RFID clothing station management improves production management efficiency

[ad_1]

In the production process of traditional manufacturing enterprises, the previous production mode is dominated by single-piece production. Once this single-piece production line mode encounters complicated procedures and many production links, various problems are prone to appear. The clothing manufacturing industry is a typical labor-intensive industry, with its unique business processes and cumbersome procedures. Clothing management has been the optimization standard to improve production efficiency and shorten the capital turnover time. RFID technology performs automatic data collection on various process links of the production line, and provides the production platform with data on all process links of the production line. RFID technology automatically collects the process characteristics of each process equipment and related process and quality index parameters, and online monitoring and analysis of production information such as various process parameters and equipment operating parameters.

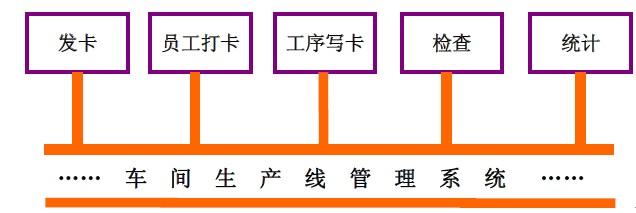

RFID clothing station management uses RFID electronic tags as information carriers for employees and clothing, and uses wireless networks and the Internet as information channels to establish a complete information management system, which can control the entire production line for employee cards, stations, and clothing materials. Cards and other links are recorded throughout the process to realize automatic data collection and real-time tracking management of products in production, so as to realize real-time tracking of logistics and information flow on the production line of the enterprise, and improve the work efficiency and service level of enterprise production management. RFID realizes the automation and information integration of semi-finished and finished processes in the production process, as well as the warehousing and inbound and outbound management of the production process, so as to achieve automatic and real-time tracking of production operations, which can effectively supervise each production post and monitor product quality. Stability and implementation rate of process parameters are monitored.

The RFID production line management system uses electronic work tickets instead of traditional paper work tickets, uses an RFID electronic tag for each single product on the production line, and installs a Shanghai Yingxin Information RFID data collection at each station Electronic tag reader. When a worker completes a job, the system automatically sends the information of the workpiece directly to the computer system through the RFID electronic tag reader. The system automatically completes piece rate calculations and various production statistics, providing a complete set of workstation management for the enterprise And production schedule solutions.

The RFID production line management system efficiently and accurately solves the problems of wage calculation and work-in-process level monitoring of front-line workers in the production workshop, and timely collects and analyzes comprehensive information on production progress, employee performance, parking status, and work-in-progress. , To help managers obtain real-time production data from the system platform, analyze production bottlenecks and improve production efficiency, track the complete process of product production in each link and every process, such as receiving and dispatching, to prevent errors. At the same time, the electronic label establishes a connection channel for managers, company executives and front-line workers in the workshop. The production process data of each product is fed back to the managers at each level in real time and accurately, which greatly improves production efficiency, saves manpower, and Paper and communication time can improve the production efficiency and management decision-making ability of the enterprise.

The functions of using RFID automatic identification technology to realize production line management are:

1) The system automatically records which work orders each worker is doing during which time and how long it takes

2) Each process on the production line uses the RFID station reader to automatically complete the number of subsequent processes;

3) Employees can check their production records throughout the day through the self-service card swiping terminal;

4) Quality inspection: The way to improve the efficiency of quality inspection is to quickly identify the quality standard of the clothes on hand, and RFID combined with the display screen can meet this requirement. When the clothes are brought over, the reader at the bottom of the screen reads the clothes. The label immediately displays the clothing size requirements, various frontline requirements and other standards on the screen, so that the quality inspection work can be completed quickly and effectively.

5) The system real-time statistics and calculates the production progress of each group, each station, and each process, and provides the best and accurate production data for the manager’s worker deployment, improves work efficiency, and reduces the waste of human resources.

Automatic calculation of working hours, automatic output calculation

The RFID production line management system uses electronic work tickets instead of traditional paper work tickets, uses an RFID tag for each single product on the production line, and installs an RFID data collection terminal at each station. When a worker completes a job, the system automatically sends the information of the workpiece directly to the computer system through the RFID collection device, and the system automatically completes piece rate calculations and various production statistics.

Automatic tracking management to improve production efficiency

The system monitors the production status of each workshop, the whereabouts of all fabrics, and the completion status of each worker during the production process. It can understand the status of the order completion in real time, promote the work of the workers, and improve the production efficiency. Intelligent data collection to reduce human errors The system uses RFID technology to automatically collect data in the entire production process of production plan release, batching, cutting, sewing, etc., to avoid errors caused by human factors.

Efficient quality monitoring system

The source of the unqualified products can be traced, and the responsibility can be traced correctly, prompting workers to correct working attitudes and improve production quality. Cost-saving label content can be read and written, and can be reused, saving costs.

RFID technology tracks the entire production process, from the cutting machine to the parking space, to the embroidery to the button, to the outsourcing process, to the washing process, to the quality inspection and other links. It collects comprehensive and accurate production line information in real time, and through the real-time data Analysis, master the work progress and efficiency of the entire production line, thereby improving the response speed, shortening the production cycle, reducing costs, increasing profits and competitiveness. RFID technology is used in the garment production link to automatically identify and collect the production information of each link to the platform information server, establish RFID garment production information management, realize production task schedule control, production material tracking, and real-time monitoring and scheduling of production core links And other functions.

[ad_2]