RFID smart warehouse project of a paper company

[ad_1]

1. Project background

A paper production unit is currently the largest manufacturer of household paper and maternity and child hygiene products in China. It has more than 40 independent legal entities nationwide, with fixed assets of more than 20 billion yuan, production and sales networks throughout the country, and market share for consecutive years Ranked among the best in the country.

At present, the company’s original paper warehouse has a total area of 39,000 square meters, with a maximum inventory of 65,000 pieces and an average daily shipment of 2,000 pieces. With the continuous development of enterprises, how to accurately grasp inventory information in real time and how to improve inventory management levels is particularly important. This is an urgent need to build a set of efficient intelligent warehouse management systems to make materials in and out of the warehouse convenient, fast, and accurate.

2. Construction goals

AiTemu intelligent warehouse management system aims at many problems faced in traditional warehouse management, adoptingRFIDRadio frequency identification technology realizes a series of automatic operations such as automatic identification of warehouse materials, accurate inventory positioning, warehouse materials allocation management, automatic/semi-automatic inventory, and real-time report output:

Non-contact automatic identification of the attributes of storage materials

Manage the accurate attributes and quantity of warehoused materials

Realize all-round real-time management of warehousing materials in the allocation process

Use automated/semi-automatic identification methods to improve the accuracy and operational efficiency of inventory

Realize the network real-time sharing and management of warehousing material data, and complete report output according to needs

Accurately locate the storage situation of warehousing materials

Establish a unified asset database to provide a reliable basis for the entire supervision of materials

3. System description

The RFID warehouse management system platform mainly combines the characteristics of RFID technology with the process of warehouse management, and realizes more scientific and visual management on the software. It mainly contains the following modules:

Enterprise client: Solve traditional logistics services, such as inbound entrustment, outbound entrustment, inventory adjustment, report query, etc.

Car-holding terminal: Cooperating with RFID-holding, completing the business processing functions of carrying a car in warehouse management, such as moving the warehouse, which need to be submitted in real time, are the characteristic business processing functions of the RFID smart warehouse.

Mobile work platform end: complete the comprehensive business processing such as receiving and dispatching goods, inventory, picking, sorting, and shifting in the warehouse. The difference from the enterprise client is that it is positioned in the warehouse management business, which is a characteristic business of RFID smart warehouse Processing function.

Handheld terminal: used to complete the binding of location label and pallet label or cargo query.

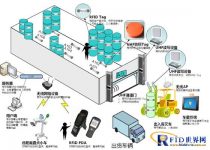

4. System Architecture

This system is a distributed system, and its network deployment structure is as follows:

5. System process

The main process of the system is:

Before the goods are put into storage, the goods information needs to be imported from the NC system to the intelligent warehouse system database. Warehouse management personnel use PDA to perform inspection and submit the inspection information to the system. The system allocates warehouse storage space at the same time. After receiving the warehousing instruction information, the truck will pick up the goods to be put in the warehouse. At this time, the RFID reader of the truck will check the item information Perform verification to ensure that the electronic label information is accurate and start transportation. After the truck is carried to the cargo warehouse door, the RFID reader installed in the cargo warehouse door channel reads the RFID tags and the truck tags of the cargo on the truck and communicates with the storage instruction information Make a comparison to ensure that the electronic tag information is accurate and prompt to release, and the truck will continue to move to the target location. At this time, the truck reader will start to read the RFID tag information of the location and compare it with the warehousing information. After confirming that it is correct, it will prompt the driver of the truck. Put down the goods, and the truck driver clicks submit at this time, and the system updates the inventory table. When necessary, carry out warehouse inventory inventory, just use RFIDPDA or inventory trolley to read RFID tags. When the goods need to be shipped out or moved, the forklift will confirm the location and the RFID tag information of the goods before picking it up, and the RFID device will read the electronic tags again at the doorway of the warehouse to compare the information with the goods out or moved. , In order to ensure the accuracy of the goods out of the warehouse.

[ad_2]