RFID technology is applied to Mas men’s clothing

[ad_1]

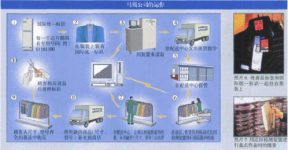

Operation process of men’s clothing

At present, every set of men’s clothing in the store is equipped with a label. This label is installed at the supply yard and used for the management of goods from the distribution center to the store. The company is currently conducting experiments with a distribution center and 6 stores as objects, and the number of products involved is as much as 200,000.

The label application here is different from the food application above, it uses a guided independent printer. Therefore, the label data is a unique number. By comparing it with the database reference data, the inherent information of the object becomes clear.

The process of label management is in the distribution center store and circulation range of the supply yard. The original barcode is used for processing at the POS machine at the checkout counter.

The inventory operation of the store is read by a mobile trolley scanner, and the inventory operation of tags that can read 6000 entries can be completed in 70 minutes. In the past, it took several hours to complete the inventory using barcodes to read, which greatly improved the company’s inventory operations. In addition, since the application of RFID tags is counted after the store is closed every day, the replenishment can be completed before the store opens the next day.

The label cost here is now 35 pence per coin, and the company is considering reducing it to 15 pence. In addition, in order not to infringe on consumer rights, there is no other function that links the information in the label with the sales information. At the same time, the company also told customers about this matter with “this label is only used for inventory management”, and set up eye-catching notices in the store to relieve customers of their doubts about harm to their rights.

[ad_2]