Application of RFID solutions in the automotive industry

[ad_1]

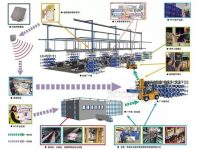

Among Dematic’s many real-time logistics solutions, the line-side material pull call system is a solution based on RFID technology and applications for the production line of the automobile assembly plant.

In the Chinese automobile market, many models are in short supply. Full-load operation of production lines and parallel production of different models have become the development trend of the automotive industry. Generally, the daily production volume of the final assembly plant is controlled by scheduling, which serves as the basis for the logistics department to feed materials to the production line. The feeder only estimates the feed volume of a fixed output based on experience, and cannot really grasp the actual material consumption of the assembly line. Even if a lineman is configured, the problem cannot be solved fundamentally. In order not to stop the final assembly line, the feeder must ensure that the material inventory at the side of the production line is at a high safety level. These materials are large in quantity and occupy a large area. On the one hand, the operation space of the final assembly line workers is reduced, and on the other hand, it causes difficulties in retrieving materials and affects the normal efficiency of the operation line. The material inventory and increased staffing also make the cost of the final assembly plant remain high.

Therefore, the supply of materials beside the line is the key. Dematic started with the supply of on-line materials and designed an RFID on-line material pull call system, which has a leading position in the world to improve the real-time transmission of on-line material demand information and improve the timeliness of on-line material supply. , Thereby improving the overall assembly efficiency of the entire production line, and at the same time, reducing the configuration and cost of line inspectors. At present, large companies such as FAW-Volkswagen, Shanghai Volkswagen, Shanghai GM have implemented Dematic’s solution, and this innovative application will also be promoted in other final assembly lines.

Dematic’s real-time logistics team is the world’s leading integrator of wireless networks, RF terminals and IT solutions to help customers realize end-to-end supply chain visualization and real-time information management, optimize management accuracy and reliability, and improve customer service Level, so as to effectively control the cost of the supply chain. Dematic provides one-stop services for data collection and analysis, planning and design, project implementation and commissioning to after-sales service. At present, Dematic’s real-time logistics team has deployed wireless networks in hundreds of logistics bases in Asia, integrated tens of thousands of RF terminals and voice picking terminals.

[ad_2]