RFID application case of Guangzhou Automobile Honda container storage and return

[ad_1]

For the application of RFID in the logistics container management of the automotive industry, Guangqi Honda was the first person to eat crabs. As everyone knows, the logistics turnover box management of the automobile industry has always been a difficult problem. Many OEMs suffer from loss, destruction, and improper misappropriation. There is a 10-15% loss and damage rate every year. Some OEMs set the container replenishment rate at 30% per year. Therefore, how to manage logistics containers and make production run stably is also a problem that many automobile OEMs are striving to solve.

RFID technology emerged during World War II, but for various reasons, there are few practical cases applied to the civilian logistics industry. In the early years, it was used for the management of fast-moving consumer goods, such as clothes and medicines. In the automotive industry, although major OEMs have done a lot of in-depth investigations and studies, they have not been able to easily get started. Therefore, when Guangzhou Automobile Honda started the RFID project, it must have been struggling to think about it.

1. Project introduction

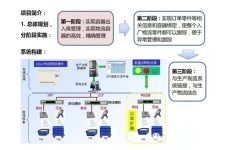

RFID is mainly used for container management in two stages. The first stage is mainly to realize the in and out management of containers and realize the efficient and accurate management of logistics containers. The second stage is to realize the binding of order and container information, so that the entire inbound logistics parts can be tracked.

2. Implementation steps of the first stage (2 steps)

2.1. Chip preparation stage

The specific process is to encode the container according to the information of the container type provided by the supplier. After encoding, use the RFID reader to write the chip. After the chip is written, it is distributed to the supplier. The supplier affixed RFID tags to the containers in accordance with Guangben requirements. In addition, in order to ensure that the container can still be read on the system when the RFID chip fails, Guangqi Honda requires a one-dimensional barcode to be attached to the container. When the RFID cannot be read normally, the barcode scanner can be used to scan.

After the specific parts arrive, the receiver turns on the RFID device to set the system. The unloading personnel pull the parts through the RFID logistics door, and the receiving personnel confirm the accuracy of the data. When loading and unloading containers, the RFID equipment is also opened by the container recycling personnel, and after setting the system, the containers are loaded and unloaded. Finally, the system will print out a triplicate container recycling form, signed and confirmed by logistics providers, suppliers, and loading and unloading personnel. Each link of data information is uploaded to the EPS system for relevant personnel to inquire.

Hardware and software investment: The three major hardware of the general RFID application system include tags (Tag), reader (Reader) and antenna (Antenna). In terms of hardware preparation, Guangqi Honda invests in the construction of the RFID system on its own. Part of the reading equipment in the factory is funded and constructed by Guangqi Honda. In terms of chips, considering the investment cost and the convenience of promotion, 12 suppliers and logistics companies were selected for demonstration at the initial stage. The chips for demonstration were provided by Guangqi Honda for free.

[ad_2]