Overview of RFID technology and application of vehicle identification

[ad_1]

1. Overview of RFID technology:

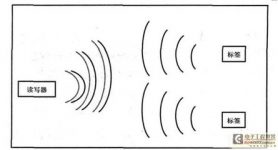

Radio frequency identification (RFID) technology refers to a method of identifying items realized by radio technology. The basic principle of radio frequency identification is to attach an electronic tag to the item to be identified. When the item attached with the electronic tag passes through a specific area, another important device of the radio frequency identification system can read out the information in the electronic tag. The stored information is read out in a contactless manner and sent to the computer. The working principle of the radio frequency identification system is shown in the figure.

electronic label

The electronic tag is a key component of the radio frequency identification system. An electronic tag is usually composed of an electronic tag antenna and a dedicated chip. The electronic tag (or electronic tag dedicated chip) itself is an electronic system. The electronic tag stores the identifying information of the item to be identified, and when it receives the inquiry signal sent by the reader, it transmits the unique identification information stored by itself to the reader in a wireless manner. The identifying information of the item to be identified in the electronic tag is stored in the storage chip in the electronic tag in the form of electronic data.

Reader

The function of the reader is to read the information in the electronic tag on the one hand, and to write information into the electronic tag on the other hand, which is why it is called a reader. The specific area through which the electronic tag mentioned above passes is called the read-write area of the RFID system read-out device. The characteristics of the read-write area are determined by the antenna of the read-out device, the radio frequency power emitted by it, the reflection performance of the electronic tag, and the sensitivity of the read-out device to receive signals.

The distance between the reader and the electronic tag when it can read the information in the electronic tag is called the recognition distance.

Schematic diagram of radio frequency identification (RFID) system

2. Three-dimensional garage vehicle identification system

The three-dimensional garage vehicle identification system adopts ultra-high frequency RFID technology (915MHZ) to realize the long-distance recognition of vehicle information, and transmits the corresponding information of the vehicle and the garage, such as the parking space number and the payment status, to the garage control system to achieve rapid Features such as parking, quick pickup, and non-stop charging.

The system can realize functions:

One card for one vehicle, through the radio frequency smart card to transmit information to the plc data center, to realize the automatic parking and retrieval of each vehicle without human operation.

Temporary vehicle management: Temporary tags can be applied to foreign vehicles. At the place where the tags are handled, authorization is granted by writing restricted time information to the tags, and the time period for vehicle entry and exit can be restricted. For over-limit vehicles, the system will give an alarm.

In order to make the operation simple, convenient and friendly, the system adopts a full Chinese menu operation interface.

The system can provide complete financial management functions and automatically form various reports.

The scrolling LED Chinese electronic display prompts make it clear to users and managers.

The fully intelligent logic self-locking control system for vehicle entry and exit, strictly controls the entry and exit behavior of cardholders in line with the requirements of “one card, one vehicle”.

Special handling functions for special vehicles.

The system has good compatibility and expandable functions.

3. The basic composition of the system:

The reader and the microwave identification card installed on the vehicle constitute the core of the information transmission of the system.

The reader is connected to the plate antenna through a coaxial cable, and is connected to the PLC of the stereo garage through the communication line. The reader is preset with the RS232RS485WG26WG34 standard transmission interface, and has the ability to make adjustments according to the requirements of the PLC.

Parking workflow:

1. Vehicle approaching recognition range (0~~10 meters);

2. The reader recognizes the vehicle (electronic tag) information, such as the parking space number, entry time, vehicle owner information, etc., and transmits it to the PLC in real time (50 milliseconds);

3. PLC control garage is ready;

4. The vehicle enters the parking area and stops.

Work process of picking up the car:

1. The vehicle owner is approaching the recognition range (0~~10 meters);

2. The reader recognizes the vehicle (electronic tag) information and transmits it to the PLC in real time (50 milliseconds);

3. The PLC will transfer the corresponding car to the driving area;

4. The owner arrives at the pickup area and picks up the vehicle.

4. Equipment performance parameters:

1. Reader:

Read-write label Electronic label conforming to ISO-18000-6B standard

Working frequency 902-928MHz (may vary slightly depending on the country or region)

Working mode: work in broad-spectrum frequency hopping (FHSS) or fixed frequency transmission mode

Output power 27—32dBm (adjustable between 27—32dBm, factory setting: 32dBm

Reading distance Reading distance ≥ 8m, writing distance ≥ 3m

The card reading speed averages 6ms per 32bits reading time

Write card speed average write time 50ms per 32bits

The security mechanism can check the legality of the electronic label

The number of cards read at a time has the function of anti-collision detection, and 30 electronic tags can be read in batches at a time

The card reading mode automatically reads the card at regular intervals, and can also be controlled by the input trigger signal or command

Power supply is equipped with a 220V AC input + 5V/4A DC output power converter

Average power ≤ 12W

Dimensions 225mm&TImes;166mm&TImes;39mm

Weight: Aluminum alloy shell, the weight of the whole machine is about 2Kg

Working temperature -20℃~+70℃

[ad_2]