RFID digital management system for production line of a shoe company in Guangdong

[ad_1]

Specific case

A shoe manufacturing enterprise in Guangdong belongs to a larger-scale shoe processing enterprise in Guangdong Province. The original production mode is the use of bar code mode to control and manage the production process. The problem encountered is that the workload and error probability of the bar code are relatively high. At present, with the upgrading and continuous expansion of enterprise production management, the company hopes to use our company’s RFID digitalization The solution of the production line management system solves the existing problems.

solution:

According to the specific situation of the company, Zhuhai Shenwang Technology puts forward the plan of Zhuhai Shenwang Technology’s RFID production line management system. The whole plan is based on the characteristics of RFID and the actual production of the company to ensure that the company better manages the production process. The specific description is as follows:

1. Design idea: The system is composed of RFID technology combined with computer equipment and ERP system. The RFID card reader placed at the scanning point can obtain the field data in time by reading the RFID card and import it into the ERP system. Through statistics and analysis of on-site data, the system can simultaneously understand the current production situation, discover and deal with abnormalities in time. A series of complicated tasks such as manual repetition of points and statistical data can be saved, human errors can also be reduced, and information can be quickly and efficiently fed back to the user’s information processing system.

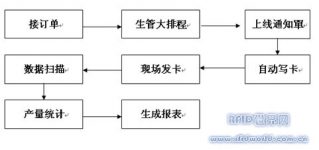

2. Optimized production process:

3. Distribution map of RFID data collection points: (the red is the collection point)

4. Data collection process setting:

5. RFID data exchange process setting:

6. RFID system program interface (you can see the production progress of each instruction)

7. Actual photos on site:

Enterprise Evaluation:

The RFID system of Zhuhai Shenwang Technology is a system that can be used on site. A production line requires only a few people to understand computer knowledge, and the operation is not complicated. It is easy to maintain and does not require professional and technical personnel to operate. Although the RFID system is a new thing, it is rarely used in the manufacturing industry, and it has no precedent in the footwear industry at home and abroad. Zhuhai Shenwang Software Technology Co., Ltd. has received strong support from the company. It can be used in production flow. Automatic control is realized online, and data can be fed back in time, which greatly improves production efficiency, improves production methods, and saves costs. Thanks to Shenwang Technology for the realization of a high-stability RFID digital production management system for our company. I hope that the RFID digital warehouse asset management system currently being designed and implemented will be more powerful. Finally, I hope that the products of Zhuhai Shenwang Software Technology Co., Ltd. can be produced in other domestic products. More widely used in the industry!

Highlights of this application case:

1. The first large-scale application of RFID identification technology in a large-scale production industry assembly line in China.

2. Through the self-developed software and the enterprise’s ERP connection, the implementation of monitoring production progress, improving customer order management capabilities, and improving the efficiency of production enterprises.

3. The warehousing RFID project under implementation can fully realize the precise complete production link of the industrial-grade production line, and realize the seamless connection of each link from procurement-storage-delivery-sub-process processing-finished product warehousing-sales.

4. Research and develop a fully automatic dedicated RFID card issuing, reading and writing integrated machine,

[ad_2]