Application of 3D Inspection Technology in Printing Quality Inspection

[ad_1]

Principles of Visual Inspection and 3D Defect Inspection

Printing defects can be divided into two-dimensional defects and three-dimensional defects according to their spatial characteristics. Two-dimensional defects are conventional printing defects such as poor overprinting, color cast, missing printing, missing printing, scribbling, missing hot, and hot residuals; three-dimensional Defects are related toLabelThe plane has defects of physical space difference, such as bubbles, scratches, glue overflow, creases, embossing defects. The main purpose of the printing quality inspection system based on vision technology is to ensure that the above two types of defects can be completely detected. The traditional printing quality inspection is mainly done manually, and the main purpose of the quality inspection system based on vision technology is to replace the human eye.

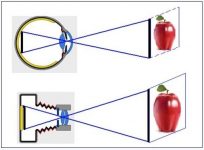

There are two aspects to the human eye’s ability to perceive printing defects, one is the spatial resolution model (that is, the size), and the other is the contrast resolution model (that is, the contrast between the defect and the background). The visual imaging technology realizes the imaging of objects through the simulation of the human eye, and simulates the human brain through software processing. This is the so-called “implantation of the eyes and brain into the machine”. Human eye imaging and visual imaging The comparison is shown in Figure 1.

Comparison of human eye imaging and visual imaging

It can be seen from the figure that the CCD pixels of the camera replace the human retinal cells, the lens replaces the human lens, and the lens aperture replaces the human pupil, thus forming a set of optical system to replace the human eye.

Three-dimensional printing defects, such as bubbles, scratches, glue overflow, creases, embossing, etc., are usually difficult to reliably detect manually. They can only be detected when the direction of the human eye and the defect is at a certain angle under certain optical conditions. When manually detecting such defects, the detected object needs to be rotated at any angle before the human eye can detect it. The angle of visual imaging is fixed. If you want to imitate artificial rotation of the detected object, it will undoubtedly increase the complexity of the entire detection system. For this reason, after studying the optical characteristics of such defects, Beijing Lingyun Company took the lead in the world to develop an optical system specifically for detecting 3D printing defects. The schematic diagram is shown in Figure 2.

Optical system for detecting 3D printing defects

Three-dimensional defect detection effect and performance

After collecting good images of three-dimensional printing defects and combining the image characteristics of such defects, Beijing Lingyun Company has conducted research on related image processing algorithms for such defects, and has developed a special detection software for detecting such defects, and its detection effect As shown below:

Detection software for detecting this type of defect and its detection effect

Detection software for detecting this type of defect and its detection effect

The three-dimensional defect detection developed by Lingyun has four major characteristics:

Super defect detection ability: can detect shallow scratches with a depth of 0.02mm and tiny bubbles of 0.1mm2;

All-direction defect detection: the same detection capability for three-dimensional defects in all directions;

Innovative optical system to achieve full width detection: the maximum detectable width can reach 1000mm;

Dedicated algorithm software: The use of dedicated software can achieve high-precision detection.

Since Lingyun first developed a detection system for 3D printing defects in 2011, it has beenLabelHe tobacco label printing companies have been well applied, and the visual inspection system has truly realized 100% full coverage of printed product defect detection, which provides the best detection method for the majority of printing companies to improve the quality of printing.

[ad_2]