Application of Station Management System of Shanghai Ren Microelectronics Production Line

[ad_1]

1. System significance

1) It has realized the intelligent statistics of the production line flow operation, the monitoring of the production process from time to time, and the time-consuming automatic statistics of each station, etc., replacing the traditional manual statistics method, and achieving the maximum intelligence of the information words of the production enterprise.

2) Improve the utilization rate of working hours and production efficiency on the production line, and make up for the phenomenon of empty time and empty lines caused by missing parts and lines in the production of a single product.

3) Real-time attendance of station staff, monitoring the working status of on-duty staff.

4) Real-time status tracking of the whole process. Accurately understand the position and status information of the work-in-process, and provide an accurate basis for product problem tracking and quality tracing.

5) Through real-time monitoring of workstations, understand the processing and assembly process of products in progress, reduce abnormal handling time, and improve on-time completion rate and delivery rate.

2. System architecture and program description

In order to improve the transparency of the production process and the comprehensive information construction of the enterprise, to achieve the purpose of improving efficiency and reducing costs, production enterprises urgently need a set of control management systems that meet the management of the production line to solve the insufficient ability to monitor the status of the production site and the ability to coordinate between stations Poor, lack of effective guidance on site operations and ingredients, and delayed quality data entry. Shanghai Renwei Electronic Technology Co., Ltd.’s production line station management system based on RFID technology has become one of the effective solutions to the above problems. By adopting RFID technology, the system can automatically collect production data and equipment status data to provide production managers with enterprise business processes The real-time data of all links can allow the online monitoring and analysis of production information such as process parameters and equipment operating parameters of each important link in combination with the process characteristics of each process equipment and related process and quality index parameters to help enterprises realize the production process The measurement of semi-finished and finished processes, the automation and information integration of warehouse warehousing management, automatic real-time tracking of the supply chain, sales and after-sales service feedback, so that business leaders can grasp process information in real time and supervise and manage business operations Supervise. At the same time, through the combination with various management systems of the company, the production status of each order can be inquired in time, so that the company’s managers, procurement, logistics and other departments can monitor the production status of any order in real time, and schedule production, material procurement, and customs. Provide dispatch basis for customs declaration and logistics transportation.

2.1 System architecture

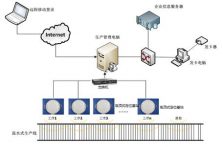

System network architecture

2.2 Program description

As shown in the figure above, we useRFIDSemi-active technology is used for production line station management. In each monitored station, a semi-active positioning base station is installed, which is our company’s ceiling-mounted positioning base station. In our workstation management system, the positioning base station is the smallest base point. As the most basic base point of the positioning point, the distance between the activation tags is 3-5 meters, that is, each tag is located 3-5 meters away from the base station. When the range is activated, its positioning accuracy can be described as 3-5 meters. The positioning base stations of different stations have their own unique address codes. When personnel or work-in-progress enter the positioning base station with a semi-active low-frequency activation tag and are activated, the tags work normally, and the ID number of the tag is sent to the outside world, and at the same time. The address code of the activating antenna of the positioning base station that activates the tag is output, so that by activating the address code of the antenna, we can locate the station where the tag is located. When the tag is taken from one station to another, the uploaded activation antenna address code will also change accordingly. In this way, a complete positioning system is formed. The data uploaded by the label is received by the positioning base station gateway on the workstation, and the information is uploaded to the information monitoring center for processing. The information monitoring center always displays which process it is in, how many processes can be completed, and how long each process takes , How long does each station take? This system records the on-the-job status, production status, and output of each production line in real time. The management personnel can easily optimize production efficiency and improve production quality according to the number of products to be produced and the flow progress. With the help of advanced technology, the realization of intelligent, automated, and informatized production has enabled a qualitative leap in the overall production and management level.

Three, typical cases

Sany Heavy Industry

[ad_2]