RFID gradually began to be applied to the discrete manufacturing industry

[ad_1]

With the rapid economic development, the development of the manufacturing industry has been driven, and the development of unmanned, intelligent, and automated production lines has attracted a lot of attention. RFID technology carries out large-scale and batch production, which solves the urgent need for fast and high-quality production. Fully automatic production line production realizes automatic data management, information management, and real-time monitoring and management. RFID production line assembly line application, mainly through the RFID reader equipment installed in the production line station or suitable position, reading the RFID electronic tags installed on the pallet, or the product for data collection, reading, management and control, to complete a series of production Situation management.

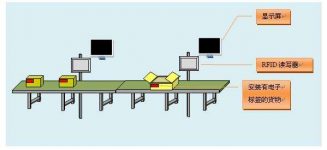

RFID has gradually begun to be applied to the discrete manufacturing industry. Compared with the currently widely used barcode technology, RFID electronic tags can be non-contact, wireless long-distance collection, strong penetration, high-speed movement, and store more data , It can be used in harsh environments and other advantages. The goal of production line visualization is to enable enterprise management to discover in-process production and production line operation status in real time. The plan is mainly composed of assembly line, RFID data collection system, work-in-progress and workstations. Work-in-progress moves on the assembly line. After reaching the workstation, workers remove the parts for assembly, and then put it back on the return line until everything is completed. In the process, the RFID data acquisition system mainly includes RFID readers, and each work-in-process is bound to an RFID electronic tag.

Give full play to the technical advantages of RFID and adopt RFID technology on the production line. It is not a completely new set of RFID-based production management system. Instead, RFID information is integrated with the existing bar code-based production management system to organically apply RFID. Incorporated into the overall structure of enterprise informatization. Use RFID, barcode, and sensors to collect real-time data on the production line, and transmit the read data to the upper equipment (controller, computer) through the network (wired or wireless). To manage loose sensors requires a new management mechanism that can automatically discover and organize the network, deploy RFID readers, and establish a reader network connection to solve the problems of planning, optimization and control of the reader network. The RFID electronic tags on the items, combined with the RFID readers of the network, each identification means the tracking of the items.

Not only that, the RFID system can also provide a variety of applications and services, including: production line status monitoring, employee behavior monitoring, production management, quality management and tracking, material management, job scheduling, on-site operation guidance, and real-time uploading of production data. The entire network architecture must provide the function of information tracking. According to the identification code of the product, all the information of the product and the information of each flow point can be listed. In order to ensure that the tracking information is complete and the information chain can be queried in real time, the information chain backup function is provided, so that the tracking information can be found even if there is a little interruption.

RFID is perfectly combined with existing manufacturing information systems such as ERP, CRM, etc., to establish a stronger information chain as the basis of intelligent manufacturing, allowing RFID technology to deliver accurate automated data collection in a timely and accurate time, thereby improving assets Utilization, productivity enhancement, various online measurements, and support for quality control. RFID technology will bring huge benefits to companies with a sense of modernization, diversification, and high-demand corporate management.

[ad_2]