RFID technology creates integrated intelligent production line management

[ad_1]

Industrial intelligence has always attracted much attention. For manufacturers, it is very important for manufacturers to provide timely and accurate feedback on all aspects of the production line. With the rapid development of RFID technology, intelligent manufacturing production combines RFID technology and existing IT systems to establish a real-time management system for intelligent and digital production lines to optimize production and use resources more rationally, thereby increasing production capacity , Asset utilization and high-quality control, let production create greater benefits. RFID technology creates integrated intelligent production line management.

RFID is entering the core of the manufacturing process. By gradually adopting RFID technology at the workshop level, manufacturers can directly and uninterruptedly obtain information captured from RFID and link to the existing, proven and industrially enhanced control system infrastructure, and coordinate with the supply chain equipped with RFID functions. There is no need to update the existing manufacturing execution system (MES) and manufacturing information system (MIS) to send accurate and reliable real-time information streams, thereby creating added value, increasing productivity and greatly saving investment.

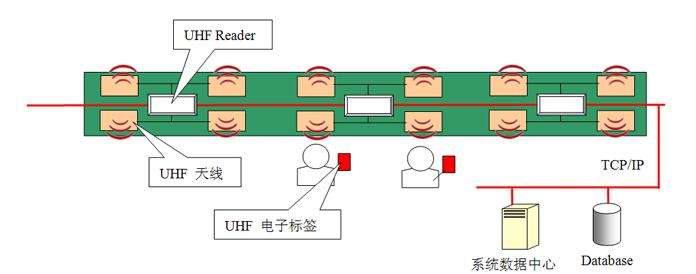

RFID technology production line management is the application of advanced RFID automatic identification technology in the production line, product transfer area and temporary storage warehouse, using repeatable RFID electronic tags, each RFID electronic tag has a unique ID number, and can read and write data Area, write product information into RFID electronic tags, install readers at the offline stations of the production line and warehouse entrances, read and write tag information through RFID, automatically write and collect product information at various locations, and share data with other MES systems Information and information are displayed on the screen at the same time, prompting the production line operator, so as to carry out the whole process tracking management of the products that need to be processed from the offline to the warehouse transfer, temporary storage, and then on-line production, so as to ensure the batch of goods between the production lines. Corresponding to the secondary box number, each production line can complete the production task without error, and record important information in the production process, which can provide basic data services for future quality information traceability.

1. Station management, generally used in piece-counting production occasions, employees use their ID cards to swipe their cards to start work, read the RFID electronic tags on the products to record the information of the processed products, the main function is to record employee attendance and work quantity information; record product information, Provide dynamic progress information, and discover production line capacity bottlenecks through data analysis, and provide a basis for flexible production.

2. Automated production line management. In automated production line applications, install RFID electronic tags on products or carriers, and use production line RFID readers to read product information in order to provide processing attributes for automated processing.

3. The production line track supermarket management, the RFID reader is installed in the feeding area of the production line to read the information of the material box or the workpiece, which provides a basis for rapid replenishment and improves production efficiency.

4. RFID management of fluent rack, install RFID electronic tag reader and small display screen in each fluent rack, automatically record the batch and quantity of feeding, and provide feeding forecast information in time, and the light can prompt the feeding port when feeding And display the batch material name and other information.

RFID’s process management solves the dependence of process management on labor. The processes of the entire manufacturing process are more accurate and convenient, and the processes of the products can be tracked and traced. Once there is a problem with any work-in-progress, the source of the problem can be quickly found and solved immediately. Compared with manual work, it greatly improves efficiency.

RFID technology automatically collects all professional links in production, forms real-time information collection and transmission, and makes system statistics convenient, timely and accurate. Improve the work efficiency of the production process, create visualization of cost control management, and product logistics monitoring and management.

[ad_2]