Application of RFID technology in Boshiwa clothing

[ad_1]

client needs

The Boshiwa brand was founded in 1996. The Boshiwa brand contains the concepts of vigor, vitality, wisdom and nobility. Through this brand, the Group provides mid-to-high-end children’s clothing, footwear and accessories to children from newborns to 14 years old. The brand has a variety of styles and is well-loved by consumers. It has been awarded the “Famous Brand Products” and “Shanghai Famous Trademarks” for more than ten years, and was awarded the “Top Ten Children’s Clothing Brands in China” in 2007 and 2010. title.

The current warehousing and inventory checking are carried out by scanning the barcode on the tag. The barcode has the advantages of low cost and simple operation. However, the barcode recognition process also has some inherent disadvantages, such as the poor penetration of the barcode recognition process, which must be extremely small. The barcode recognition process cannot be read in batches, only one barcode can be read at a time; there are many misreading situations in the barcode recognition process, because the barcode is printed on the paper medium and is easily damaged and destroyed. caused. In addition, the information that the barcode itself can represent is too single to describe more characteristics of a certain piece of clothing.

Boshiwa has a diversified sales channel, in addition to department store brand counters, street shops, Boshiwa 365 living hall, and main stores, there are also emerging wholesale and online store sales channels. Apparel products are a kind of fashion products. Many factors such as the season of sale, the location of the sale, the taste of consumers, the fashion trend, the price of the product, and many other factors will affect the sales of the product. Therefore, real-time tracking of clothing products from production, logistics, sales to returns and exchanges is a very important management content for clothing industry enterprises.

The company hopes to informatize all aspects of clothing production, product processing, quality inspection, warehousing, logistics and transportation, distribution, and product sales, to provide users with real-time dynamic tracking and query throughout the process; to achieve monitoring of processing information, system operation status, and business operation quality At the same time, it provides real, effective and timely management and decision support information for managers at all levels to provide support for the rapid development of the business, thereby comprehensively reducing costs and improving corporate profits and competitiveness.

Scheme realization

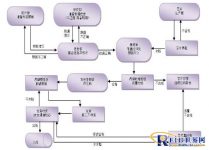

Solution process

Finished product management-production management

• After receiving the order, prepare the production plan. Associated with ERP system data.

•According to the system instructions, the information is fed back to the label production center, and RFID labels or listing work orders are printed.

Finished product management-tag management

Traditional product history recording operations are usually time-consuming and cumbersome, resulting in poor performance by field operators.

andRFIDWith the feature of non-contact sensing and reading of label data, the difficulty of importing and executing on-site personnel will be greatly reduced, making the product production history database more complete, and management analysts can propose effective production management improvements accordingly plan.

Warehouse management-inventory/picking management

With the characteristics of RFID wireless sensing, the inventory and tally of the goods in the warehouse can also be carried out at any time, thereby shortening the time required for the annual inventory operation, or even without the need for a special closure action, to perform the inventory inventory operation.

Solution-Logistics Management

System benefit analysis

Compared with the traditional operation mode, it can greatly improve the efficiency of the warehousing point collection, and add the warehousing inspection work that was not done before to the warehousing point collection link, and reject the problematic products from the warehouse from the source of the warehousing. Outside the door, the 100% accuracy rate of the goods in the warehouse is ensured, which provides a strong guarantee for the accuracy of the inventory data. It also reduces or avoids a lot of manpower and material costs for later management.

System Features

The system can be informatized from clothing production, product processing, quality inspection, warehousing, logistics and transportation, distribution, and product sales, providing users with real-time dynamic tracking and query throughout the entire process; achieving information processing, system operation status, and business operation quality Monitoring and management, while providing real, effective and timely management and decision-making support information for managers at all levels to provide support for the rapid development of the business, thereby reducing costs in an all-round way and improving corporate profits and competitiveness.

> Finished product management, this stage of operation is an extremely important position for the RFID system. In this work phase, the product will be completed. The RFID tag is usually attached to the product from this, so that the RFID control cycle officially begins.

•Automatically record the parameters required for production management

•Real-time recording of product packing records

•Improve the accuracy of packing and ordering content

• Storage location records of unpacked finished products in the temporary storage area

> Warehouse management, in most companies, is an urgent goal for improvement. The space of the warehouse is limited. How to properly plan and implement the “first in first out” principle in the limited storage space, and speed up the in/out of various raw materials, finished products, and semi-finished products is this stage The main goal to be achieved.

•Accelerate the time of cargo warehousing and counting

• Shorten the time schedule of inventory counting operations in warehouses

• Achieve real-time inventory goods inventory function

•Quickly find the location of physical goods

•Saving time for comparison of shipping lists

> Sales & service, the application of RFID technology in the sales link, the presentation of its benefits mainly focuses on the aspects of warehousing inventory, store inventory, tally, anti-theft, anti-counterfeiting, member collection service, and consumer behavior analysis;

•Points exchange/market analysis:

•Maintenance Warranty/Customer Service:

•Cross-stock prevention/brand protection

• Commodity anti-counterfeiting

• Anti-theft security

•Consumer behavior analysis

[ad_2]