Suzhou Weixin Electronic RFID Project

[ad_1]

1: Use process

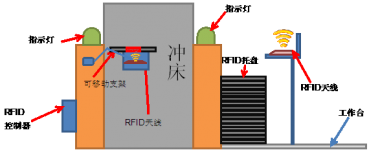

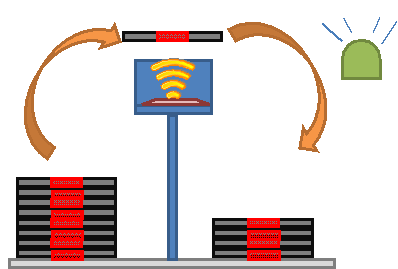

This equipment is used in the punching production line. During the punching process, the worker removes the pallet with the circuit board on table A and passes through the antenna. The antenna can read the RFID tag attached to the side of the pallet. After the stamping is completed, the circuit board will be moved to another tray. When this tray is placed on table B, the RFID tag attached to the side of the tray will also be read through the antenna on the other side. In the process again, it is realized that the circuit board establishes the associated information of the two pallets in the pallet transfer. Realize the automatic entry of related information (no human intervention). Do not add new operating links for operating workers, and do not affect workers’ unit working hours. As shown in the figure:

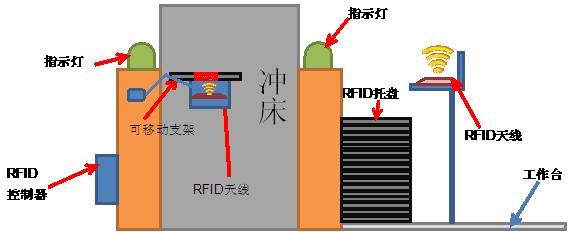

2: The installation method is shown in the figure:

Installation location: placed on the workbench to the left of the punch staff.

There are counterweights or rivets under the bracket. The bracket with counterweight can be directly placed on the workbench, and the bracket with rivets will be installed on the tabletop using expansion bolts. The bracket extends a long arm, and there is a bracket for installing the antenna on the long arm.

3: The purpose of the RFID device on the customer

With the globalization of the economy, traditional processing and manufacturing industries, especially the electronics industry, have higher and higher single-product manufacturing costs and lower and lower processing profits. In order to improve the overall profit rate of the enterprise, optimize the enterprise management process, and use information Chemical transformation to improve production efficiency has become one of the effective means.

4: Benefits for customers

Using this set of RFID production line management equipment, customers can realize real-time information management, flexible manufacturing management, and accurate tracking and tracing of the punch production line. Improve the customer’s automated production level, production and management efficiency, make production management more flexible, and create more profits for the customer’s enterprise.

5: Difficulties and highlights

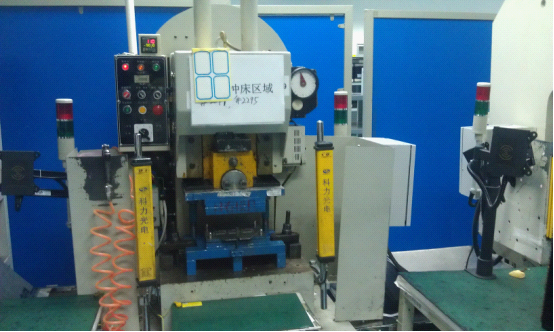

The equipment is used in the press production line, the site environment is complex, the space is small, and the equipment is crowded. The reader and the antenna are very close to the punch, and they are susceptible to strong electricity and magnetic interference from the punch.

The antenna specially designed and manufactured by our company for this project can perfectly meet the needs of customers and minimize the impact of the on-site environment. Ensure that there is no misreading without losing sensitivity and no missed readings. The effective reading distance of the front of the antenna is 10CM, and the side and back can ensure that it will not be read beyond 1CM to avoid misreading. Industrial-grade protective shell, dustproof and waterproof.

6: Attach photos of the project site

figure 1

figure 2

image 3

Highlights of this application case:

Due to the on-site environment, the customer’s needs are contrary to the conventional needs. In the past, RFID equipment needed to read as far as possible, and the wider the range, the better. But in this project, the reading distance required by the customer is only 10cm from the front of the antenna, and the reading range is accurate to 1cm around the antenna.

The antenna specially designed and manufactured by our company for this project can perfectly meet the needs of customers. The reading distance from the front of the antenna is only 10cm, and the reading range is accurate to within 1cm around the antenna, ensuring that there is no misreading without loss of sensitivity, and no missed reading.

[ad_2]