See how RFID UHF technology leads clothing management to new heights

[ad_1]

For a long time, the application of RFID electronic tags in the domestic retail industry is also in full swing due to their better security, large data flow, long service life, and convenient and quick reading. More than 60% of the products sold by cosmetics and jewelry retailers in Europe and the United States carry RFID electronic tags. “In the past three to five years, the RFID tag antennas used in clothing retail, such as electronic jewelry tags, RFID clothing tags, etc., have been our main business performance, starting from Messi, to Decathlon, to Uniqlo, to Hailan House, especially from After Uniqlo’s promotion and application, the retail application of RFID technology has been nearly 90% in the past three years,” an industry insider said. The use of RFID technology can realize functions such as full-life tracking, efficiency improvement and intelligent anti-theft, and can solve the current problems faced by clothing management.

1. High-quality logistics, optimized supply chain management

When shipping the warehouse, use RFID equipment to quickly scan the goods, check the scanning results and the shipping notice, generate and print the shipping list of each box of goods, or the batch of shipping lists, and record each RFID electronic in the database Product attributes and product flow information such as the delivery time, whereabouts of the goods, and the agent number of the goods associated with the label. Realize the full-life tracking of commodities and the standardization of clothing logistics operations, shorten the operation process and operation time, and reduce labor costs.

At the same time, the use of RFID can minimize the delivery error rate. The delivery error mainly refers to the shortage of the original box and the error of the packing box. Both of these problems can be minimized by using RFID technology.

2. Efficient warehouse receipt, delivery, and inventory operations

One of the most important tasks in the sample warehouse is to ensure that the booked quantity is consistent with the actual quantity. When the warehouse picks goods or the store counts, the RFID inventory stick can be used to quickly pick the target goods according to the order to avoid wrong picking and missed inspection. There is no need to perform one-by-one operations during inventory, and efficient inventory can be achieved. Using RFID technology to overcome the defects of large number of samples and time-consuming inventory, complete the inventory easily and quickly, the operation is simple and easy to learn, it can easily achieve the accuracy of the goods receipt record and the automation of the delivery and distribution, so that the inventory will not be counted. There are omissions and losses.

At the same time, the sample entry and return information can be recorded to everyone through the sample management system, and daily and monthly data statistics can be performed. At the same time, it can be connected with the ERP system to improve the sample management system and lean the enterprise. The management of sample clothes makes full use of big data and cloud platform to realize the transparency of sample clothes information.

3. Out of stock alarm, timely replenishment

Through the RFID sample management system, when a product shortage occurs in the sample warehouse, it can not only automatically alert the alarm, but also subdivide the details of product composition such as model type, color, size, etc., to truly achieve refined management.

4. Label binding products, effective anti-counterfeiting

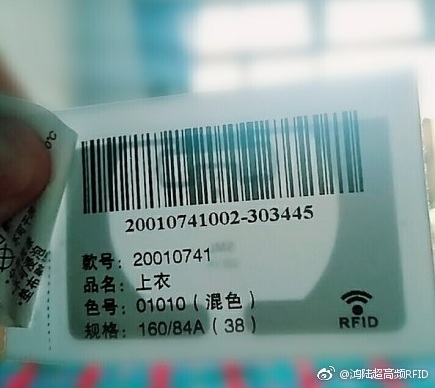

In the production process of clothing, the important attributes of a single piece of clothing, such as name, grade, article number, model, fabric, lining, washing method, execution standard, product number, inspector number, etc., are written into the corresponding RFID electronic tag. And attach the electronic tag to the clothing.

The attachment method of the electronic tag can be: implanted in the clothing, made into a nameplate or tag, or adopts a recyclable anti-theft hard tag, etc. Each piece of clothing is given a unique electronic tag identification that is difficult to forge, which can effectively avoid counterfeiting and well solve the problem of clothing anti-counterfeiting.

5. Intelligent anti-theft, quick stop loss

The UHF RFID reader has a relay output function inside, that is, when the UHF RFID reader reads a tag or a tag with a specific format, the UHF RFID reader will close the relay, thereby triggering the external relay to close, and Start the alarm or alarm indicator to alarm. There are several situations for RFID tag anti-theft: the RFID tag of the clothing store needs to be recycled. In this case, the reader installed at the door of the clothing only needs to read the tag to trigger an external alarm Alarm. The RFID tags of the clothing store are not recycled. The clothing store can use the UHF RFID reader to rewrite the tags on the clothing that the customer is about to buy, and define a byte of data. When the byte is 0, it means that it has not been purchased, and it is rewritten as 1:00 means the purchase has been made. When the reader at the door reads an unrewritten tag, it triggers an external alarm to alarm, and when it reads a rewritten tag, it does not trigger the external alarm to alarm. This can solve the misunderstanding caused by tag reading and writing.

6. Statistics of slow-moving products to maximize profits

The backlog of products in the clothing industry is a very headache. The unsalable products are counted through the RFID sample management system, and the stay time of each product (subdivided into model, color, size) in the warehouse can be quickly discovered which products are unsalable. , After the season, managers can quickly make price reduction decisions or exchanges, speeding up product sales and capital turnover.

At present, many apparel brands are facing challenges such as low supply chain efficiency, rising labor costs, and blurred market trends. Faced with large-scale collection and delivery, returns, inventory, and sorting tasks, the management model of using barcode recognition technology is time-consuming, laborious, and labor-intensive. Fee venue. And RFID technology can just improve these problems, can realize automated production, warehousing and logistics management, brand management, channel management, and bring management convenience to the clothing industry.

[ad_2]