Avery Dennison helps Levi’s 3,000 stores worldwide popularize RFID applications

[ad_1]

In the late 19th century, Levi Strauss invented the first batch of jeans as their overalls for cowboys, prospectors and farmers in San Francisco. Since then, solid and durable overalls made of denim have become popular all over the world. Today, Levi’s has once again led the way in the application of RFID technology. With the joint efforts of Avery Dennison and its partners, Levi’s plans to have UHF RFID tags in its 3000 stores around the world by 2021. Store inventory management.

Customer pain points

Store inventory is difficult to match customer needs

Take Levi’s jeans products as an example. Different cuts, colors, washes, lengths and sizes are arranged and combined to form a large number of single product models. Usually, there are about 120 kinds of women’s jeans, and there are more than 80 kinds of men’s jeans. In the traditional way, the efficiency and accuracy of inventory counting have reached a bottleneck. This leads to some common problems on the store side: customers often cannot find the ideal style in the current store, or the store’s replenishment mechanism is not triggered in time after the product is out of stock.

RFID decoding bottleneck in retail industry

Achieve more than 98% inventory accuracy rate in 20 minutes

Levi’s has been exploring the use of RFID technology to meet a series of challenges faced by stores since 2016. After sufficient testing and evaluation, Levi’s began its plan to promote the use of RFID in its global stores in 2018.

At present, all Levi’s US stores have applied RFID, with a total of 50 million single products. The promotion and popularization of European stores is also underway at full speed, and then, the implementation project of Asian stores will also be launched. Levi’s plans to extend RFID technology to more than 3,000 stores in its three largest markets in the world-North America, Europe and Asia by the end of 2021.

More than 50 million Levi’s items have been affixed with RFID tags

Avery Dennison provided all pre-encoded labels for Levi’s RFID project, starting from the production side, giving each item a unique digital identity. Through RFID technology, the inventory count time of the entire store is shortened to less than 20 minutes, so that the store can complete a complete inventory count twice a day, and the average inventory accuracy rate exceeds 98%.

RFID tags shorten inventory counting to 20 minutes, which can be completed twice a day

RFID helps achieve sales growth

Through RFID technology, Levi’s can better sell its favorite products to its customers, so as to achieve sales. Mr. Stefan Otte, vice president of global commercial real estate and partner retail of Levi’s, said in a recent interview: “Nearly 100% inventory accuracy has helped tap new sales potential. For stores that have already applied RFID, their average performance growth has reached 5%. More importantly, the implementation of RFID can integrate more functions such as omni-channel shopping and self-service terminals.”

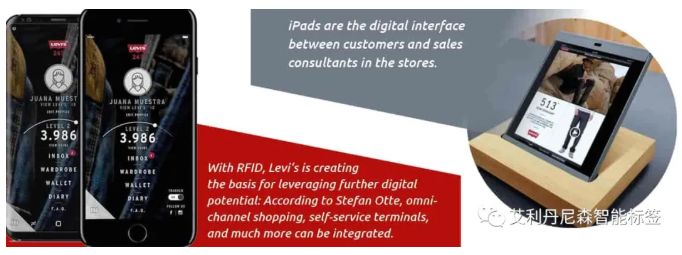

If a product is indeed not sold in the store or is out of stock, the clerk can recommend similar styles to customers through the tablet, or transfer the goods to other stores, and deliver them directly to the current store or even the customer’s home.

Interaction with customers can be completed only through the tablet

The retail industry without RFID will have no future

Mr. Otte said: “RFID technology is becoming a standard. In the trade of goods, customers and products should be the focus. The implementation of RFID technology has promoted the realization of this goal. Employees will become digital shopping experts and better recommend them to customers. Products that have not yet had the opportunity to personally touch. The retail industry without RFID will have no future.”

[ad_2]