Application case of RFID metering system in a power plant in Baotou

[ad_1]

The importance of measurement management in the production process

The role of measurement in an enterprise: The practice of enterprise development and enterprise technological progress has proved that measurement management is a branch of enterprise management and a science, and measurement management and measurement science and technology are closely related to the same system engineering. Enterprise measurement management requires orderly and autonomous management under the control of the legal system. The establishment of a measurement and testing system provides enterprises with measurement assurance and testing methods to ensure uniform and accurate measurement values, so that the measurement instruments within the enterprise can be effectively managed. For large engineering projects, from plan review, drawing design, production process to parameter (data) measurement, product acceptance and other links, measurement management and technical personnel should participate in providing measurement supervision and assurance for the enterprise from beginning to end.

Metrology is the technical basis for achieving intensive production: the establishment of a scientific and complete metrology and inspection system is a necessary condition for enterprises to strengthen management and effectively organize socialized mass production. In the process of realizing the transformation of economic growth mode, metrology is an important technical foundation.

Measurement is the basic guarantee for realizing economic accounting and reducing costs: enterprise production and operation accounting, energy saving and consumption reduction, cost accounting and other management are the production links of enterprise operation and management. If the measurement is not in place, it will affect the economic benefits and reputation of the enterprise. Therefore, strengthening enterprise measurement is the basic guarantee for economic accounting and cost reduction.

Metrological testing is an important means to improve product quality: without accurate measurement, there will be no reliable data, the process cannot be controlled normally, and it will be impossible to produce high-quality products. The level of metrological testing reflects the level of product quality of an enterprise to a certain extent. Product standards can only be formulated through metrological testing. Whether the product meets the prescribed standards will also depend on metrological testing, identification and inspection. In order to achieve high-quality and high-yield purposes, it is necessary to continuously promote the adoption of new technologies and new processes. Therefore, without advanced and scientific measurement and testing methods, there will be no advanced product quality. The quality management of industrially developed countries uses complete measurement and testing methods as its technical basis to ensure product quality.

Energy metering is the basic condition for scientific energy use: Energy metering is an important technical basis for enterprises to conduct scientific management and save energy. Improving energy metering equipment and strengthening energy metering management are important links and effective measures for energy conservation.

Advantages of RFID metering system

Improved internal transparency: Through the “one card to the end” of the driver, the need to check the manufacturer, coal type, and sampling tank number and other related information is eliminated. In the process, the driver always uses the card as the basis for operation, which realizes the confidentiality of the manufacturer’s data and other information from the internal operators, thereby effectively preventing the possibility of internal personnel accepting commercial bribes. The unmanned process of weighing has effectively controlled the possibility of cheating in the weighing link by the staff of SILB.

Prevent cheating: The infrared and other devices of the unmanned truck scale effectively prevent the car from pressing the edges and not being completely on the scale;

Using the RIFD card as the basis for vehicle identification prevents the occurrence of decking.

Through the analysis and sorting of vehicle historical data, it can effectively prevent the cheating of vehicle tare.

It can be combined with factory-level monitoring or expanded based on the existing system to save the weighing screen of each car, that is, to prevent cheating.

Ease of management: The weighing sequence can be controlled by recording the sampling sequence, thereby realizing automatic queuing of vehicles and facilitating the operation and management of on-site personnel.

The implementation of the system has achieved the effect of one card at the end, saving the generation of many intermediate documents and improving management efficiency.

The unmanned truck scale is equipped with a complete voice prompt system, road pole control, command light system and LED display screen. Through voice and visual prompts and commands to the driver, it reduces the workload of the on-site personnel.

Improve efficiency: The implementation of the RFID metering system can effectively improve the throughput rate of the existing metering system, and at least double the working efficiency of the existing system without building a new electronic scale.

Streamline personnel: The implementation of the unmanned system has effectively improved the work efficiency of on-site personnel.

The implementation of the RFD measurement system removed the manual measurement link and streamlined enterprise personnel.

Application case of RFID metering system in a power plant

Introduction: After comprehensively considering the economic benefits of the enterprise and the implementation cost, a power plant in Baotou City took the lead in the industry to use RIFD technology to manage the metering of coal entering the plant, and upgrade and transform the company’s original process. Achieved the goal of unmanned.

Original process

The factory’s coal loading management before the RFID system upgrade is based on the “coal loading notice”, and the specific process is as follows:

1. Generate a notice. The purchaser generates a “coal delivery notice” in the original information system according to the purchase contract every day. The generated notice contains the date of coal delivery, coal type, manufacturer number (the name of the manufacturer is confidential to other internal links), and the documents Serial number and other information. After the purchaser generates a notice, it is sent to the coal merchant. Coal dealers dispatch vehicles according to the notice, which is usually one vehicle per order, and the receipt is valid on the same day.

2. Sampling coal dealers hand over the car bill to the coal truck and send coal to the factory. The coal must be sampled first. The sampling process is that the driver of the coal truck will inform the sampler of the number of the sent car, and the sampler will use the paper report obtained in advance. Switch the sampling machine to the corresponding sampling tank. Sampling is done afterwards.

3. After over-sampling, the heavy-duty process of the coal car to the weighing room. The specific process is that the driver will show the notice to the weighing staff, who will enter the order number in the existing system, and the vehicle number and model Entering, and then weighing. The weight data is real-time collection of the original system with instruments.

4. Receipt. After weighing the coal truck, go to the coal yard to unload the coal. At the same time, the coal management personnel sign the coal loading notice to prove that the coal truck has entered the yard. If necessary, deduct the weight, that is, write the sensory judgment of the coal quality on the notice, that is, the deducted weight.

5. Tare back/print scale sheet After unloading the coal truck, go to the light scale in the weighing room for backing. Tare is still based on the notice, and the weighing staff will record the tare weight and print out the weighing list.

RFID metering system process

1. Card issuance After the sample purchaser sets the coal type, the manufacturer, and the coal delivery date in the system, the RFID card is issued in batches, that is, the card is initialized. The initialized card is used to replace the original notice and is sent to the coal merchant.

2. After the sampling driver gets the card, he will swipe the card for sampling. During sampling, the sampling personnel will input the vehicle number in cooperation with the monitoring system. During sampling, the system will automatically take the sampling tank number information from the card and send it to the upper computer of the sampling machine. , Realize the automatic can change of the sampling machine.

3. Overweight After sampling, the coal truck is weighed on the RFID unmanned truck scale. In the specific process, after the system senses that a vehicle has entered, it starts the scanning system and scans the card. After scanning the card, it waits for the scale data to stabilize and then writes the weight data.

4. Receipt The RFID system is equipped with RFID handhelds for coal yard personnel. When unloading, the coal yard personnel scan the card to obtain vehicle information, and operate the PDA to input the receipt/deduction information. The data will be written into the database in real time via the wireless LAN in the factory.

5. Leather backing After signing/unloading, the coal truck performs a backing operation on the unmanned truck scale.

6. Receiving card/printing the weighing list. After the tare is returned, the driver inserts the card at the unattended automatic card collection terminal. And the terminal system will automatically play out the pound singles.

Comparison of old and new systems and implementation effects

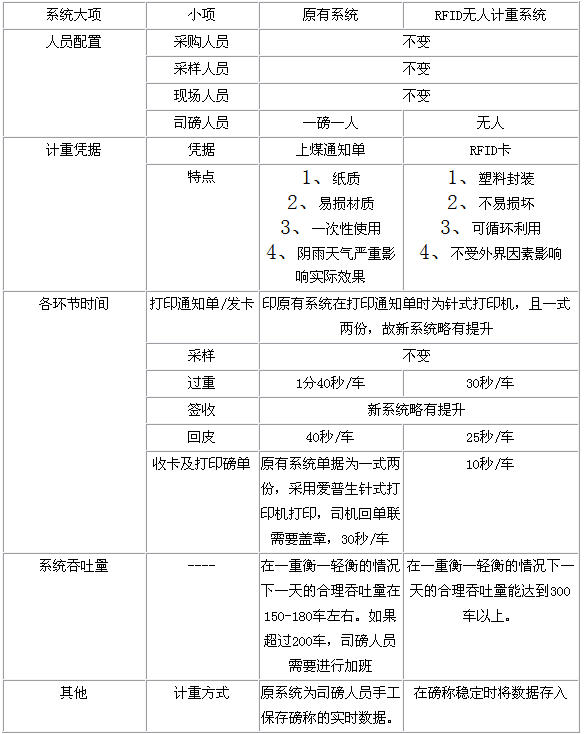

After the implementation of RFID technology, the efficiency of the coal loading process of the plant has been significantly improved. The specific comparison data are as follows:

[ad_2]