Application of RFID technology in container transportation in Kaohsiung Port, Taiwan

[ad_1]

Case background

Taiwan’s economy is centered on trade. 99% of imported and exported goods are transported by containers. Some containers must be transported via urban roads or temporarily stored in inland container yards during re-export procedures. This is prone to control risks. The customs is to prevent re-export containers. Smuggled and smuggled during transportation, manual escort has been used for many years, which not only increases manpower and shipping costs, but also causes a lot of inconvenience to related businesses.

Among them, Kaohsiung Port is quite representative as Taiwan’s largest port. There are five container centers in the entire port area. When the re-export container is unloaded for import or shipped out of the ship, it must be transported out of the port police to check the registration station, and then transported from the taxation area to the five container centers. Before the introduction of EPC / RFID applications, its container dynamic checking system automatically executes the deposit. There are more than 1.2 million re-export containers staying at Kaohsiung Port each year, of which 40,000-50,000 containers must be selected for inspection. The transportation company applies to the customs for escort transportation. The escort costs are borne by the shipping company. At the same time, one container is escorted. The time and manpower consumed are also considerable. The transshipment time is very long, up to 4-10 hours. The Kaohsiung Port Authority strictly controls the time of container entry and exit in a drip-proof manner. The purpose is to reduce the occurrence of illegal smuggling, which undoubtedly increases the customs. The workload of the personnel. The specific questions are as follows:

About 20,000 container trucks of the 10 major airlines pass through 5 container centers and the urban area every day. Security monitoring is critical

10 million containers enter and exit the port in Kaohsiung Port every year, and about 50% are re-export containers

Every year, the customs will draw 5% of the re-export containers for manual escort, which affects the operating efficiency of the airlines and increases the operating costs

In view of the successful international application of RFID technology into the freight operation process and the improvement of the efficiency of transshipment container handling, various departments in Taiwan have actively promoted the “Kaohsiung Port Transit Container Escort Plan”, replacing manual escort with EPC/RFID technology facilities, and building “electronic seals” surveillance system”.

case analysis

In response to international development trends, the design of container seals has evolved from traditional mechanical seals to electronic seals (electronic seals). The idea of electronic seals originated from the addition of RFID tags to the design of mechanical seals. The two combined into one is the so-called electronic seal electronic seal label. At present, whether it is active or passive electronic tags in the world, the mechanical seal part adopted in the world all follows the standard of the standard 17712 seal mechanical lock. The difference between an electronic seal and a traditional mechanical seal is that the chip in the seal contains a memory that can record relevant container information, and once the passive electronic seal is unlocked, it is destroyed and cannot be sealed and read. Therefore, the electronic seal can be used to seal the container, which can completely record the container transportation information between the starting point and the destination, point and point, and the safety of the electronic seal means that the container has arrived safely without being damaged in the middle. Containers can be monitored, located, confirmed, and even analyzed the transportation status in the global supply chain. These data are collected, stored and shared through the network of RFID technology. In addition, it also contributes to the trend of automated development of verification procedures in the supply chain. In the green channel customs clearance, electronic seals can be used to simplify inspection procedures.

In order to be in line with international standards and solve the problem of insufficient manpower in the escort of re-export containers, the customs decided to replace manual escorts with EPC/RFID applications, and use the combination of ISO17712 mechanical seal locks and EPC second-generation tags to form passive electronic seals, which are installed before container shipments. It is a one-time-use seal lock. Regardless of the different roles in the supply chain and the stay at multiple locations, the integrity of the container can be immediately determined when the container is unloaded, and the carrier can complete the delivery procedures to complete the business.

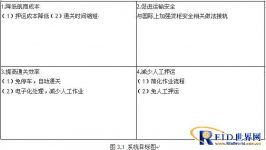

The system goals for implementing the Internet of Things based on RFID technology are shown in Figure 3.1:

1. Reduce carrier costs

(1) Reduced cost of escort transportation (2) Reduced customs clearance time

2. Promote transportation safety

Integrate with international practices related to strengthening container safety

3. Improve the efficiency of customs clearance

(1) No parking, automatic customs clearance

(2) Electronic processing, reduce manual work 4. Reduce manual escort

(1) Simplify the operation process

(2) Free of manual escort

solution

Using long-distance UHF RFID technology combined with image recognition and customs declaration database, the mobile security detection and management of 20 automated lanes in Kaohsiung Port and the transit container trucks of 10 airlines are carried out.

Important nodes related to containers in the port are storage and transportation centers, container yards, terminal frontiers, and customs. These important nodes should work together to pilot the implementation of electronic container management, forming a collaborative management of container information within the region. For example, a set of RFID readers are set up in the container storage and transportation center. When the container with electronic tags leaves the field, the REID reader will transmit the read container information to the server on site through the network communication system.

Two sets of RFID readers are set up in the container yard, which are the control RFID arrival readers and the RFID monitoring readers in the yard. The RFID approach reader installed in the port control center actively reads the arrival information of containers equipped with electronic tags. The RFID monitoring reader on the site can cooperate with the straddle carrier to implement security monitoring of the containers in the yard. Set up a reader at the customs bayonet. The bayonet host reads the data of the electronic license plate, driver’s card, front box electronic box number label, and rear box electronic lock data for the container equipped with electronic tags; weight data is obtained through the electronic platform scale ; Obtain container image information through the container number recognition module and identify the container number. These data are transmitted to the customs logistics monitoring platform by the bayonet host through the network. The implementation of electronic container management within the scope of the port can improve the accuracy and convenience of container logistics information collection, and improve the efficiency of customs clearance; provide powerful conditions for improving the automation level of port operations; and also improve the informatization and transparency of the container logistics supply chain Provides the foundation. The following is the information flow chart and business flow chart of the system:

Evaluation

System characteristics

The real-time monitoring function can remotely monitor the working conditions of various checkpoints in real time.

On the premise of maintaining the security and anti-counterfeiting of RFID with a globally unique identification code, the use of the second-generation EPC specification can not only reduce subsequent procurement costs, but also is beneficial to international standards and has substantial benefits for airlines in reducing global operating costs.

The magnetic induction trigger system is used to replace the infrared system, which is less affected by the weather, suitable for the environment of Kaohsiung Port, and further improves the reliability of the system.

The installation position of the RFID tag does not affect the reading result of the system.

The 40-foot trailer is loaded with 2 containers in the front and rear, and the test reading rate reaches 100%.

Preliminary benefits of the system

The average reading rate is 97.42% (reading distance is more than 7 meters), fully automated and high-security operations, the rate of container smuggling is significantly reduced, and the safety of container transportation is improved.

Each year, it can save about 3,300 hours of customs clearance time and more than 10 million yuan in escort freight, which reduces the cost of airlines.

It can save about 10,000 escort manpower every year and improve customs administration efficiency and service quality.

The customs clearance process of escort containers is reduced, and each vehicle is shortened by about 0.8 days on average, which improves the competitiveness of Kaohsiung Port.

With passive RFID electronic seals, which are the only chip code in the world that cannot be forged, they can be read by RFID handhelds and pass through the automated lanes of the port area when container trucks are not stopped. The fixed type has been installed at the gate. The RFID technology reader reads and automatically recognizes, and achieves the benefits of automatic safe escort. Once the passive RFID electronic seal of the container truck is damaged or not sealed or cut, it cannot be read. It is a highly safe container transportation escort method , In line with the development trend of global container transportation. Therefore, it is not only conducive to the management of container transportation, but also provides security and tracking functions, and has an anti-counterfeiting mechanism, which greatly reduces human manipulation errors.

in conclusion

RFID technology, sensor technology, etc., as the foundation of the Internet of Things, have a wide range of applications in the transportation industry, mainly including the e-government field, the intelligent transportation field, and the transportation/logistics field. Automatic identification of container vehicles entering and exiting the port area, increasing the speed of gate passing, reducing the congestion phenomenon of gathering and dispersing port operations, reflecting the concepts and development trends of intelligent management, logistics visualization, and information transparency.

Although the Internet of Things is still in its infancy, it can be seen that the Internet of Things based on EPC/RFID technology has been deeply integrated into all aspects of supply chain management. With the application of the Internet of Things in container transportation, it will inevitably lead to the intelligentization of containers. The changes brought about by container intelligence can be reflected in all nodes of the shipping supply chain, creating more value for all supply chain participants. For cargo owners, shippers and carriers in the supply chain, they don’t have to pay any cost. Through various terminals that can access the Internet, they can learn about the status of the goods anytime and anywhere, and enjoy the security and timeliness brought by the intelligent container system. For the ports and freight stations in the supply chain, the use of smart container systems can reduce the labor costs caused by labor employment, and at the same time save a lot of port and freight station monitoring costs. As the government attaches great importance to the Internet of Things, the continuous maturity of RFID and other technologies and the continuous deepening of theoretical research, the Internet of Things will definitely play a positive role in the future development of the supply chain, and its application fields in supply chain management will also increase. The more expansive.

[ad_2]