Tea product safety traceability system

[ad_1]

【System Overview】

In recent years, the frequent occurrence of tea quality and safety crises has aroused widespread concern among consumers. To ensure the quality and safety of tea products, the products must be traceable. The “tea product safety traceability system” uses automatic data collection technology to uniquely identify and link the management objects of the supply chain links such as the growth, processing, storage and retail of tea raw materials. Once the tea has safety problems, these signs can be used to trace back to accurately narrow the scope of tea safety problems, find out the links where the problems occur, and even trace back to the source of tea production.

[Application of RFID system in all aspects of tea products]

Production stage: The producer stores the product name, variety, place of production, batch, pesticide application, producer information and other necessary content in the RFID tag, and uses the RFVID tag to record the initial product information and production process. When purchasing, use the label information to quickly sort the products, and give different purchase prices according to the different conditions of the products.

Processing stage: Use the information in the RFID tag to sort the products. Only products that meet the processing conditions can be allowed to enter the next processing link. For the products that enter the processing link, use the information recorded in the RFID tag to target different products. To ensure the quality of the product, after the processing is completed, the processor will add the processor’s information, processing method, processing date, product grade, shelf life, storage conditions, etc. to the RFID tag.

In the transportation and storage stage: use RFID tags to understand and track the transportation route and time of transportation vehicles with fixed readers installed along the way, install fixed readers at warehouse imports and exports, and automatically record the entry and exit of products. Many agricultural products have higher requirements for storage conditions and storage time. Use the information recorded in the RFID tag to quickly determine whether the product is suitable for storage in a warehouse and how long it can be stored; when leaving the warehouse, choose the priority according to the storage time. The products of the warehouse can avoid economic losses; at the same time, the use of RFID can also realize the rapid inventory of the warehouse, helping the management personnel to know the condition of the products in the warehouse at any time.

In the sales phase: Merchants use RFID tags to understand the status of purchased goods and help merchants implement access management. When collecting money, using RFID tags can confirm the price of customers’ purchases more quickly than using barcodes, and reduce the waiting time for customers. Merchants can write the name of the product, sales time, salesperson and other information into the RFID tag to confirm the product when the customer returns and recalls the product. When there is a problem with the product, because the information of the product’s production, processing, transportation, storage, sales and other links is stored in the RFID tag, the entire process can be traced based on the content of the RFID tag.

【Logistics process】

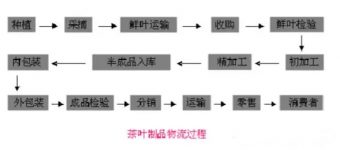

The logistics process of tea products is roughly as shown in the figure below:

【Traceability Control Point】

The system combines the actual needs of the company for product safety traceability, and selects 8 links such as planting, purchase, primary processing, finishing, inner packaging, outer packaging, finished product inspection, and distribution as the traceability control point. The traceability identification of each control point is drawn up, and the product barcode identification is used to encode each traceability identification. By scanning the commodity barcode on the container, label or package of the article, information about the data encoding can be obtained.

【system structure】

This system is divided into three main parts: One: Enterprise product management system. Enterprises can implement standardized identification, recording and query of the information of each traceability control point to realize the information tracking and tracing of the product from planting to sales, so as to achieve the purpose of accurate early warning of product problems in advance and rapid processing afterwards;

Two: Product safety traceability management system. The government supervision department understands the basic status of the production enterprise, product traceability information, raw material sources and product flow;

Three: Data exchange platform system. Sellers inquire about tea products’ planting areas, fertilizers and medicines, production and processing, and quality security inspections.

[ad_2]