the healthy development of pig slaughter and meat circulation industries across the country.

In 2009, Premier Wen Jiabao expounded the new concept of “perceive China” IoT sensing technology during his inspection tour in Wuxi, marking that China’s “Internet of Things” has entered the actual construction stage. Therefore, the key technology of combining the RFID electronic tags of the Internet of Things and the intelligent network with the IC card is fully forward-looking in the application mode of the quality traceability system of pork products, and it can be adapted to today’s without framework adjustments within 3 to 5 years. The rapid development of China’s social economy and technology suits China’s national conditions. The use of RFID technology combined with network and information systems for data collection and communication can improve the efficiency of information collection and transmission, effectively identify meat products, and integrate scattered information, thereby solving the difficulties of the meat product traceability system , To achieve the entire information tracking and tracing need to achieve seamless links in all links in the supply chain.

Application goal

Yuanwanggu raw pork quality information traceability system has established three major systems in accordance with the Ministry of Commerce’s “Reliable Meat” service system, namely the slaughter supervision support system, the meat quality safety traceability system, and the meat cold chain management system. Incorporate pig breeding, slaughtering and meat processing, transportation, wholesale, retail, etc. into the entire online supervision of the pork supply chain, so that the limited supervisory personnel of government departments can remotely manage any link that needs supervision no matter when and where. And supervision, real-time retrospective verification can be carried out for each link of the source of pork products to ensure that the accountability is accurate and timely in the event of food safety incidents, and the early warning and recall measures are effective and in place. For consumers, they can also be verified and compared when buying pork products.

introduction

Yuanwanggu Company combined with the implementation of the Pork Product Safety Traceability System in Chengdu in 2009, and put forward the “government management model innovation to guide technological innovation, high-tech transformation of traditional industries, high-efficiency and low-cost operation to drive supply chain business process optimization.” The solution provides a complete hardware and software solution for the three major systems in the “Safe Meat” service system-the slaughter supervision support system, the meat quality and safety traceability system, and the meat cold chain management system.

Yuanwanggu raw pork quality information traceability system is for the management of pig farms, designated slaughterhouses, cold chain transportation links, meat wholesale markets, meat stalls in farmers’ markets, large supermarkets and hypermarkets, and catering companies in the management area. And the quality and safety traceability system of pigs and meat products of designated units. It uses the RFID electronic tags bound to live pigs and pork to associate with the different IC identity card information of various business users in the supply chain, and uploads the changes in the flow of pork in the supply chain to the central database in real time through wireless transmission technology, not only for each business user Log in to the platform system according to the authority to obtain daily business data stored in the government data center at any time, and various government business departments can also implement online supervision of all links in the supply chain according to their own jurisdictions, which provides a good way to ensure the safety of pork food. Technical support means.

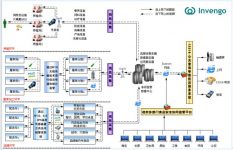

system design

In view of the characteristics of the safety supervision of raw pork products, the system is divided into two parts: the front-end data hardware collection end and the back-end data management software end. The front-end data collection is based on the RFID core technology for real-time monitoring of the relevant production site activities of fresh pork; the back-end data management is the use of government business systems to manage the real information reported in each link and the statistics and analysis of the front-end collected data , Distribution, etc., as shown in Figure 1.

Implementation benefits

Optimize the information management process of pork production and circulation enterprises;

Improve the supervision efficiency of government supervision departments;

Fully satisfy consumers’ right to know pork quality and safety information;

When a food safety accident occurs, the accountability is accurate and timely, and the early warning and recall measures are effective and in place;

After the completion of the system, the pork safety issue has been resolved.

success case

In September 2009, the Chengdu Municipal Government began to fully implement the pork food safety traceability system in the six central districts of Jinjiang, Qingyang, Wuhou, Chenghua, Jinniu and High-tech Zones and Shuangliu County, namely 79 designated slaughterhouses and large-scale agricultural product wholesalers in the city. Markets, more than 500 farmer’s markets (8,000 pork stalls), 17 large supermarkets (including branches), 19,000 catering companies and designated units have fully implemented the implementation and construction of a traceability system for pork quality and safety.

System highlights

In accordance with the Ministry of Commerce’s “Meat Reliable” service system, the system has established three major systems, namely the slaughter supervision support system, the meat quality and safety traceability system, and the meat cold chain management system. Starting from the pig breeding link, through the real-time information binding of different forms of RFID tags and RFID identity cards of supply chain business personnel, the quality information and data upload and download are automatically linked to the downstream wholesale and retail links through mobile wireless communication technology to realize The forward tracking of related information from pig farming to the meat retail terminal has also realized the reverse traceability of related information from the meat retail terminal to pig farming.

[ad_2]