Kiremko launches RFID potato cutting equipment management system

[ad_1]

Kiremko, a Dutch potato processing equipment provider, has launched KnifeGuard, an RFID system for managing the knife blocks installed on the company’s QuadraFlow potato cutting machine. The knife block is a detachable and replaceable cube unit, which contains a sharp blade, which can be selected according to the cutting size of the potato. In the QuadraFlow machine, the water flow pushes the potato to the nozzle of the tube, and then uses a blade to cut it into pieces.

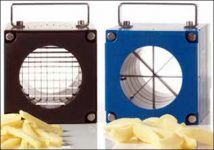

(The knife block has different cutting blade structures to obtain potato slices with corresponding shapes)

In the KnifeGuard system, a passive 13.56 MHz RFID tag is attached to each tool block, and an RFID reader antenna is installed in the tool so that the tool tag can be read at any time. The tag data will then be sent to the processing unit and can be read by a programmable logic controller (PLC). If the processing unit detects an incorrect configuration, it sends a warning signal to the PLC so that the user can know in advance.

The KnifeGuard system includes a programming unit, an RFID reader and an LCD screen. After the user places the tool block with the RFID tag on the programming unit, the reader will automatically read the tag, and then display the detailed record of operation and grinding. If the tool has been used, the history record will be updated. This helps the operator determine whether the knife needs to be sharpened again.

(The knife block is installed between the inlet and outlet pipes of the QuadraFlow machine)

Eric van Oorschot, Kiremko’s innovation manager, said: “The development of KnifeGuard was inspired by the box handling system of a large store-these boxes use labels and constantly changing content.” Using RFID technology, Kiremko created a contactless system that can Each knife block is identified, and permanent data (cut size of the knife block) and temporary data (hours of use of the knife block) are stored.

van Oorschot said that Kiremko’s KnifeGuard development team investigated several RFID equipment suppliers. After a series of tests, the team chose Turck’s tags and readers. These tags and reader antennas can withstand water and physical Impact and run well in a machine made of stainless steel. Kiremko was responsible for the development of the KnifeGuard software.

[ad_2]