Chuangyi Technology RFID Warfare Warehouse Intelligent Management System

[ad_1]

Project Background

In recent years, with the continuous acceleration of our army’s technological process, a modern army has begun to take shape, but compared with developed countries, the army’s logistical support is still relatively backward. Modern warfare is a typical high-expensive war, and the consumption of military materials is unprecedentedly increased. According to our statistics, during the First World War, the average military material consumption of a soldier was 6 kilograms, and during the period in Iraq, this figure had increased to 500 kilograms, and military material consumption increased nearly 100 times. This shows that modern warfare is to a large extent a contest of logistical support capabilities.

The current turbulent international environment and the necessity of a war against Taiwan remind us to be ready for battle at all times. How to establish a complete wartime support system to relieve our army’s worries is a matter for our army. problem. During the Iraq War, the U.S. military’s logistics supplies were tracked throughout the entire process, and all demand chains were clearly visible. All of this originated from the U.S. military’s use of radio frequency identification (RFID) technology. At present, our military supplies support is far from realizing “visualization” in the true sense, which requires us to fill this gap in the shortest possible time. It took the United States 12 years to complete the successful application of RFID. Now that we have experience to learn from, we are ready to use 3 years to achieve the visualization of munitions support.

Therefore, we must prioritize the establishment of a management system for the combat readiness warehouse, and use the application of the system as a starting point to gradually realize the intelligentization of the military’s logistics support.

Traditional warehouse management generally relies on a non-automated paper document-based system to record and track incoming and outgoing goods. The internal management of the warehouse is completely implemented manually, so the efficiency of warehouse management is extremely low. In this regard, Chuangyi Technology uses a warehouse intelligent management system based on RFID radio frequency technology, which can enhance the accuracy and speed of warehouse operations, and reduce the illegal entry and exit and misplacement of the entire combat preparations due to poor management. , Theft, inventory, and shipping errors, etc., and minimize storage costs and ensure the safety of war preparations.

System principle

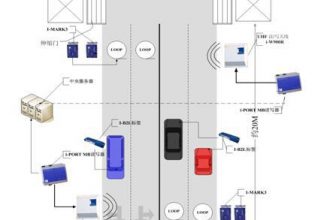

The warehouse management system is mainly used for the automated management of the entry and exit of warehousing supplies, and consists of rfid electronic tags, fixed readers, handheld readers, management center network management equipment and management software installed on the outer boxes of war preparations. When vehicles carrying rfid electronic tags and war equipment materials pass through the radio frequency sensing area set by the warehouse, the system uses rfid electronic tags to realize automated inventory, pick-up, and rapid inventory and material monitoring operations in the warehouse. Through scientific coding, it is also convenient to dynamically manage the batches and origins of items. Using the system’s location management function, it is possible to grasp the current location of all inventory war preparations in time, which is beneficial to ensure the safety of war preparations and improve the efficiency of warehouse management.

Realized functions and achieved effects

◆Real-time monitoring of the storage of war preparations to ensure the safety of war preparations in and out of the warehouse

◆Improve the supervision of war preparation materials, reduce and eliminate the illegal outflow of war preparation materials

◆Real-time combat equipment, vehicle positioning and tracking management

◆High label recognition accuracy, reducing human error input;

◆Increase the accuracy of inventory;

◆Effective inventory management and control, fast and efficient flow of war preparation materials;

◆Efficient use of inventory space, reducing operating costs;

◆The statistical reports of various current and historical affairs of combat preparation materials provide accurate and useful information for decision-makers;

◆The connection of the data exchange interface enhances the management of the existing application system of combat preparation materials;

◆Record the time spent by the material manager to complete the work, grasp the work efficiency of the material manager, and enhance the management of the material manager;

◆After the completion of the war preparation material warehouse management system, it will provide more valuable and time-effective analysis data for the command and decision-making of war preparation materials;

◆Convert a large amount of paper text information required for war preparation materials into electronic data, which simplifies the query steps. Only need to enter the query conditions, the required records will be found, which greatly speeds up the query;

◆Improve the speed and accuracy of data statistics for combat readiness materials, and reduce the difficulty of the work of summary statisticians.

◆Paperless operation reduces paper expenses;

System and product introduction

The system is mainly composed of hardware equipment and software system. The biggest highlight of the hardware equipment is that it is equipped with our company’s latest research and development of active electronic tags, wristband electronic tags, handheld readers, fixed readers, GIM information collection system, warehouse system management software and other components. Military CY-JY-201 electronic nameplate products are suitable for use in the current scientific inventory management system because of their anti-collision, arbitrarily packaging, long service life, and reusable characteristics. Another important equipment is the military CY-JY-205 fixed reader. This product is a high-performance reader produced by our company. The recognition distance of the reader is long and the service life is long. It is a cost-effective product. . The software system is equipped with a warehouse intelligent management system, which can operate and retrieve data at any time and any place, and is equipped with a friendly Chinese interactive interface, which is convenient and quick to use.

Product performance introduction

The military CY-JY-201 electronic nameplate combines the world’s advanced production equipment and mass production craftsmanship. It is a cost-effective electronic label product. This product has high power performance and an identification distance of up to 500-600 meters. A variety of leading technologies in the field of radio frequency and digital technology, using unique software-defined radio technology, micro-power technology, anti-collision technology, response protocol, and locally activated space access technology and other patent portfolios.

Active label product picture

Military CY-JY-205 fixed reader, which can be used online and supports stand-alone operation. Its complete and reliable interface function supports access to all functions of the radio frequency card. The effective recognition distance can reach 1500m, and it can recognize 200 labels at the same time.

.jpg)

Picture of Military CY-JY-205 Fixed Reader

CY-JY-208 Military Handheld Reader

product description

The military handheld reader is a handheld terminal device that integrates RFID and GPRS technology, and is a military-grade PDA. The product integrates voice, video, and data transmission. It is positioned as a professional industrial-grade handheld terminal. It has the characteristics of shock resistance, drop resistance, high and low temperature resistance, and is suitable for various complex and harsh operating environments.

Software part

VC++ is a powerful visual software development tool that has become the first choice for professional programmers to develop software. It is mainly composed of three parts: Developer Studio integrated development environment, MFC, and Platform SDK. SQL Server 2000 is a newer version of the SQL Server database management system launched by Microsoft. Compared with other versions, it has Internet integration, good scalability and availability, enterprise-level database functions, easy installation, deployment and use, and can be used across multiple platforms, so this solution chooses SQL Server 2000 as the back-end database.

① Design and implementation of PDA reader management system

The PDA login interface is shown in Figure 8. The current page displayed on the display interface is the main interface of the system (Figure 9). When you click to select tracking, five options such as “enter”, “write”, “upload”, “download”, and “exit” appear (Figure 10). When “Enter” is selected, the reader first searches for tags near it, displays all tag IDs within the scanning range, selects the corresponding tag ID as needed, and clicks it to read out its contents.

When “Write” is selected, the interface will display a certain fixed format, enter the basic information, and then find the tags within the scan range, and enter the information into the tags you need to enter. If you click “Upload”, the written information will be transmitted to the PC via wireless LAN. If you click “Download”, first connect to the PC via wireless LAN, and then read the information in the PC. If you click “Exit”, the wireless terminal will be automatically exited.

② Design and implementation of PC management system

The reader decodes the read tag information and sends it to the PC for centralized review and processing. Therefore, the system on the PC can be seen as the general dispatch center, which plays an important role. According to the actual application situation, this program adopts the JAVA-based B/S three-tier architecture to develop the PC-side intelligent management system, and conducts real-time and all-round visualized management of its equipment information.

The RFID tag is equipped with a GPS positioning module, so in addition to general functions such as equipment information query, statistics, and analysis, this system also has many new functions such as real-time positioning and tracking of equipment, equipment trajectory viewing, and warehouse location query. For the equipment in task execution, its mobile management is more convenient, accurate and fast. Ensure the safe and timely arrival of equipment dispatching.

[ad_2]