“Double 11” shopping festival is approaching, RFID helps warehouse logistics + supply chain improve management efficiency

[ad_1]

The “Double 11” shopping festival is coming soon. While consumers’ shopping enthusiasm is being ignited, the express delivery industry, which is inextricably linked to it, has also entered the “war preparation” stage ahead of schedule. This year’s “Double 11” shopping carnival is longer than in previous years. Since October, major e-commerce platforms have “snatched up”. The pre-heating and pre-sales tide has hit, attracting customers to place orders frequently. The result is a substantial increase in the volume of express delivery services.

Since the epidemic, China’s domestic demand market has become a new hope for global business. In order to seize the strongest business growth opportunity during the year, millions of merchants are stocking their products into “Double 11” warehouses.

In warehouses, RFID technology is the most widely used to store and retrieve goods and inventory inventory, and to automate operations such as inventory and pickup. Receiving, picking up, and shipping plans formulated by combining RFID technology with the supply chain planning system not only enhances the accuracy and speed of operations, but also improves service quality, reduces costs, saves labor and inventory space, and saves labor and inventory space. It reduces the loss caused by misplacement, wrong delivery, theft, damage, inventory, and shipping errors in the entire logistics process. Improve the transparency of logistics management and inventory turnover, and improve the efficiency of logistics within the enterprise.

Application of RFID in logistics management

01

Warehousing and distribution management

1) Install rfid readers at the entrance and exit of the warehouse. After the forklift and goods with rfid tags enter the reading area, they are automatically identified and recorded; when leaving the distribution center, the rfid reader at the entrance of the channel reads the tag information and sends it to the system to automatically generate a delivery note; the truck arrives at the destination After the warehouse, the rfid at the receiving port will automatically scan the goods on the vehicle to quickly complete the acceptance.

2) After the forklift and pallet are affixed with rfid tags, the system can track the position of the forklift and pallet at any time. This can greatly improve the efficiency of pallet cargo management and ensure timely and reliable cargo transportation information.

3) When the rfid reader is installed on the conveyor belt of the production line, when rfid label goods pass through the conveyor belt, the goods information can be automatically and quickly obtained and recorded in the system; compared with the traditional manual and file sorting method, it has Features of automatic, efficient and labor-saving. Workers can realize automated operations such as goods entering and leaving the warehouse with simple operations, fast and error-free.

4) Warehouse personnel can collect and query information in the warehouse through the handheld reader, which is convenient, fast, efficient and accurate. After the goods arrive at the destination, warehouse personnel can quickly check the goods through the handheld terminal and automatically record the warehousing situation.

5) When the warehouse staff wear the tag and pass the rfid reader, the system will automatically identify, track and monitor it.

6) Before the truck leaves the warehouse, it is automatically identified by the rfid reader and transferred to the background for data comparison. If the transportation is wrong or lost, the system will automatically alarm to ensure the accuracy of cargo transportation.

02

Real-time tracking management of cargo trucks

1) Put labels on the windshield, cargo and packaging of trucks. When the truck passes through various warehouses along the way, the reader/writer installed at the entrance of the warehouse can automatically identify the truck, record the arrival time and cargo information, and upload it to the system backend for comparison and verification to achieve real-time tracking.

2) When trucks and goods leave the warehouse, they are identified by the reader at the warehouse exit, and the departure time and information are recorded; when the goods exit the line, they are identified by the export reader and record the passing time; when the goods arrive at the destination warehouse , They are identified by the entry reader and writer and recorded the arrival time, and then sent to the back-end server. In this way, the entire transportation process of vehicles and goods is automatically monitored in real time, and the location can be checked at any time through the system.

03

Vehicle access management

Since the vehicle is affixed with an RFID tag, information such as the vehicle and the driver are recorded in the tag. When importing and exporting through the warehouse, it is automatically identified by the rfid reader, which reduces the tedious manual processing, verification and recording, and greatly improves the management efficiency of the freight yard. The system can conveniently query relevant information in real time.

04

Express parcel tracking

RFID channel type counting machine is used in express parcel delivery. When each item is affixed with a passive tag, when the item passes by air and arrives at the airport postal area, the conveyor belt is equipped with an RFID channel antenna. When the package passes through the channel antenna, its position and information will be automatically read and transmitted to The back-end host system checks and compares, and if it finds that the purpose of the itinerary is wrong, it will light up and give an alarm. In this way, RFID ensures 100% mailing accuracy of express parcels.

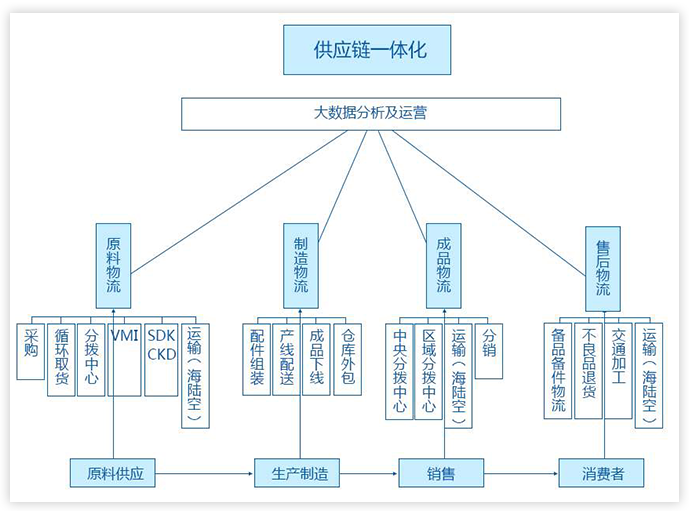

Application of RFID in supply chain management

With the deepening of the globalization of labor division, the supply chain of modern enterprises continues to extend, and features such as fragmentation, complexity, and geographical dispersion have brought great challenges to supply chain management. The finished products are largely controlled by outsourced suppliers. Manufacturing, and the number of suppliers is huge, distributed in various places. This status quo has led to the opacity of the supply chain, and information asymmetry has led to high friction costs. With its fast, real-time, and accurate characteristics, RFID can improve the core enterprise’s control over the supply chain, thereby making it possible to efficiently and accurately trace the source of products. Reality.

Internet of Things technologies such as RFID can build an alliance chain including manufacturers, suppliers, distributors, retailers, logistics companies, end users, etc. around core enterprises, and record the flow of capital, information, and goods on the chain Can not be tampered with, greatly simplifying collaborative work. Real-time recording and sharing of the latest developments in each link of the supply chain allows core enterprises to achieve a penetrating grasp of the supply chain, timely understand the production, quality, and transportation of orders, and make the supply chain transparent and visual.

The transparent construction of the supply chain will realize the information management of goods, improve the management level of manufacturing enterprises, reduce management costs, enhance core competitiveness, increase production efficiency, and shorten capital turnover time.

01

Conducive to the reduction of corporate inventory costs

Reduce the time of commodity inventory, reduce the degree of product backlog, and then achieve “zero inventory”, which greatly saves the company’s raw material supply, warehousing and management expenses, and saves a lot of investment in space costs.

02

Conducive to the reduction of labor costs for enterprises

Make the supply chain reach a high level of automation, effectively save the traditional logistics center resource occupation, labor costs, and save order compound labor and transportation process confirmation costs.

03

Conducive to the reduction of business transaction costs

Inventory can be quickly counted to reduce out-of-stock and out-of-stock products, enabling companies to replenish goods in time to meet market needs.

04

Conducive to the enhancement of corporate brand and competitiveness

Enterprises can eliminate the negative impact caused by shortages and enhance their market competitiveness. At the same time, the quality of customer service can be better improved through visual inventory management, thereby further enhancing the corporate brand image.

05

Conducive to improving the traceability of the supply chain

The modern supply chain encompasses all links in the production and distribution of commodities. From raw materials to finished products delivered to consumers, the supply chain covers a wide range of areas and lacks supervision. Buyers lack a reliable way to verify the authenticity of commodities. The transparent construction of the supply chain can fully improve the traceability of the supply chain and protect the brand reputation.

Summarize

In the field of supply chain and logistics, companies must accurately grasp the flow and changes of logistics in real time, and RFID can provide data input/output, control and tracking in business operations. It has high application value in various links such as procurement, storage, loading and unloading, transportation, distribution and inventory.

[ad_2]