Spanish children’s clothing manufacturer uses EPC Gen 2 label to track single-product clothing

[ad_1]

Boboli, a Spanish children’s clothing manufacturer and retailer, is preparing to launch a test project that uses RFID to identify individual pieces of clothing and evaluate its commercial value. The company particularly hopes to increase the speed of receiving goods while also increasing the amount of goods the company handles and sends to retail stores.

The first phase of the project is planned to start at the end of August 2008, with a three-month cycle, focusing on improving the efficiency and accuracy of the goods receiving and shipping process at the Boboli Barcelona main distribution center, and speeding up the distribution center to send clothing to various retail stores. The speed of the shop. A clothing supplier will join this phase of testing, and the supplier will supply 10% of the goods in the distribution center.

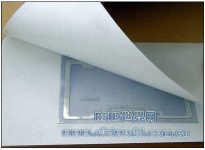

The supplier will attach a use tag containing Tagsys RapidTRAK RFID UHF passive EPC Gen 2 inlays to each item. The inlay is pre-programmed with an EPC code, which includes the style, size information and a unique identification code of the garment. At the distribution center, the boxes loaded with labeled clothing will be placed on a conveyor belt and flow past a channel-type Tagsys reader. The reader antenna is installed around the conveyor belt. When the cargo box passes through the channel, the antenna reads the tags in the cargo box from three directions (top and sides).

Use tag with Tagsys RapidTRAK RFID UHF passive EPC Gen 2 inlay

The label is encoded with EPC code, including clothing style, size information and a unique identification code

Cargo boxes loaded with labelled garments flow through a channel-type Tagsys reader

The reader will filter and transmit the EPC read data to the Tagsys e-connectware software. The software then compares these EPC codes with the delivery notice received in advance by the distribution center to ensure the integrity of the received goods. After all the goods labels are read, if the reader detects a shortage or excess, e-connectware will send an alert to the relevant personnel in the distribution center.

According to Didier Mattalia, Tagsys’ head of apparel sales, Boboli’s three-month test is not a technical test. “The technology has been proven,” he said. Boboli has tested the channel reader and the reader works well. This is not a test to decide whether to use an RFID system, but rather a confirmation of the advantages of the RFID system.

By using an RFID system instead of traditional barcode scanning to automate the delivery of goods in the distribution center, Boboli hopes to improve the accuracy of inventory and speed up the delivery of products to retail stores. This can avoid the phenomenon of empty containers, help retail stores maintain or increase sales, or sell seasonal goods or new products according to arrangements. The company eventually plans to install RFID readers in the store, so that employees can use RFID tags to quickly process the goods sent from the distribution center, perform inventory and locate special items.

Boboli hopes that when the three-month test is over, there will be more suppliers supplying labeled clothing, Mattalia said, and plans to implement a 50% product labeling plan by the end of 2009.

According to Mattalia, the channel reader can accurately read 18,000 labeled items per hour.

Currently, Avery Dennison is responsible for packaging Tagsys RapidTRAK inlays into clothing labels. Tagsys designed the system in cooperation with Cetemmsa, a Spanish technology integrator.

Boboli produces more than 2 million pieces of clothing each year and sells them to hundreds of stores, including the company’s 30 stores in Europe, the Middle East, Asia and the United States.

[ad_2]