Balluff RFID: “pinion gear” turns a new era of 5G artificial intelligence

[ad_1]

The fifth-generation mobile communication technology, that is, the recently spread word-of-mouth 5G technology, is a new generation of cellular mobile communication technology based on the 4G network.

The high-speed, reliable, low-latency, and hundreds-billion-level connection capabilities of 5G networks have brought new possibilities for the Industrial Internet of Things, and also helped the manufacturing industry to improve quality and increase efficiency.

Not long ago, an innovative smart factory located in Pudong, Shanghai realized the application demonstration and all-round empowerment of artificial intelligence, making human-computer interaction more convenient. The factory connects scattered materials, shelves, equipment, etc. into an overall Internet of Things system, which greatly improves the efficiency of the production line and reduces input costs.

And behind this is also inseparable from the promotion of Balluff RFID “pinion gear”.

Balluff RFID and IO-Link solutions

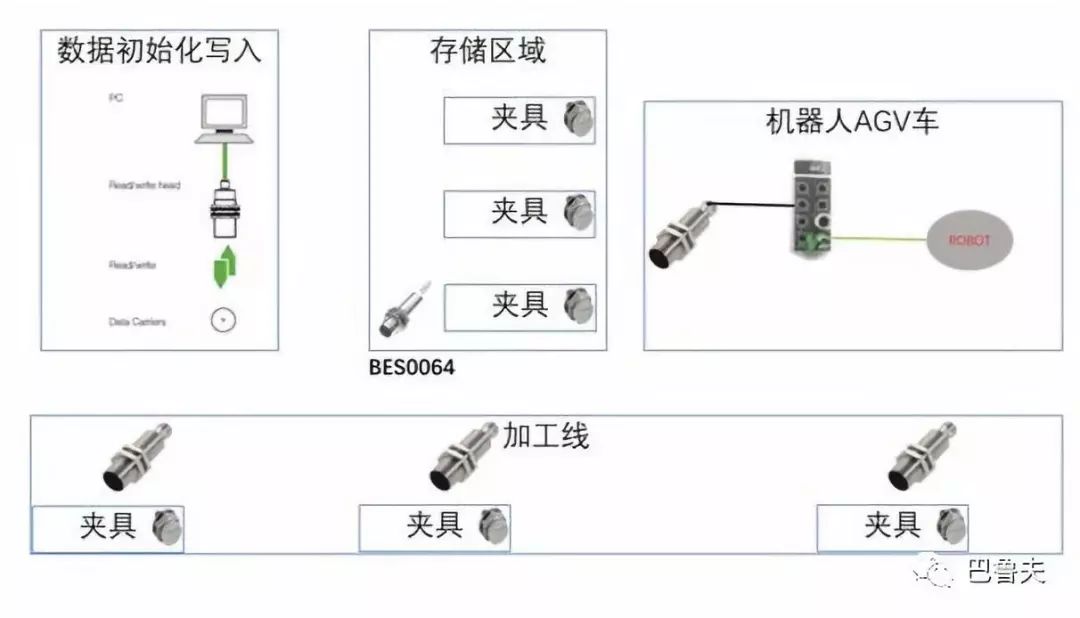

The factory’s machine tool tool automation management system uses Balluff RFID and IO-Link solutions. With the help of the 5G network, the wireless signal of the industrial sensor is transmitted to the host computer more quickly and reliably, and the tool is adjusted by the AGV robot Carry out pick-and-place and path planning, and finally realize unmanned pick-and-place and management of tools required for machine tool processing.

Balluff’s small size RFID chip is directly mounted on the tool

IO-Link solution for machine tool information management

Balluff RFID and sensors realize tool positioning and information storage

Balluff’s small size RFID read-write head is directly installed on the robot gripper

[ad_2]