Application case of RFID personnel positioning and attendance system in Baizhuang Coal Mine

[ad_1]

Application background

As the country pays more and more attention to coal mine safety and strengthens its supervision, leaders at all levels pay more and more attention to the working environment and work efficiency of employees. Because the past management software and management technology, especially computer technology, have not been widely used, it has formed The bottleneck of management level.

For this reason, how to correctly handle the relationship between safety and production, safety and efficiency, how to accurately, real-time and quickly perform coal mine safety monitoring functions, effectively manage underground workers, and ensure the efficient operation of emergency rescue and safety rescue is particularly important and urgent. Facing the new situation, new opportunities and new challenges, the leaders of the national competent departments at all levels put forward high requirements and expectations for work safety. We believe that improving the level of information management of production safety and strengthening the long-term safety production mechanism with disaster prevention and search and rescue as the main goals are the only way for my country’s production safety work. In view of this, under the leadership of the group company, our mine cooperated with Shanghai Bosoft Electromechanical Co., Ltd. to install the KJ249 type mine personnel underground personnel attendance positioning system.

1. The principle and goal of selecting the installer to locate the attendance system

1. Design and installation principles

⑴ Realize the current positioning and attendance requirements of the underground workers in our mine, and the system is scalable

⑵ All identification equipment is based on the existing computer LAN construction to ensure that the system will not be eliminated within ten years

⑶ The design of underground personnel positioning and attendance system should realize the functions of query and printing of various departments

⑷ Real-time tracking of specific personnel can be carried out;

⑸ The current identification records of underground personnel positioning and attendance can be stored in the database in real time;

⑹ Equipped with UPS power supply to ensure that underground equipment and ground servers can run for at least 2 hours when the mine is out of power for maintenance;

⑺ The system has the ability to cope with network paralysis and server failure, and all underground personnel positioning equipment has the ability to operate independently.

2. Design and installation goals

⑴ Use advanced standardized network equipment to realize comprehensive, accurate and real-time underground positioning management requirements for personnel;

⑵ The terminal equipment is directly connected to the mine LAN, making the entire system based on the advanced network structure to achieve more management, query, and maintenance functions;

⑶ When the network is disconnected, the underground positioning terminal can be operated as a stand-alone unit, and the underground positioning record can be automatically uploaded after the network is restored;

⑷ The entire management system includes application modules such as underground positioning management, attendance management, employee file building, record query, report summary, etc., which can provide comprehensive management and services for the mine in daily management such as employee attendance and underground personnel positioning.

⑸ The underground positioning software allows centralized authorization and decentralized management;

⑹ With a flexible and comprehensive report system, users can customize the report format, which is suitable for various needs;

⑺ There is a separate report to show the detailed information of the personnel who go down the well, the time of going down, and the time of going up the well. Real-time automatic statistics of the detailed information of the underground personnel and the daily and monthly reports of the underground personnel. In the event of an accident, the number and data of the personnel who have not been on the well can be displayed in real time.

After careful analysis and research by the group company and mine leaders, it was decided to select the KJ249 type mine personnel attendance and location system for underground personnel of Shanghai Bosoft Electromechanical Co., Ltd. The system is advanced in technology, reasonable in design, novel in structure, main technical performance indicators meet the safety standards and requirements of the downhole industry, stable performance, reliable quality, and simple operation, which contribute to improving the safety and effectiveness of the modern downhole working environment Outstanding contribution. The system conducts real-time monitoring of personnel entering the well, and can check the number of people downhole at any time. In the event of a catastrophe, the situation of the personnel at the accident site can be immediately checked from the monitoring computer, and the number of trapped people can be displayed in the software, providing a scientific basis for accident rescue. The successful launch of this system will certainly play a positive role in the safety production of coal mines in our country and the rescue and disaster relief after accidents.

2. Overview of KJ249 Personnel Positioning and Attendance System

KJ249 mine personnel underground personnel attendance and location system integrates high-tech radio frequency identification technology, adopts dual-frequency point long and short wave frequency to realize reliable full-duplex wireless data communication, substation equipment, control equipment, communication interface and RFID identification The card adopts an explosion-proof and intrinsically safe design, has a long operating distance, can adjust the recognition range of the system arbitrarily, recognizes no “blind spots”, strong signal penetration, high security and confidentiality, no electromagnetic pollution to the human body, and strong environmental adaptability , It can identify multiple people at the same time, and is convenient for underground network connection and digital transmission. At present, this new information collection, storage, transmission and processing technology will be very important for the monitoring, control, monitoring and tracking management of underground personnel in coal mines. The role of.

The KJ249 mine personnel underground personnel attendance and positioning system realizes that the underground personnel and equipment positioning system can timely and accurately reflect the dynamic conditions of personnel and equipment in various areas of the underground to the ground computer system, so that the managers can grasp the distribution of underground personnel and equipment at any time The status and the movement trajectory of each miner to facilitate more reasonable scheduling management. When an accident occurs, rescuers can also quickly understand the location of relevant personnel based on the data and graphics provided by the underground personnel and equipment positioning system, and take corresponding rescue measures in time to improve the efficiency of emergency rescue work. At the same time, the underground mine personnel attendance and location system is a database application system that integrates personnel management, underground location management, and underground attendance management functions. Powerful and easy to use, it is suitable for underground positioning management of coal mine enterprises. The system application software realizes the downhole positioning data management, reports, and downhole positioning communication, etc.; the software provides the communication function with the downhole positioning equipment, and the downhole positioning equipment can be remotely monitored through the software; the software also sets the user authority and the system administrator You can add/delete users and assign permissions at any time. Users with different permissions are allowed to use different functions, which not only facilitates the management of users, but also ensures the reliability and safety of the system.

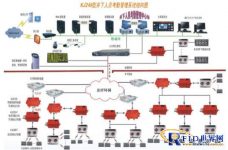

3. The working principle and system structure diagram of KJ249 personnel positioning and attendance system

working principle

The KJ249-F dynamic target recognizer transmits the encrypted data carrier signal at any time through the transmitting antenna integrated on the circuit board; the KJ249-K personnel identification card carried by the personnel enters the working area of the KJ249-F dynamic target recognizer and is activated ( The identification card is in a dormant state and does not work if it does not enter the working area of the transmitting antenna), the personnel information is sent to the KJ249-F dynamic target recognizer through the anti-algorithm integrated with the KJ249-K personnel identification card, and the KJ249-F dynamic target recognizer receives After the information sent to the KJ249-K personnel identification card is processed, it will either be sent to the card reading substation and then sent to the ground central station by the card reading substation, or sent directly to the ground central station by the KJ249-F dynamic target recognizer to complete the mine. Personnel automatic tracking and positioning management.

4. Features and composition of KJ249 personnel attendance positioning system

System Features

1. The equipment has strong adaptability and unimpeded passage: it can conduct non-contact information collection on long-distance moving targets in coal mine roadways, with identification without “blind areas”, strong signal penetration, high security and confidentiality, and no electromagnetic pollution to the human body. The environment is adaptable, multiple people can be identified at the same time, and there are no restrictions on the way of passing. Multiple people are allowed to pass in “groups” and “groups” without any operation during the passage, which does not affect the normal passage of underground personnel. Operation.

2. Simple structure, strong scalability, and easy maintenance: The system adopts a four-level mode, and the dynamic target recognizer can be flexibly configured according to user needs, and can be expanded at any time with the development progress. The more substations and dynamic target recognizers are configured, the more positioning areas will be, and the more accurate the location of personnel will be. The equipment adopts modular design to facilitate management and maintenance.

3. Equipment can be reused, reducing investment: The system can be shared with the safety production monitoring system. Various types of sensors can also be added to the system to form a multi-functional integrated monitoring system.

The composition of the system

The KJ249 mine personnel management system is divided into two parts: surface and underground:

Ground part-personnel information collection and processing center, also known as monitoring center station. It is mainly composed of communication interface, dedicated personnel monitoring and management software and monitoring host, ring network access device, printer, monitor, lightning arrester, etc.

The underground part uses personnel positioning sub-station, dynamic target recognizer, personnel information card, mine power supply box, and main unit of power cut-off device as the basic unit of wireless detection and processing of underground personnel code information. In areas where the monitoring points are relatively concentrated, the connection method of mine intrinsically safe power supply + personnel positioning substation + dynamic target recognizer can be adopted; for relatively scattered monitoring points, the method of dynamic target recognizer + power-off device host can be used directly to form a network. Convenient and flexible.

The underground mine is connected by a two-core mine signal cable to complete the two-way real-time communication task between the monitoring host and the underground personnel positioning substation or the dynamic target recognizer. At the same time, it can be connected to the existing coal mine safety monitoring system.

1. Main technical indicators of the system

System capacity: 64 substations or directly connected to 64 KJ249-F dynamic target recognizers

Each substation can be connected to dynamic target recognizers: 8

Number of management employees: 65,535

Substation communication mode: RS485, DPSK or optical fiber

Communication distance: more than 15Km

Maximum system inspection cycle: less than 26s

Processing content: coal mine personnel attendance and location management

Network platform: Ethernet

Operating system: WIN XP/2000/2003

Database: SQL SERVER 2000

2. Monitoring host: Responsible for the management of the entire system equipment and personnel detection data, sub-station real-time data communication, statistical storage, screen display, query printing, screen editing, network communication and other tasks.

3. Transmission platform: supports various communication modes, including Ethernet composed of optical fiber and cable, industrial bus, etc.

4. KDW220 (A) explosion-proof and intrinsically safe power supply box and KJ220-F information transmission substation: through wired communication with each dynamic target recognizer, real-time personnel code data (can be displayed locally).

Input voltage: 127/220/380/660VAC

Transmission rate with dynamic target recognizer: 2400bps

Transmission rate between ground center station: 2400bps

The number of dynamic target recognizers that can be connected to the substation: ≤8

Transmission distance: the distance to the dynamic target recognizer: adjustable within 2 kilometers (MHYVRP cable); the distance to the 1000M optical fiber backbone network switch: within 100 meters;

Power supply type: mine-use explosion-proof and intrinsically safe uninterruptible power supply, under the condition of full load, the power supply time is not less than 2 hours.

5. KJ249-K personnel information identification card: the personnel who go down the well shall be installed and worn on the safety helmet.

KJ220-J data transmission interface

Explosion-proof mark:[Exib]I

Safety sign number: 200613373

Explosion-proof certificate number: 1045585G

Working voltage: 3.3V~3.6V;

Working frequency: 2.40±0.08GHz;

Maximum wireless transmission distance: 50m underground.

Protection level: IP54 (waterproof, moisture-proof, coal dustproof)

6. KJ249-F dynamic target recognizer:

KJ249-F dynamic target recognizer (hereinafter referred to as “recognizer”) is used to track personnel information in coal mines and realize communication with wireless identification cards. Receiving the wireless personnel code signal sent by the identification card, it can scroll the monitored identification card numbers on the spot, dynamically store all the identification card numbers monitored within 24 hours, have the “black box” function, and have the sound and light alarm function.

The recognizer is allowed to be installed in a dangerous gas environment with coal dust and gas explosion in the coal mine.

Explosion-proof type: intrinsically safe

Explosion-proof grade: ExibI

Associated equipment: KDW220 (B) type explosion-proof and intrinsically safe power supply box:

Explosion-proof type: mine explosion-proof and intrinsically safe type

Safety mark number: 20069697

Explosion-proof certificate number: 1062564

Matching equipment: YHT1 universal remote control:

Explosion-proof type: Intrinsic safety type for mining

Explosion-proof mark: ExibI

Working voltage: 18V; Working current: ≤90mA

Communication with information transmission substation: communication method: RS485; transmission rate: 2400bps;

Maximum transmission distance to the interface: 15 km; (MHYVRP cable);

Communication with identification card: working frequency: 2.40±0.08GHz;

Maximum wireless transmission distance: 80m underground.

Recognizer adaptation conditions:

1) Ambient temperature: 0℃~+40℃;

2) Average relative humidity: ≤ 95 (+25℃);

3) Atmospheric pressure: 80kPa~110 kPa;

4) Places without significant vibration and impact;

5) Underground coal mines, places with explosive mixtures of gas or coal dust.

The communication between the recognizer and the host computer:

1) Communication method: RS485

2) Working mode: master-slave half-duplex

3) Transmission method: Wired transmission transmission rate: 2400bit/s

4) The maximum transmission distance to the interface: 1.5 km; (MHYVRP cable, cross-sectional area: 1.5mm2, cable distribution parameters: distributed capacitance: ≤0.06μF/km; distributed inductance: ≤0.8mH/km; DC resistance: ≤12.8Ω /km); Communication between the recognizer and the recognition card:

1) Modulation method: FM

2) Transmission mode: wireless same frequency asynchronous half duplex

3) Operating frequency: 2.40±0.08GHz

4) Receiving sensitivity: ≤-65dBm

5) Transmitting field strength: ≥-40dBm

6) Simultaneous recognition ability: 100

7) Maximum transmission distance: adjustable within 50m

8) Storage capacity: 640

5. Introduction to KJ249 personnel positioning and attendance system software and main functions

The KJ249 downhole personnel attendance and positioning system mainly includes several menu function modules such as files, moving target detection, attendance statistics, simulation chart setting, moving target management, data maintenance, comprehensive setting, user information, help and so on. The system can record staff card number information, can identify active ID cards, read card numbers, sound and light prompts, data record storage and processing, and has a networked communication function for underground staff attendance and tracking management system.

The underground personnel positioning system is supported by the main computer of the mine ground monitoring center and the software database through the transmission interface and the communication optical cable laid in the roadway to track the underground employees in real time. The data information is processed by the software and converted into digital signals, so that the underground The dynamic distribution of personnel or the environmental safety status can be reflected in the main computer in real time, so as to realize the purpose of digital management of the underground safety status on the well.

Main functions of the system

1. Real-time positioning and tracking query of dynamic targets: It can track and return the movement information of personnel in real time, query the dynamic distribution and quantity of underground personnel, and query the current location of any underground personnel, the location and situation at a specified time, And for real-time tracking display.

2. Personnel tracking function: It is the core function of the positioning part of this system. This function can track the current underground position of a specific person in real time, the place and time of the day to work, the detention time at each position, and its running track Perform visual and intuitive playback on the roadway distribution map. This function can quickly locate specific personnel, check whether relevant leaders have performed follow-up work and supervise special types of work. For the loss and damage of property in a specific location underground, the responsible person can be delineated.

3. Query statistics: including downhole employee query, employee distribution query, downhole population statistics, regional population statistics, unreached area query, overtime employee query, number of people going up and down the well, substation information query, substation abnormal query, and personnel history track query And various data report printing.

4. Attendance management function: it can automatically count the time of going and going down the well to effectively prevent the phenomenon of early rise; it can reflect the flow route and location of the downhole personnel in real time, and effectively supervise the personnel in safe production positions such as tile inspectors and security inspectors; Effectively improve the ability to prevent production safety, effectively reduce the “three violations”, and promote safe production.

5. Rescue function: When a disaster occurs, it can display real-time data such as the number, identity, and location of the people in the disaster area, so as to provide accurate decision-making basis for emergency rescue and disaster relief.

6. Networking function: The software provides multi-client query function, which can be monitored by a computer connected to the automation platform network, and provides an OPC interface, which can exchange data with OPC client software.

7. Safety monitoring management: track the movement trajectory of individual operators in the well, and record their stay time in each area and each monitoring point.

8. Loss of alarm: If it is found that personnel are working overtime in the well, the system will automatically alarm and give a list of relevant personnel and other information.

9. Emergency handling: When an emergency occurs, you can query the information of personnel near the accident site, and provide commanders with information on the distribution of personnel in various areas of the mine. When an emergency occurs and the system communication cannot be restored, it can provide the commander with the latest (30s before) historical distribution information of the personnel in each area of the underground to help the commander formulate an emergency plan.

10. System operation management: real-time monitoring and recording of system communication and system equipment working conditions, and alarms for system abnormalities.

11. Authority management: Different authority can be set, and only professional managers are allowed to perform various permitted authority operations, non-professional managers are only allowed to browse, and people who are not in the department have no right to enter the system. It has the function of setting network node authority, which can restrict the operation authority of different node operating stations.

12. Management settings: It is dedicated to maintain the personnel structure and organizational structure of the mine, and provide basic information for attendance and positioning functions. Management items include: department management, job management, title management, work management, mining management, shift setting, allowance management.

13. Safety management: monitor some special personnel, inspection personnel, inspection personnel, etc., understand their actual operations, strengthen their responsibilities, and reduce the possibility of accidents; supervise and inspect the main team leaders in the mining area, The actual follow-up situation of the business department strengthens the on-site management of the entire mining area.

14. The unique management of personnel entering and exiting the well: through the corresponding management display of the number of personnel entering and exiting the well and the identification card and the personal image data of the personnel, it is possible to query the personnel who enter and exit the well for more than the specified time.

15. Mine image management: According to the distribution of existing mine roadways, draw a schematic diagram of the mine roadway distribution, and check attendance and locate the sub-station location icon on the upper position.

16. Department personnel information management: realize the entry of mine staff information, and set the corresponding relationship between the personnel number and the identification card number.

17. Hardware information management: It mainly manages the name and hardware code of the attendance positioning sub-station, and enters the identification card information.

6. Application and experience of KJ249 personnel positioning and attendance system in our mine

Our mine installed the KJ249 mine personnel attendance positioning system in June 2008. The use of this system has greatly increased our mine’s management of underground employees, mainly in attendance rate and employee safety management. After the system runs, when the cardholder enters the radiation area of the substation, the identification card is activated, and the identification card transmits the card number back to the substation and records it in the substation memory.Several positioning sub-stations transfer the personnel movement information collected from various places to the computer system through communication optical cables, modems, switches, network cables and other equipment. Managers use the KJ249 mine personnel positioning and attendance system to query the distribution, attendance, and working hours of underground personnel. condition

1. The application of personnel positioning and attendance system, the attention of the leaders, and the promotion of the government are the key. Since 2000, our mine has attached great importance to and started to promote the construction of a new type of coal industry. It has taken the lead in establishing a “digital” monitoring and control system for coal mine safety production in coal mines across the province and even across the country. The government strictly stipulates that the construction of an attendance and positioning system for underground personnel in coal mines should be used as an important basis for assessing the annual work of the person in charge of the unit. For coal mines that cannot complete the task within the time limit, the responsibility of the mine manager of the township coal mine should be strictly held. The attention of the leaders and the promotion of the government have provided a strong organizational guarantee for our mine to successfully complete the construction of the underground personnel attendance and positioning system.

2. The application of personnel positioning and attendance system must be aware of the position and effective measures. The fundamental difference between the establishment of the gas monitoring and monitoring system and the present installation of the mine personnel attendance positioning system is that the former is mainly for monitoring and monitoring gas and effectively preventing the occurrence of gas accidents, while the latter is also for coal mine safety production, but because it involves coal mines. The “sensitive” issue of the number of people entering the well, most people tend to feel resistance at first. In order to solve the problem ideologically, in addition to holding mobilization meetings, our mine also held seminars and seminars in segments and at different levels, and some even communicated individually. With tireless and reasonable explanations, the resistance gradually disappeared, and more and more voices were in favor, and the construction of the underground coal mine personnel attendance and positioning system was guaranteed.

On this basis, we have adopted four measures to promote it. The first is the responsibility to the person. Implemented the responsibility system for the staff of the department to pack the film and the area, and formulated clear rewards and punishments. The second is step by step. It means scheduling progress in batches and in installments, and set deadlines. The third is timely guidance. In order to ensure that the trial operation of the system is completed on schedule, the mine leaders formed an inspection and supervision team to provide timely guidance. The fourth is to attach importance to coordination. Instructed a deputy deputy department-level leader to be responsible for coordinating the relationship with the manufacturer, solving various contradictions and problems in a timely manner, and promoting the smooth progress of the installation work. Up to now, all locations at the -150, -250, and -430 levels of the mine are connected to the monitoring center of the dispatching room. Successfully realized the accurate scheduling and attendance of underground personnel.

3. The application of personnel positioning and attendance system, emphasizing practical results, and working hard on the word “management”, has realized the construction of a new type of coal industry.

Baizhuang Coal Mine has deeply realized in the process of building a new type of coal industry for many years that to make new technologies and new equipment really work, it is necessary to make great efforts in management. To this end, our mine has adopted four measures. One is to improve the system. On the basis of the original monitoring and control management system, the “Baizhuang Coal Mine Underground Personnel Positioning Monitoring and Management System Real-time Data Format Specifications and Requirements”, “Baizhuang Coal Mine Underground All Personnel Identification Card Use Management Measures” and “Baizhuang Coal Mine” Management systems such as the Operation Ledger of the Attendance and Positioning System for Underground Personnel in Coal Mines. The second is to strengthen training. All monitoring and management personnel of the mine shall receive special training in phases, and can only take up their posts after being qualified. The third is strict inspection. It is to take the operation and use of the underground personnel attendance and positioning system as a main content of the safety inspection. The monitoring and maintenance workers must check the operation of the system and fill in the inspection card when they go down the well. The fourth is serious investigation and punishment. Regarding the failure of the personnel attendance positioning system as a major safety hazard, it is clearly stipulated that the relevant responsible persons shall be investigated and dealt with seriously.

By taking the above measures, the Baizhuang Coal Mine’s underground personnel attendance and positioning system has demonstrated its superiority in seven aspects during the trial operation. First, it can effectively control the number of people entering the well. Second, it can effectively control overtime production. Third, the monitoring system can at any time inquire about the action trajectory of the personnel of special types of work underground and the leaders of the attendants, which is conducive to promoting the due diligence of special personnel. Fourth, it is conducive to the internal attendance management of the enterprise. Fifth, it is conducive to restrict workers from entering prohibited areas such as blind alleys and goafs. Sixth, mine leaders can check the number and distribution of the number of people underground on the monitoring system at any time, which is conducive to improving the level of coal mine safety supervision. Seventh, the historical data of the monitoring system can be stored for more than one year, and there is a “black box” in the investigation and handling of coal mine safety production accidents.

Baizhuang Coal Mine has gained experience and benefits in actively applying the KJ249 mine personnel positioning and attendance system to promote the new construction of the coal industry. The installation and operation of the mine personnel positioning system has pushed human management to a higher level. The system can realize functions such as accurate positioning of underground areas, replay of employee activity trajectory, employee attendance, and work statistics. It not only provides new management methods for managers at all levels, but also provides new ideas for the formulation of reward and punishment systems, which greatly strengthens the management of safety production and the depth of humanized management.

About the author: Zhao Shuhua, male, Han nationality, born in June 1961, graduated from Shandong University of Science and Technology in 2007, and is currently the mine manager and senior engineer of Baizhuang Mine of Feicheng Mining Group Company.

[ad_2]