Successful Application Cases of Electronic Supervision of Hazardous Chemicals Gas Cylinders in Shandong Province

[ad_1]

In recent years, the leakage and explosion accidents of hazardous chemical gas cylinders have occurred frequently. In order to reduce the leakage and explosion accidents of gas cylinders containing flammable, explosive, toxic and hazardous chemicals, and to implement a series of decisions of the State Council on strengthening the management of hazardous chemical gas cylinders , The State Administration of Quality Supervision, Inspection and Quarantine, State Administration of Work Safety, and State Environmental Protection Administration jointly launched a special safety inspection and rectification activity for hazardous chemical gas cylinders.

According to the actual situation in our province, Shandong Provincial Bureau of Quality and Technical Supervision, Shandong Provincial Safety Production Supervision Administration, and Shandong Provincial Environmental Protection Bureau jointly issued the “Notice on Implementation of Special Inspection and Rectification Work for Hazardous Chemical Gas Cylinders”, clarifying that It is required to use electronic label technology to supervise hazardous chemical gas cylinders. The Shandong Provincial Bureau of Quality Supervision commissioned the Shandong Provincial Institute of Standardization to develop a set of software and hardware systems for the supervision of hazardous chemical gas cylinders based on electronic label technology. The system has passed the review of relevant experts after trial operation in pilot enterprises. Experts participating in the meeting believed that the system was mature and stable through field inspections and repeated demonstrations:

①Able to reasonably combine electronic label technology with corporate processes and supervisory processes

②Improved the efficiency of pre-charge inspection of filling enterprises, with clear procedures and simple operation, which effectively reduces the probability of accidents

③It is conducive to the work of the inspection station, and the software is easy to use

④Improved supervision, facilitated the work of supervisors, and can cooperate with supervisors’ supervision and management

⑤ Conducive to the conduct of special rectification work

By using the electronic monitoring system for hazardous chemicals and gas cylinders, establish an electronic archive of hazardous chemicals and gas cylinders in the province, and use electronic labeling technology to supervise hazardous chemicals and gas cylinders, and further standardize and strengthen the filling, operation and use of hazardous chemicals and gases The unit’s gas cylinder safety management, and real-time data collection and dynamic tracking in the use registration, filling, and inspection of gas cylinders, so as to achieve dynamic and standardized management of hazardous chemical gas cylinders. Effectively implement the safety responsibilities of all relevant business units, control the hidden dangers of hazardous chemical gas cylinders, improve the emergency rescue of hazardous chemical accidents, and effectively curb the leakage and explosion accidents caused by the filling and improper use of hazardous chemical gas cylinders and waste gas cylinders.

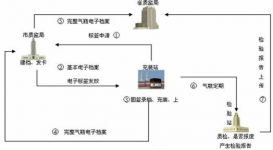

System implementation process:

At present, the system has been implemented in 28 chlor-ammonia filling companies, 23 seamless and acetylene companies, 7 inspection stations, and 17 municipal management departments in Shandong Province. The electronic label mounting rate has reached 80%, and the gas cylinder files have been installed. All are summarized on the provincial supervision information platform, and relevant functional departments only need to apply for query permissions to obtain detailed information about the gas cylinders in use in the province.

Successful users: Dezhou Petrochemical, Hengtong Chemical, Yantai Wanhua, Jining Bank of China, Weifang Yaxing, Shandong Aluminum, Liaocheng Lanwei, Huayang Pesticide

Leaders of the State Administration of China visited the company on site

Shandong Barcode New Technology Development Company is affiliated to Shandong Institute of Standardization, and Shandong Province Gas Cylinder Electronic Supervision System is developed and implemented by our company. In the course of the implementation of dozens of enterprises in the province this year, many valuable experiences have been summed up, especially for the promotion of provinces and cities that are in line with the management status of hazardous chemical gas cylinders in Shandong Province. Relying on its own strength, the company has established a complete sales and service network in major cities to provide users with complete solutions for automatic product identification and high-quality after-sales service. Our services include barcode reading equipment, barcode printing equipment, barcode testing equipment, and barcodes. Sales of label design software; R&D and promotion of radio frequency technology and products; Design and development of automatic identification technology application schemes. The company has a strong technical force, relying on mastering the most advanced automatic identification technology industry trends, leading the market. We always adhere to the tenet of reputation first, customer first, and quality first, and wholeheartedly provide you with a full range of barcode and RFID products and solutions.

Company website: www.autoid.com.cn Contact person: Yang Zhichao 0531-82679345 13685310858

[ad_2]