German women’s clothing manufacturer Gerry Weber will implement labeling of all clothing items in 2010

[ad_1]

Gerry Weber International, a well-known German women’s clothing manufacturer, has decided to use EPC Gen 2 RFID tags on 25 million garments produced annually starting next year. The company is also planning to enable RFID technology in 150 retail stores at home and abroad. The purpose of this application is to improve the efficiency of goods receiving and inventory counting, and to realize the EAS anti-theft function.

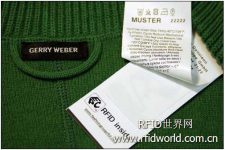

The RFID tag will be embedded in the instruction label sewn into the garment. According to the company, this is the first time that RFID instruction tags have been sewn into clothing in Germany, and it is also the first project that only uses RFID technology for EAS purposes.

The RFID tag will be embedded in the instruction label sewn into the Gerry Weber garment

The company and global label company Avery Dennison jointly developed clothing description labels. Explain that the label contains Avery Dennison’s AD-827 RFID inlay, which is applied to clothing during the production stage. The label can be washed in warm water up to 60 degrees Celsius, and the spin-drying process will not damage the label (this is important because the garment may need to be washed before being sold). When the clothing is checked out at the checkout counter, Gerry Weber employees will remove the label according to the customer’s request, otherwise it will work normally until the number of washings reaches 3 times.

Gerry Weber first participated in a test conducted by Galeria Kaufhof (a department store chain operated by Metro in Germany) and gained experience in RFID applications. Later, in 2008 and 2009, the company participated in the Ko-RFID project-a federally sponsored RFID comprehensive application research.

Gerry Weber itself also carries out extensive and corresponding RFID testing, testing reusable RFID tags in its supply chain to monitor domestic goods, sorting and foreign goods. The tests were carried out in 6 warehouses and two German retail stores. Test partners for RFID logistics processes include system integrator IBM, Checkpoint Systems provides reusable labels and RFID packaging tables, OATSystem supplies middleware, and Intermec supplies RFID handheld devices.

According to Ralph Troger, IT project manager at Gerry Weber, the company realized that RFID applications can obtain “real value” in logistics testing, especially for sorting and outbound goods using the technology. However, he said that for the retail distribution center environment, RFID hardware is too large, and handheld devices also need to improve battery life and reduce weight.

The second test of Gerry Weber was carried out in early 2009. The company tested the application of RFID in the retail sector. Partners included SALT Solution-responsible for the design and testing, Intermec provided handhelds, and Checkpoint Systems provided reusable tags. About two and a half years ago, in Gerry Weber’s first RFID business case calculation, the company was unable to calculate the return on investment of disposable tags, which is why the company decided to test reusable tags.

Gerry Weber allows Chinese clothing manufacturers to apply thousands of reusable labels on clothing. However, the company found that reusable RFID tags are not suitable for retail environments because each time the tag is reused, the new product information must correspond to the tag’s unique ID code.

“The purpose of using RFID is to replace and speed up the process,” Troger said. “Ironically, when you use reusable tags, you add a process-to match the product barcode with the RFID tag.”

The third test was carried out in the spring, summer and fall of this year. Gerry Weber tested the EAS use of RFID in two stores. Partners include system integrator Telekom, RAKO Security Label provided textile RFID tags, and Stonegarden Technologies provided cash register RFID readers and Software used to kill tags.

RFID can be at least as effective as traditional EAS in preventing theft, Troger said. However, he said that the psychological deterrent effect of RFID on thieves may be weaker because the tags are less noticeable.

These three tests and the final calculation helped Gerry Weber come to some important conclusions: The company saw that RFID can achieve the most direct commercial advantage in retail stores. Troger explained that it believes that one-time tags should be applied to all products, not Some commodities can bring return on investment.

“Especially in the goods receiving process, we save a lot of time,” Troger said, “because employees no longer need to manually check the goods or scan barcodes.” Clerks only needs to scan the barcode on the freight bill, and then read the RFID tag on the garment to see if the freight bill matches the actual goods received. In addition, since employees no longer need to apply and remove EAS security tags, time is greatly saved.

“More importantly, customers don’t mind that clothes contain RFID tags,” Troger said. Although the company clearly marked the use of RFID information on clothing, no customers asked about RFID tags in the field test.

The Gerry Weber working group studied the test results and analyzed the business case, and finally decided to use RFID labeling on all clothing in 2010. The company also decided to use RFID in selected stores for EAS applications and other retail processes, and also apply this technology in some logistics processes. Gerry Weber outsourced its logistics to two companies.

The EAS system complies with EPCglobal and GS1 standards. When the product is purchased, the system deletes the EPC ID code of the tag from the database, so that the product will not trigger an alarm when it passes through the EAS export.

According to Troger, Gerry Weber chose Avery Dennison because it is a long-term partner of the company and the first company to provide labels that meet the company’s requirements. Deutsche Telekom provides readers and antennas, including RF antennas specially designed for RFID EAS outlets.

When buying a labeled product, the clerk first reads the barcode on the price tag, then the computer system activates the RFID antenna and reader RFID system under the desktop, and then reads the EPC code sewn into the RFID tag of the clothing and removes it from the database Remove it.

Gerry Weber plans to invest US$4.1 million in the next five years. Troger said the company expects to receive returns within two years of the application. The company will significantly reduce the purchase and sale of traditional hard plastic labels. The company’s logistics partners do not need to install EAS tags on clothing at their distribution centers, which saves a lot of time.

Gerry Weber believes that sewing RFID into clothing will bring business opportunities for suppliers and partners. The company encourages all partner companies to make full use of RFID tags to improve their processes and services by integrating RFID reading points into the supply chain or other points.

The company is also willing to help competitors adopt RFID technology, Troger said, “We welcome competitors to apply this system, and hope that they will also use EPCglobal tags, so that we can all benefit from the cost reduction of RFID technology.”

[ad_2]