Detailed explanation of the status quo of the application of RFID technology in clothing production

[ad_1]

my country is the world’s largest garment producer and exporter, and garment enterprises have made outstanding contributions to the rapid growth of GDP. However, most clothing companies still use traditional production management methods, with low degree of informatization, obvious problems and ills, which are mainly reflected in the following aspects: unable to grasp the actual production status and material status, and unable to allocate and adjust tasks and materials in a targeted manner. Effective production time is often less than 60% to 70% of working hours; product quality problems are difficult to accurately trace back to the responsible person, strict quality supervision is not possible, and product quality levels are low; materials flow between various links of production cannot be accurately tracked, and materials are lost and wasted. Frequent, cost artificially increased; unable to control the real-time progress of various production tasks, high risk of overdue orders, and difficulty in scheduling and coordinating multi-task production resources.

These problems have seriously affected the overall benefits of garment manufacturers. Since 2008, with various unfavorable factors such as the appreciation of the renminbi, rising labor costs, and reduced external demand caused by the financial crisis, the apparel industry has faced greater pressure to survive. For garment enterprises to continue to survive and develop, it has become necessary to use information technology to solve problems in production management and improve their core competitiveness.

The problems and solutions of clothing production informatization

Clothing manufacturers generally have the characteristics of multiple product styles, complex processes, large batches and small batches, and high individual requirements for orders, which are reflected in the large amount of information, multiple types, complex associations and processing rules between information in the information model. To realize the information management of production, apparel companies first face a difficult problem: how to collect and provide real-time and accurate information about the underlying status of a large number of materials, semi-finished products, personnel, and equipment in the production process to the management.

Traditional information collection methods cannot solve this problem. For example, manual recording methods cannot guarantee the real-time and accuracy of data; the recognition rate of barcode labels is affected by the dust, fiber pollution and the dynamic characteristics of materials in the clothing workshop, which will reduce the reliability. The lack of effective information collection methods is one of the important reasons why traditional MES and other information systems cannot fully function in the clothing production process.

The characteristics of RFID technology determine that it has the following advantages in the production process information collection:

1. It can realize the seamless integration of production logistics and data information flow without affecting the normal operation of production materials;

2. Using the electromagnetic field coupling method, it can be used normally in the environment where the workshop is full of dust, fiber and other pollution;

3. The label has the function of reading and writing information, which can realize the localized storage and reading of production object information;

4. The label adopts a globally unique identification code and a complete security authentication mechanism, which can prevent label forgery and malicious tampering of data.

The status quo of the application of RFID technology in clothing production

Although RFID technology has obvious advantages in production informatization, the application of RFID in domestic and foreign clothing manufacturers is not yet mature. In a small number of application cases, electronic tags are used to replace paper work orders to store information, and RFID technology is not really used. The advantages. There are several main reasons for this status quo:

1. Domestic clothing companies are mostly in the downstream of the industrial chain, with low profit margins and cost-sensitive, unable to introduce expensive industrial RFID equipment and systems from abroad.

2. The application of RFID technology in the clothing production process is quite technically difficult, and domestic research in this field started relatively late, and more stayed at the system architecture and software level research, and there was a lack of industrial RFID readers, middleware, and real-time information transmission. Research and breakthroughs in the underlying key technologies such as data processing and data processing.

In response to the application requirements of RFID technology in the informatization of clothing production, relying on the national 863 project funding, Beijing Sanbo Zhongzi Technology Co., Ltd. focused on the applicability of RFID in the clothing production process and key applications, and built an RFID-based clothing production informatization Management system to solve the problems existing in the management of traditional clothing production process.

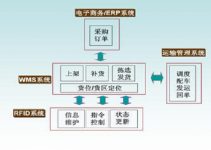

Overall design and application realization of RFID-based clothing production information management system

The relevant links in the production process of a typical garment processing enterprise mainly include: production task formulation and release, raw and auxiliary materials receiving, processing and production, quality inspection, and packing. Targeted application of RFID technology in the production links of typical knitted garment enterprises, collecting on-site information of each link and summarizing it to the enterprise information server, building an RFID-based clothing production information management system, mainly realizing production task schedule control, production material tracking and core production links Real-time monitoring and dispatching and other functions.

Production task schedule control

In order to realize the real-time collection and control of the progress of each production task, an electronic label task card is generated for each production task from the time it is formulated and issued. The task card saves necessary task information and is held by the production manager of the task. Each production process link of raw and auxiliary materials receiving, processing and production, quality inspection and packaging is equipped with RFID reading and writing equipment, which is used to collect or write task progress related information, and upload it to the enterprise information server for real-time viewing and processing by management .

The formulation, release and management of production tasks are completed by the Planning Department. When the planning department issues each task, it writes the task-related content into a 13.56MHz electronic tag (task card) and sends it to the task manager. The data storage of the task card is divided into UID area, basic information area and process information area. The UID area is an independent partition, which stores the globally unique code of the label, which is solidified and cannot be changed when the label leaves the factory. The basic information area stores task information such as task number, quantity, style, delivery date, etc. Only the planning department has the write permission, and other production links have only read permission for this area; the process information area is divided into different sub-areas for different production links. Each link can write or read corresponding information in the corresponding sub-area as needed during the production process.

[ad_2]