Dazhong Mining deploys a full-staff production and maintenance system based on Xerafy industrial RFID tags

[ad_1]

Dazhong Mining deployed Xerafy industrial RFID tags and mobile handheld readers to track equipment availability and operation and maintenance records on the job site.

The company specializes in iron ore and has production bases in Inner Mongolia and Anhui provinces. Improving operational efficiency through TPM (full-staff production and maintenance system) The availability of equipment is critical to operational efficiency.

In September 2020, Dazhong Company launched a new asset management system based on TnPM (Full Staff “Standardized” Production Maintenance), which is an extension of the Total Staff Production Maintenance (TPM) popular in China.

Mining equipment of Dazhong Mining © Dazhong Mining

As a way of tangible asset management, the goal of TPM strategy is to improve the overall availability of equipment and machinery through proactive and preventive asset maintenance.

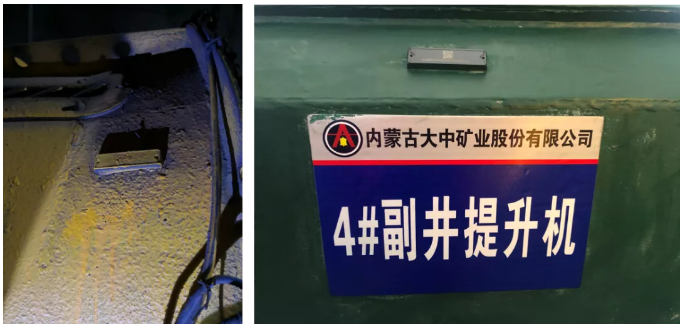

Extraction equipment of Dazhong Mining © Xerafy

Complex operation

The extraction and transformation of iron ore involves complex work processes and various mechanical equipment.

Iron ore © Dazhong Mine

Iron ore is an important raw material for steel production. Its extraction and transformation involve multiple processes, including crushing, grinding, magnetic separation, flotation and gravity separation. Dazhong Mining also provides iron pellets mainly used for blast furnace ironmaking and iron ore concentrate iron powder used for iron and steel smelting.

Job site © Xerafy

The equipment and machinery used by the company’s mining site in Inner Mongolia are distributed over a wide area. The mining area covers an area of 20 square kilometers, equivalent to 1/3 of the area of Manhattan. The mine consists of 4 mines, with an annual ore mining volume of 1.8 million tons. The typical operating environment of the mine makes the operation more complicated: more than 900 employees work in shifts 24 hours a day, working underground at a depth of more than 900 meters.

Dazhong Mining Inner Mongolia mining area surface and underground environment © Xerafy

Safety and operational requirements Dazhong Mining needs to conduct an annual inventory of all the assets of the mine every year, all production equipment is inspected quarterly, and certain critical equipment related to safety is inspected daily. The large scale and area of the mining area makes manual inventory difficult and time-consuming. A large inventory takes about 2 months to complete each year. Inventory personnel need to carry a thick paper checklist to check each asset one by one from the ground to the underground. Each record is updated on paper, and then the data is manually entered into the company system. Repeated work can easily lead to human error and missing information.

Paper asset list for manual inventory © Xerafy

Dazhong Mining realized that it needed a new method to accurately and effectively manage assets to achieve the goals of TPM. Dazhong Mining has been looking for an RFID system to provide data for its computer maintenance management system (CMMS). Xerafy recommended Cargo Trak II, an industrial RFID tag.

Xerafy Cargo Trak II installed in mining equipment © Xerafy

Xerafy Cargo Trak II is a tag in the Outdoor Trak series. This series of RFID tags is specially designed for field operations. Each UHF RFID tag has a unique identification number, IP68 waterproof housing, metal surface reading range up to 12 meters, (non-metallic up to 6 meters), it is an ideal choice for ground and underground asset tracking. The label can be used on metal and non-metal surfaces, providing a universal label solution for various mining equipment and machinery. The rivet hole of the label can realize a firm installation method, and can provide the option of adhesive and cable tie installation. Tian Gong, who tracks on-site assets and is responsible for equipment management, told us: “In the past, it usually took about 2 weeks to find, identify and record 272 on-site assets. After using the RFID system, it can be completed in less than 1 week, saving 50% of the cost. Time, while ensuring the completeness and accuracy of the data.”

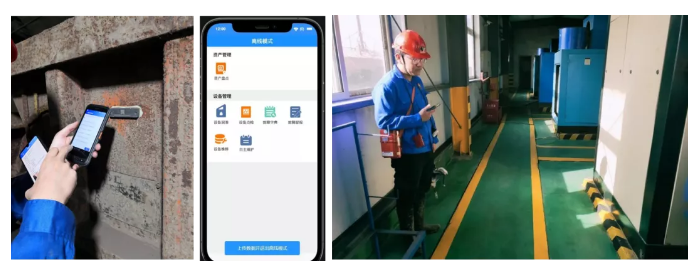

PDA with RFID function is used for automatic inspection of mining equipment © Xerafy

Now, on-site inventory is carried out using a mobile PDA with RFID function. The PDA is equipped with an asset inventory app. Even in the wells with insufficient light, equipment data can be obtained in batches from a long distance.

Xerafy Cargo Trak II installed on fixed assets © Xerafy

Through the successful deployment of two mines in Inner Mongolia and Anhui, Dazhong Mining plans to expand its asset management solutions to the field of fixed assets and office equipment management to further improve the operational efficiency of the company.

[ad_2]