RFID technology ensures the road surface quality of Taipei Luping Project

[ad_1]

I believe that many car and locomotive users have the painful experience of encountering rugged potholes and manhole covers (commonly known as manhole covers) when driving on flat roads. If they are caught early, they may be able to dodge smoothly. If it is not enough, it will be uncomfortable from the bumps of the vehicle, and it may endanger the safety of people and vehicles and cause irreparable regret. The above-mentioned poor road quality problems criticized by people have long troubled the life safety and driving comfort of countless passers-by. Such annoying road conditions have also led the Taipei City Government to launch a road leveling project. Starting from the pavement renewal project of Sections 4 to 6 of Zhongxiao East Road, road quality improvement projects will be implemented successively for some sections of Taipei City. For this reason, people who have recently passed through sections 4 to 6 of Zhongxiao East Road will definitely notice the red banners along the road: “Scar removal will begin on this section of the road from March 26” and “The road must be leveled and removed first. Skin resurfacing after scar” and so on.

However, apart from the peculiar slogan similar to plastic cosmetics advertisements, compared with the previous road construction, what is special about this major project concerning the rights and safety of passersby in Taipei City? It became the starting point for this U-CAR special report. Taking the road surface renewal project of section 4-6 of Zhongxiao East Road as an example, I personally interviewed the Taipei City Government Maintenance Engineering Team to learn more about the improvement of road quality by the Taipei City Road Flat Project. , The proposed new engineering thinking and concrete actions.

The shortcomings of traditional road construction methods and manual hole maintenance

As the saying goes: “Frozen three feet is not a day’s cold.” The problem of poor road quality in China is not a matter of three days and two nights. However, before introducing new road construction and maintenance methods, it is still necessary to trace the source to explore the shortcomings of traditional construction methods in order to clarify the key to poor road quality. Cause.

After being summarized as a whole, the key factors affecting road quality mainly include problems such as poor roadbed, low road durability, and uneven manholes. In the past, when roads were milled and refurbished, the asphalt concrete was resurfaced after the pavement was fully milled, and the roadbed was not strengthened for the roadbed section that has been damaged. This often caused the roadbed to be caused by rainwater leakage after the pavement was milled and paved. The problem of insufficient hardness makes it easier to crack and damage after vehicles are driven intensively day and night.

Another interlocking problem lies in the material used for milling and paving in the past. The largest batching is 3/8-inch asphalt concrete (grade batching refers to the graded batching, and the previous used batching is the largest particle 3/8-inch gravel grade) At the same time, when the thickness of asphalt concrete is only 5 cm, although the cost of road construction is low, it is easy to cause the problem of insufficient road strength and thickness when heavy trucks are driving, resulting in insufficient road durability and more susceptibility to the heavy pressure of trucks. Deformation and other issues.

In addition to poor roadbed and low durability of the road surface, the biggest factor affecting road quality is the unevenness of manholes and the major problems of excessive manholes on the road. In the past, when the government opened roads, various pipelines were not included in the unified scope of implementation (currently only along the Civic Avenue and the newly built MRT in Taipei City, taking the opportunity to implement the integration of underground common ditch pipelines instead of traditional manholes), resulting in coverage of telecommunications , Electric power, tap water, cable television, gas and other industries, each laying and maintaining manholes.

The manholes of different units have their own ways, which also caused the traditional road milling to avoid the manhole blocks and hand them over to each unit to adjust the manhole and pavement. In this mode, there is no uniformly followed high-level road specifications (based on the road surface). There is no uniformity based on the manhole cover or the manhole cover), coupled with the difference in the construction specifications and finished quality of the maintenance project, resulting in the unevenness of the manhole hole and the unevenness of the road in the future, which will become a tumor that affects the quality of the road.

Subgrade improvement and increase of road thickness

The road leveling project initiated by the Taipei City Government’s establishment of an inter-bureau division team in May 2008 is actually a plan for fundamental solutions to the poor quality of domestic traditional urban roads after investigating the construction process of Japanese roads. Of course, the focus of the solution is officially around the road problems mentioned in the first half of the article. After U-CAR interviewed Lin Kunhu, the leader of the Maintenance Engineering Team of the New Engineering Office of the Taipei City Government Works Bureau, and observed the pavement renewal project of Zhongxiao East Road, I simplified and sorted out the characteristics of the road surface renewal project.

The first is to improve the poor subgrade. Take the 4~6 section of Zhongxiao East Road as an example. After the investigation by the engineering unit, there are 337 places. The subgrade of about 6881 square meters is judged to need improvement work. The construction method is in accordance with The scope is divided into different sizes. For those whose area needs to be improved to be 1.5 meters by 3 meters or less, adopt AC (asphalt concrete) full-section layered rolling reinforcement. For those who exceed this range, use on-site batching and dry-mixed cement crushed stone gradation. Improve to solve the impact of poor local roadbed on the quality of road re-milling.

Next, in response to the problem of low pavement durability, the new engineering specifications were also implemented in the Zhongxiao East Road Pavement Renewal Project. After the milling operation of the old 5 cm thick asphalt concrete pavement is completed in the future, the new road will be converted to milling 10 Centimeter thick asphalt concrete, and at the same time, the largest particle size of crushed stone will be increased from the old 3/8 inch to 3/4 inch to improve road durability. According to the information provided by the maintenance team leader Lin, Zhongxiao East Road 4~6 will adopt the new standard milling road area to reach 140,612 square meters by then.

Change to day construction and completion maintenance for 6 hours

In addition to the improvement of roadbed and the increase of road-level ingredients, road construction period and completion maintenance time actually play a key role in road quality, but this has been mostly ignored in the past. Therefore, focusing on improving the quality of construction, the municipal government has already decided on the future road renewal project to adjust the previous night construction to day construction.

In this regard, Captain Lin stated that it is a major decision to adjust to day construction. In addition to considering that there is sufficient light during the day, road construction quality control can be implemented, especially the control of road surface milling and paving. On the other hand, it also changes the previous considerations. Traffic needs during the day, and the mode of opening the vehicle driving mode at night when rushing to milling and paving at night will easily cause the temperature of the newly milled asphalt concrete to be lowered and affect the hardness of the road surface. Once the vehicle is rolled, it will be easily damaged and deformed; therefore, the new construction law stipulates After the construction is completed, the road must be maintained for 6 hours or wait for the concrete temperature to drop to 50ºC before allowing the road to solidify and then pass to traffic to avoid rapid road wear.

Lowering the height of manhole cover, reducing manhole cover and unified maintenance

The resolution of the manhole problem can be regarded as the core major change in the road surface renewal project implemented by the Luping project. After a detailed interview with U-CAR and the maintenance engineering team, the maintenance engineering team stated that there are five major items in the manhole project innovation: lowering the height of the manhole, reducing the manhole, embedding the RFID radio frequency marking system in the manhole, and unified maintenance.

First of all, the original road construction process that ignores manual holes is changed. The road surface renewal project implemented this time is to first carry out concave and convex manual hole lowering operations. Also take the 4~6 section of Zhongxiao East Road as an example, calculated by the engineering unit This 5649-meter section of construction has a total of 1132 manholes. Among them, there are nearly 75% of 857 manholes. Lowering must be carried out first (the remaining 275 manholes are fire hydrants, water valve holes and (Wascon, etc., due to public safety, the authority and responsibility unit will cooperate with the construction to adjust the level).

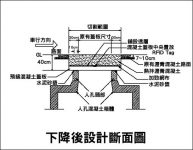

As for the manholes that require unified lowering operations, the construction unit will confirm that the lowering depth is 40 cm or 15 cm in conjunction with the existing manned holes on the road surface and the pipeline unit. Regarding the consideration standard for lowering the height, Captain Lin said that according to current statistics, there are about 30% of the manholes, which are no longer functional after the completion of the preliminary pipeline burying operation. Therefore, they will choose to perform the manual hole edge stone knocking and hole cover adjustment. After the drop of 40 cm, the RC cover plate covering the thickness of 15 cm is closed to realize the reduction of manholes. As for other manholes that still need to be opened in the short term, they chose to reduce them by only 15 centimeters to facilitate manhole adjustments when they are opened in the future.

After knocking out the edge stone of the hand hole and reducing the hole cover by 40 cm, the RC cover plate covering the thickness of 15 cm is closed to realize the reduction of the hand hole.

At the same time, an RFID radio frequency marking system is placed in the center to facilitate future detection and tracking of the location of the human hand hole.

The barcode of the sensor chip of the RFID radio frequency marking system is embedded in the round cement tray, and the file number of the hand hole is on it.

Before backfilling the asphalt concrete to bury the manholes, in order to facilitate the accurate identification of the manhole positions after road improvement, the engineering unit will bury each manhole cover with an RFID radio frequency marking system. In the future, engineers only need to use RFID to detect The device can accurately find the position of the manhole under the road that is individually numbered and filed. Finally, since the manhole has been reduced to less than 15 cm, the construction manufacturer will finally be able to fully replace the pavement according to the design elevation and milling thickness (10 cm). After completion, the manhole that is only reduced by 15 cm will remain away from the road surface. There is 5 cm thick asphalt concrete, which means that most of the traditional exposed manhole covers will be hidden under the road surface. As a result, the smoothness of the road surface will be significantly improved.

Before backfilling the asphalt concrete to bury the manhole, in order to facilitate the accurate identification of the manhole position after the road has been improved, the engineering unit will bury each manhole cover with an RFID radio frequency marking system. It can accurately find the position of the manhole under the road that is independently numbered and filed.

Finally, Captain Lin also foretells the direction of road manhole maintenance in the future. In the past, different units will open and close, lower and upgrade the construction operations separately, and gradually integrate them into the unified construction by the public works unit to reduce the frequency of road manhole construction and ensure manpower. The engineering quality of the hole adjustment is still being negotiated and integrated by the government unit, and there should be clearer news in the near future.

The effectiveness of the new construction method, ready to be used by passers-by

Since 1997, the Taipei City Government is expected to compile a total budget of 4.9 billion yuan in three years to implement the road leveling project. Since 1997, the new construction method of 11 roads has been gradually tested, and 77 road renewal plans have been completed. Paintings, including sections 4-6 of Zhongxiao East Road and section 1-2 of Xiyuan Road, which are currently under construction, are scheduled to be completed in June and May. At that time, the height of manholes will be lowered and strengthened. The actual effect of milling and paving will be subject to personal acceptance by all passers-by. Not only that, U-CAR will also continue to track and report the follow-up progress of the Luping project based on the standpoint of safeguarding the rights of passers-by and improving road safety.

[ad_2]