Shenyang Lear Automotive Systems Co., Ltd. applies RFID technology to parts logistics

[ad_1]

With the development of the automobile industry, how the logistics system of auto parts companies responds to the increasing production capacity of OEMs and the complex and diverse product requirements are serious issues facing parts manufacturers. At the same time, with the rapid development of the Internet of Things, the maturity of RFID technology provides new solutions for supply chain data collection, and more and more auto parts companies apply RFID technology to the fields of automotive logistics and supply chain.

Shenyang Lear Automotive Systems Co., Ltd. (hereinafter referred to as Shenyang Lear) is a branch plant established in Shenyang by Lear Corporation, one of the largest auto parts suppliers among the global Fortune 500 companies, mainly providing car seats for BMW Supporting services. Shenyang Lear plans to achieve 675 units/day in 2014, with an annual output of 200,000 sets, which is nearly double the output two years ago. At the same time, the customer requires that all imported raw materials that have a 14-day safety inventory must be stored in the existing warehouse in the factory. Due to the limited space in the factory, the inventory space of domestic parts can only be reduced by increasing the frequency of domestic parts arrival. This requires Shenyang Lear’s logistics efficiency to be greatly improved.

Traditional logistics mode restricts development

Shenyang Lear has an existing assembly line. In the current logistics system based on barcode-led technology, all parts identification methods are paper barcode scanning. Inbound logistics, production logistics and ex-factory logistics are closely related.

In the inbound logistics, the consignee will check the receipt with the actual product. If it is confirmed that it is correct, print the Shenyang Lear internal bar code list according to the ASN (an encoding format) data and paste it on the surface of the goods. The logistics staff The goods are sent to the agreed storage location based on experience, and the storage location information is input into the portable scanner. During production, the batching personnel carry out the batching according to the safety stock requirements of the materials beside the line. For JIT (just in time) parts, find the warehouse location according to experience and deliver them to the side of the line. For the JIS (Sequenced Production) parts that need to be sorted, the batcher uses the ERP (Enterprise Resource Planning) system to print the batching list according to the planned production sequence, and prepare the batching according to the established order on the batching list. Quickly and accurately find the finished products required by the order before leaving the factory. After the delivery is completed, a library record must be made in the system to avoid an inflated inventory of the system.

Although the logistics system of Shenyang Lear has been greatly improved compared with the earlier extensive logistics, and takes the initiative in modern logistics, its drawbacks are obvious. In the years of operation, Shenyang Lear has found that the following problems often occur :

a. The inventory of the parts system does not match the physical object: it often happens that there is inventory in the computer system, but the physical object cannot be found in the warehouse;

b. The batching speed is slow: due to the three shifts of the warehouse staff, the batching staff cannot find the material in the first time, causing production risks;

c. Slow delivery speed: the receiver needs to check and enter the system according to the paper documents provided by the delivery person, which is labor-intensive and prone to human negligence;

d. Materials cannot be first-in-first-out: Because the bar code does not provide the production date of the material, the batcher often picks up the material nearby, which easily causes the material to fail to meet the quality standard after a long delay, and it is also impossible to trace the incoming information;

e. Information flow lags behind logistics: planners cannot track the status of materials in real time, resulting in delayed decision-making.

Introduce RFID technology to revolutionize logistics

In response to the various problems that appeared, Shenyang Lear decided to introduce in the supply chainRFIDTechnology: liaise with suppliers to establish RFID technical standards, so that incoming materials can carry unified standard electronic tags; add RFID equipment inside the company, plan RFID network construction and related hardware as a whole; in the company’s unified QAD system (an ERP system) Add the corresponding RFID software module to integrate it with the production information flow; at the same time, train the company’s employees.

After the introduction of RFID, Shenyang Lear reconstructed the logistics business process according to the logistics model in the factory as follows:

Inbound logistics

The new logistics management system requires all suppliers to carry uniform RFID tags in standard packages, and the IT department will uniformly assign unique identification codes and coding methods for suppliers, parts, and delivery batches. Shenyang Lear sets up an RFID reader at the receiving port. When the goods enter the gate of the factory, it will automatically read the RFID tag information. First, compare it with the ASN information set in the system by the material planner. If there is a difference, contact the planner immediately. Verify the reasons for the differences in parts; no differences are directly received into the system. Since a certain number of readers have been arranged in the warehouse, which can be seamlessly identified, the goods do not need to be stored in designated locations. Forklifts can store goods on three-dimensional shelves according to the principle of being nearby and expeditiously. This setting saves the traditional receivers from ordering and inspecting the goods, greatly saving the time of receiving the goods, reducing the waiting time of the supplier’s delivery truck, and improving the turnover rate of the receiving port.

Production logistics

According to Shenyang Lear’s self-developed JIS system, the batcher introduces the customer’s needs into the system in advance, and batches in advance according to the production rhythm of the production line. Among them, the raw materials are divided into JIT parts such as seat belts, airbags, and headrests, as well as sorted parts such as skins, foams, and mechanism skeletons. For non-sequencing parts, the batcher determines whether to replenish materials according to the Kanban next to the production line and the maximum and minimum inventory next to the production line. When determining the ingredients, large parts such as institutions and skeletons will be directly placed in the designated position according to the shift, and the ingredients can be selected. For non-sorted ingredients, the ingredients staff will first go to the small supermarket to select them. It should be noted that the factory does not open the label package before placing it on the high-level shelf. When the small-item supermarket inventory is less than the minimum safety stock, the batcher can use the portable reader to enter the part number, and then connect to the terminal to read and write according to RFID. Information, find the position of the required parts packaged on the high-level shelf. RFID is used as the unique identification information before the parts arrive in the small-item supermarket. Once the parts are unpacked, they are identified according to the built-in barcode, including subsequent production line scans and online. So unpacking is the point of distinction between RFID and barcode. Since you can see information such as the time of entry into the factory when you select the whole package of parts at the terminal, it also solves the FIFO (First in first out) problem that has plagued Shenyang Lear for many years.

Factory logistics

When shipping, the shipper needs to scan the barcode on the packing list for packing verification (ensure that the seats are installed on the correct turnover cart) and loading verification (ensure that the seats are installed in the customer’s needs and order to be loaded into the shipping vehicle ). Through the application of RFID information technology, a portable RFID tag will be attached to the finished seat when it is off the assembly line. In this way, the information and location of the finished seat can be accurately identified through the readers all over the factory. When loading is required, the shipper can Find the position of the seat directly according to the portable reader. The reader placed at the door of the shipment can accurately read each seat that has been moved out of the factory to enter the delivery vehicle, thereby automatically completing the packing check and the loading check, which greatly saves the shipping time.

Solve problems and achieve efficient logistics

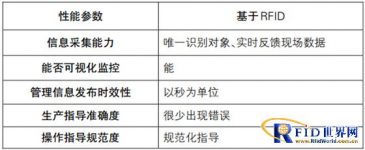

It can be seen from Table 1 (see the next page) that the RFID-based logistics system can identify and track each target, and can collect and track the material flow in real time and accurately; at the same time, the data can be analyzed and sorted and fed back to Managers monitor the production status and logistics flow to achieve visual monitoring and management of the entire production process.

Shenyang Lear reorganized the in-plant logistics information system through the analysis of the current logistics system and business process. At present, most of the problems encountered in actual production have been resolved (see Table 2).

The problems that have plagued the company in many years of practical operation have also been solved in the application of RFID (see Table 3).

The application of RFID has also greatly improved Shenyang Lear’s operating efficiency and customer satisfaction rate (see Table 4).

Through the above analysis, we can see that the introduction of RFID technology into the logistics management system can solve various problems in the traditional mode, better optimize the logistics workflow, and improve work efficiency. In the era of automated logistics, RFID technology will further occupy the high ground of modern and efficient information management for enterprises and play an important role in expanding profitability.

Table 1 Performance analysis of logistics system based on RFID

Table 2 Important changes before and after the introduction of RFID technology

Table 3 Solutions to various problems after RFID is introduced into the system

Table 4 Comparison of efficiency indicators before and after the introduction of RFID

[ad_2]