Application of RFID in food production history

[ad_1]

Taiwan’s agricultural, forestry, fishery, and animal husbandry products have entered an international fierce market, and food safety certification has become an indispensable part. Safety certification is to trace production history to ensure products and increase the added value of the industry.

Understand the food production resume system

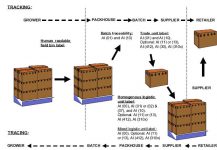

The so-called food production history system refers to the records and keeping records of the source of raw materials or the food manufacturing plant or sales point at the stages of food production, processing, transportation and marketing, so that it can trace the root of the food and its intelligence information. . Tracking in the downstream direction is called tracking (Tracking or Trace forward), and tracking in the upstream direction is called tracing (Tracing or Trace back). The key considerations are:

1. Food and intelligence information should be combined.

2. Records at all stages of the food chain are indispensable.

3. Backtracking in the upstream direction and tracking in the downstream direction must be feasible.

Reference source: GS1 Fresh Produce Taceability

To introduce a food production resume tracking system, the following key elements must be considered:

1. Maintain and keep records of information at all stages

At all stages of food, enterprises should assign identification numbers to identify the food (products and raw materials) and circulate them to their wholesalers and retailers, so that their information is related to each other, and this information should be recorded and kept.

2. Establish a food identification mechanism

The identification and management of food (products and raw materials) is the basis for establishing a production history system. The information of enterprises and their wholesalers and retailers shall be recorded and kept separately. This kind of operation is called food identification management, and it is the basic operation for establishing a production history system. The tasks of identification management are summarized in 5 items:

(1) Decide the unit (identification unit) for tracking products or raw materials, and manage it by assigning ID identification marks.

(2) Manage products and raw materials separately for each identification unit.

(3) Clarify the relationship between product and raw material identification units and their wholesalers and retailers, and record their intelligence information.

(4) Confirm the relationship between the identification unit of raw materials and the identification unit of semi-finished products and finished products, and record their intelligence information.

(5) If raw materials or products are integrated and divided, analyze the interrelationship between the identification units before and after the product integration and division, and record their intelligence information.

3. Choose a common coding system

In the production history system, the use of a common coding system to exchange data is very important from the viewpoint of effective data processing. However, the integration of the coding system used by various enterprises must also be paid attention to. The current international common coding standards include GTIN transaction commodity identification code, SSCC logistics packaging identification code, UCC/EAN-128 attribute information identification code, and GLN business entity identification code.

4. Choose an appropriate method of information transmission

Choose a suitable medium to transfer, store, and verify data methods, including paper documents, barcodes, two-dimensional barcodes, and RFID electronic tags. Each information delivery medium has its own technical limitations and product-related economic costs. Therefore, if you want to introduce a production history system, you must choose a type that suits the information delivery medium when building the system.

Advantages of applying RFID to food history system

1. Prevent forgery of certification marks

The government unit is planning a food history tracking system, hoping that through such a management mechanism, it will meet the quality assurance system and clearly know the origin and batch identification of the food; in terms of safety and health issues, it can also solve the problem of food safety. For defective or contaminated products, perform batch recovery and remediation operations in a precise manner; the combination of RFID and certification marks can prevent forgery, and can respond quickly when problems arise, and clearly define responsibilities to help combat the endless emergence Fraud incident.

2. Product history tracking automation

Regarding the above picture, we know that more information has been requested on the food resume, including food name, food description information, food batch specific information, food traceability and food identification, etc. Food resume tracking must record every item If you scan the ID codes one by one with the barcode, it is time-consuming and laborious, and it is not easy to be uniquely identified.

In addition, the above information needs to be updated and loaded differently when following the food. It is better to exist in the food itself, which can be automatically read by RFID and has the effect of portable identification.

Application environment and recommendations that must be considered

Looking around the current identification system of the domestic food production resume system, whether it is the identification system selected for rice, fishery products or fresh fruits and vegetables, it is now a good time to officially introduce how to make Taiwan’s food production stage leap to the international market, and how to interact with the international market. The problem of market integration is not only the problem of improving the appearance and quality of food, but the relevant safety certification system, the international common number identification and tracking history system are also key factors for success.

[ad_2]