The successful application and solution of the RFID technology of the Aerospace Gold Card in the field of Olympic food safety

[ad_1]

1. The application case and scope of application of the aerospace gold card food safety (RFID) traceability management system:

In August 2008, Beijing successfully hosted the 29th Olympic Games, an unprecedented sports event. Food safety involves personal safety and international image. It is a material guarantee for the successful hosting of the Olympic Games. For this reason, in early July 2005, Beijing launched the “Food Safety Action Plan” to address the production, processing, transportation, storage, packaging, and packaging of food. Monitoring and traceability are carried out in various links such as testing and sanitation.

Food circulation not only involves many links such as production, processing, transportation, warehousing and distribution, but also monitoring and management of manufacturers, logistics companies, and transportation vehicles. This requires a food safety management system to monitor the flow of food. It can facilitate information collection, transmission, summary, and query. Combining these factors, a food safety management system based on RFID technology is an ideal choice. Through a responsive back-end information system, food can be monitored from the source to the final consumer, thereby strengthening food safety management.

Aerospace Gold Card proposed a food safety (RFID) traceability management system solution based on the characteristics of food safety. The system uses RFID electronic tags as the basic mobile data carrier and basic information unit, and adopts advanced information transmission technology, computer network technology, and database technology to make food management form a complete dynamic and real-time human-machine system to ensure food safety. The system has been successfully applied during the Beijing 2008 Olympic Games, and is currently continuing to be used in food safety traceability business.

The Aerospace Gold Card Food Safety (RFID) traceability management system can be widely used in the traceability management of agricultural, forestry, fishery, animal husbandry, and sideline foods. It is suitable for grain and oil food, livestock and poultry food, fruit and vegetable food, aquatic food, condiments, and dairy products. Products, convenience foods, baby foods, food additives, beverages, cosmetics, health foods, etc. Therefore, the system will not only realize the food safety traceability management of the 2008 Beijing Olympic Games, but will also be widely promoted and applied in the future food safety management. The Aerospace Gold Card will customize corresponding standardized RFID solutions for various food companies as food safety traceability The enterprise end system of the management system collects relevant information in real time and transmits it to the central office management system to realize the supervision and management of various food enterprises by various relevant departments.

2. Importance and urgency of food safety

In recent years, due to the frequent occurrence of food safety crises, which have seriously affected people’s health, they have aroused widespread concern around the world. The European Union, the United States and other developed countries and regions require that all food exported to the local must be tracked and traced.

In our country, the occurrence of a large number of incidents such as SARS, avian flu, and food poisoning have seriously affected people’s lives, and they have also attracted great attention from the country. In 2006, the Ministry of Health received a total of 596 food poisoning reports nationwide, with 18,063 poisonings and 196 deaths, including 17 food poisonings involving more than 100 people.

The recent infant milk powder incident has sounded the alarm for food safety monitoring, aroused the attention of the central leadership and the worries of the people across the country, and also aroused the world’s attention to China’s food safety. How to ensure food safety has become an urgent matter.

3. Brief introduction of the aerospace gold card food safety (RFID) traceability management system

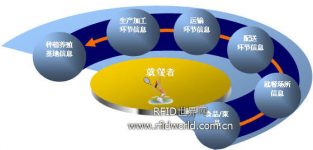

The Aerospace Gold Card Food Safety (RFID) Traceability Management System uses RFID technology and relies on network technology and database technology to realize information integration, query, and monitoring. It provides safety and security for each piece of goods for each production stage and the process of distribution to the final consumption field. Reasonable decision-making on the source of food ingredients and inventory control to realize the food safety early warning mechanism. RFID technology runs through food safety, including production, processing, circulation, and consumption. The entire process is strictly controlled. A complete supply chain food safety control system has been established, forming an open-loop application for various food companies from production to sales. In order to ensure the provision of high-quality and assured food to the society, and to ensure high-quality data exchange in the supply chain, the food industry can thoroughly realize the source tracking of food and the transparent management of the food supply chain.

Figure 1: Flow chart of food safety management system

4. The characteristics of the aerospace gold card food safety (RFID) traceability management system:

1. Use the characteristics of RFID to achieve food safety and traceability management, which is more efficient, real-time and convenient than the record file traceability method;

2. Provide completely transparent management in the food supply chain to ensure the entire visual control, monitoring and traceability of food safety;

3. It can comprehensively monitor the source pollution of planting and breeding, the additives and harmful substances in the production and processing process, and the safety hazards in the circulation link;

4. It can effectively assess potential food safety hazards and provide a basis for scientific early warning;

5. The data can be reported in real time and accurately through the network, which is convenient for faster and more in-depth analysis and research;

6. Through the Internet, consumers can inquire the complete tracking information of the food purchased.

5. Advantages of aerospace gold card food safety (RFID) traceability management system:

1. Passive electronic tags can be easily carried due to their small size and low cost, which can be accepted by many commodities;

2. Apply active tags on logistics vehicles, which can be reused, have a long transmission distance, and carry a large amount of information, which can carry temperature information and vehicle location information;

3. The information can be completely stored in the entire logistics process, and it is not easy to lose and change, and it can be easily and quickly inquired and other operations.

6. The label form of the aerospace gold card food safety (RFID) traceability management system:

In view of the characteristics and needs of different stages, the aerospace gold card food safety (RFID) traceability management system chooses label forms and label reading forms in different stages and different logistics processes.

1. In the production stage, the electronic label mainly records production and breeding related information, such as farm number, shipping time, shipping batch, etc., and this information should be linked with the production company’s own information system database to query the production process Details of the information. RFID card reader/writer equipment is installed in each production enterprise, which can realize the writing of food information;

2. In the processing link, the electronic label used contains the relevant data of the food in the production process and the information added in the processing link, such as the processing company number, processing date, processing batch, etc. This information is associated with the company’s local database for easy inquiries by the food management center. Processing companies and food importing companies are equipped with RFID read-write devices;

3. In the transportation link, the electronic label data content used for container transportation includes food information in the container, food temperature information, vehicle location information, delivery vehicle information, and delivery time. This information is associated with the local database of the logistics company;

4. In the warehousing link, for foods that are not equipped with RFID electronic tags, labels can be installed on the food in the food warehouse, the original food information is associated with the label, and the installation time and batch are recorded. Inside the warehouse, RFID electronic tags are worn on forklifts or staff, which contain the ID numbers of employees or forklifts, which can effectively use resources and make the storage process more efficient and faster;

5. In the food distribution link, the content of the electronic label of the distribution vehicle is basically the same as the transportation process.

7. The composition of the aerospace gold card food safety (RFID) traceability management system

Aerospace Gold Card Food Safety (RFID) Traceability Management System includes the following systems:

1. Food Safety Management Center;

2. Food special warehouse system;

3. Food processing center system;

4. Food logistics enterprise system;

5. Food production and breeding base system;

6. Food point of sale system;

7. Food transportation monitoring point system.

Figure 2: The overall structure of food management safety

8. About the scale of aerospace information and its RFID business

Aerospace Information Co., Ltd. is a state-owned high-tech enterprise with modern enterprise management mechanism integrating technology, industry and trade. It has more than 40 branches and subsidiaries and more than 700 grassroots service units. The company focuses on information security and is committed to the development, production, system integration and promotion of computer system applications. It has undertaken national key projects such as “Golden Tax Project”, “Golden Card Project”, and “Golden Shield Project” for 8 consecutive years. Ranked among the top 100 electronics companies in the year, it is one of the most powerful IT listed companies in China and the backbone of state-owned enterprises.

In order to realize the industrialization of RFID, Beijing Aerospace Gold Card Branch, which specializes in IC card R&D, production and application, is fully involved in the field of RFID, engaged in the R&D and production of electronic tags and their reading and writing equipment, antennas, and the design of system application projects. Implementation etc.

Aerospace Gold Card has a number of technical patents, a number of products have won the title of “National Key New Product”, has multiple contact card and non-contact card production lines, and has many years of management experience in large-scale production. Aerospace Gold Card’s expressway products have served the expressways of more than 20 provinces, autonomous regions, and municipalities across the country. At the same time, it is one of the designated production units of the second-generation resident ID card (environmental protection and high temperature resistant non-contact card) of the Ministry of Public Security.

It can be seen that the Aerospace Gold Card has made remarkable achievements in the research and development, production and application of smart cards. Since 2006, we have used the traditional advantages in the field of smart cards to fully enter the field of RFID applications, and have made necessary R&D reserves and production preparations. In 2005, the RFID demonstration center was established to test and research the application environment and technology development of the RFID system, and at the same time demonstrate the mature RFID technology application system of the Aerospace Gold Card. The demonstration center covers an area of more than 300 square meters, covering the application of three RFID frequency band tags of 13.56MHz, 915 MHz, and 5.8GHz. The demonstration center provides visitors with a real RFID technology application experience by establishing an actual RFID demonstration environment; 2006 Introduced a full set of RFID production lines in the year, which can realize product manufacturing from antenna design and manufacturing to INLAYS bonding and label compound processing; in 2007, a product inspection and testing center and microwave laboratory were built; a series of RFID applications were launched Projects, such as electronic ticket system, open access control system, item traceability system, food safety traceability system, etc., have the necessary conditions for engaging in the application of RFID technology. After a series of hard work, Aerospace Information is now one of the most influential smart card companies in China, one of the vice chairman units of China RFID Industry Alliance, one of the top ten most influential RFID companies in China, and RFID information security. Leading unit for standard setting.

[ad_2]