RFID container management technology will make port transportation bigger

[ad_1]

Due to the rapid economic development, logistics has become the basic construction of economic development. The transportation volume of containers is increasing. How to conduct scientific and effective management? RFID container management technology will be used. Since RFID has a great advantage in the field of automatic identification, the application of RFID technology and containers will greatly improve the transportation management of containers. efficient. In the past, container management was mainly achieved through information management systems combined with manual non-real-time manual data entry. Some advanced management systems adopted image recognition technology and used cameras to identify container numbers. These traditional methods of tracking, managing and dispatching containers have problems such as low efficiency, high labor costs, high error rates, and poor real-time performance. Electronic tag (RFID) technology has been tentatively applied to container management and achieved good results.

However, RFID uses passive transmission technology, which is very dependent on personnel in the data collection process, and it has not been able to solve the problems of real-time collection of container information in the yard.

Using sensor technology combined with RFID technology, a container management system for the Internet of Things is proposed.

1. Introduction to Container Management

Container management can be divided into two parts:

(1) The use and dispatch management of containers, including the management of container business information such as container distribution, dispatch, lease start, lease withdrawal, insurance, repair, and loss reporting;

(2) The management of container status information, including container location information, classification information, and cargo information in the container.

For non-real-time information, relatively mature container management software is currently available. For a lot of information in Part 2, in most cases, it can be solved by increasing a lot of labor costs. The application of the sensor network proposed here is mainly designed for the second part, which can effectively improve the efficiency of container information collection and management.

2. Container management system structure

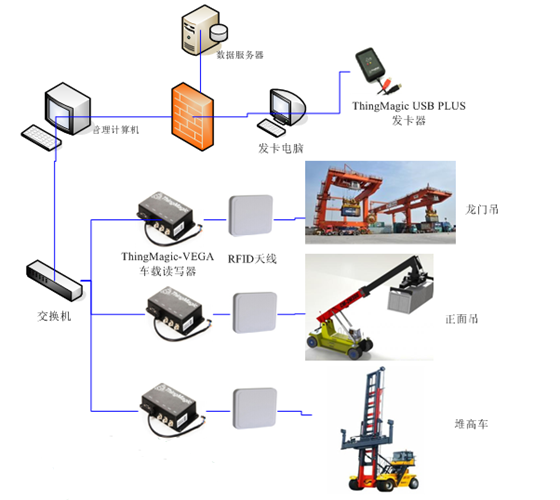

The wireless local area network real-time positioning system combines multiple technologies such as wireless local area network, radio frequency identification (RFID) and sensors to realize complex container monitoring and tracking tasks and accurately find the target object in a wide range of wireless local area network coverage.

3. System realization principle

There are multiple rectangular container stacking areas in the container yard. Each area can arrange 4 to 6 boxes side by side. Each row can stack 4 to 6 layers. The entire yard is covered by a 2.4GHz wireless network.

The sensor nodes are designed into 3 categories according to the specific conditions of the yard:

The first type of node is a node placed in the container body, responsible for sending container information;

The second type of node is a node deployed on the crane frame, which is responsible for collecting container information and can sense the signal strength sent by the first type of node;

The third type of node is a node placed in the crane control room. This node is responsible for collecting the information of the second type of node, and is connected to the wireless network, and sends the collected information to the general control room. Each stacking area is responsible for 1 type 3 node.

4. Use GPS technology to realize container positioning management

The system uses a sensor network to determine the location of the container. In order to achieve the purpose of positioning, assume two facts as the premise:

(1) The location information of the container stacking area in the yard is known;

(2) All containers stacked in the stacking area are operated and only completed by the container cranes in the stacking area.

In this way, the GPS device on the crane can be used to determine the position of the crane first, and then the position information of the container that the crane is operating can be obtained. Since all container operations in the stacking area are completed by the crane, once the operation of the crane is obtained The position information of the container can obtain the change information of the position of all the containers in the stacking area, so as to determine the position of each container.

In the system, the core RFID data collection equipment will be installed in mechanical equipment such as gantry cranes, reach stackers and stackers. In the application of this type of equipment, RFID readers should have basic data collection functions as well The standards for the use of on-board equipment have high requirements for high and low temperature, electromagnetic compatibility, low frequency vibration, impact, etc., and the working environment is mostly outdoors, and the environmental conditions are also relatively harsh, which raises higher requirements for the selection of the entire RFID reader Challenge.

[ad_2]