RFID technology implements fully automatic and intelligent management and control of electroplating production line

[ad_1]

With the development of science and technology, the management of the electroplating production line is constantly changing. The workers on the electroplating production line must manually set the working parameters of the equipment used in the electroplating process by observing the types of hangers and parts and other information. To ensure that the process parameters of the parts to be processed are accurate. However, manual settings will not only affect the production efficiency of the production line, but also are extremely prone to errors; the life of the hanger of the general production line in the electroplating process is limited, and it may require multiple maintenance during the entire use process. The hanger needs to be scrapped, otherwise it will cause defects in the electroplating process of the parts. The application of RFID technology in the electroplating production line realizes fully automatic and intelligent management, making the production process of the electroplating production line more flexible, refined and intelligent.

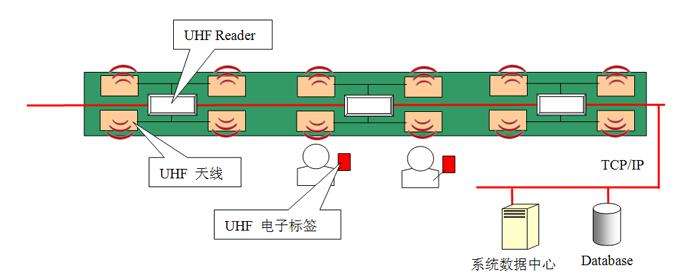

RFID technology can be called RFID radio frequency identification technology. It is mainly the work between the RFID reader and the RFID electronic tag, and data communication can achieve data exchange and then identification. It is mainly used in fields such as RFID automated production, manufacturing, and intelligent parking management.

RFID automatic intelligent electroplating production management standardization

Each product and each component has its own fixed electroplating process. A flow chart of each electroplating process for each product is made. There will be no confusion leading to the wrong plating process, and there will be no differences in the electroplating process due to similar processes. Some necessary processes are missing. All products are affixed with their own independent labels, so as to realize the independent monitoring and management of the products and achieve the standardization of production management.

Production line production automation

All products are affixed with their own RFID electronic tags, and the data is read through the production line card reader to realize the production line’s working status information, process conditions, product numbers, product parameters, part names, models, specifications, each piece quantity, and driving Real-time dynamic information of the entire production line, such as status, enables accurate query of Ge Gongwen, and improves production efficiency.

Quality management standardization

According to RFID identification management, the operation steps of each process of each product are quantified, and each action is specified to avoid problems and avoid the impact of operator errors.

The standardized implementation of RFID technology automatic intelligent electroplating production management is to automatically collect the information of the racks and parts in the electroplating process, and provide an information basis for the electroplating process related equipment; through the combination of information technology with sensor technology, automation technology and RFID technology, the electroplating production line is realized The whole process is automated, realizing the real integration of the two technologies. RFID technology realizes the whole life cycle management of the hanger, greatly reduces the product failure rate, continuously optimizes the production efficiency of the enterprise, reduces the labor intensity, and reduces the mistakes in the selection of manual process parameters; it improves the company’s all-round production and warehousing Information management level.

[ad_2]