Wireless control system of textile printing and dyeing assembly line based on ZigBee

[ad_1]

Wireless control system of textile printing and dyeing assembly line based on ZigBee

Client A printing and dyeing factory in Shenzhen

Market demand At present, the double-chain synchronous control of stenter setting machines in most printing and dyeing textile industry assembly lines uses a motor to control the mechanical long-axis transmission mode, but after a long period of operation, the main chain caused by mechanical wear cannot be avoided. There is a weft skew between them, which cannot be corrected. Therefore, the new stenter setting machine uses double motors to drive the double chains separately. Multivariate synchronous assembly line automation control has already eliminated the traditional manual control, and the control using industrial Ethernet as the transmission medium requires the whole plant to be wired, which is very troublesome. Helicomm uses ZigBee technology to develop a wireless control system for the textile printing and dyeing assembly line. The central end uses the ZigBee wireless mesh network to transmit instructions to the PLC to realize multi-unit synchronous control of the printing and dyeing assembly line. The system is simple to set up and wireless throughout.

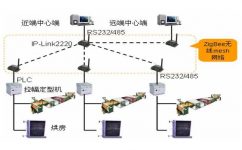

The solution is shown in the figure. This system uses the IP-Link2220 wireless data transmission terminal independently developed by Helicomm. The ZigBee wireless mesh network set up in the production workshop is the transmission medium. The system terminal uses IP-Link2220, PLC, and textile printing and dyeing assembly lines to connect. The central end uses IP-Link2220 to connect with the PC through the serial port. The central PC controls the remote PLC through the ZigBee wireless mesh network, and then controls the multi-unit synchronous operation of the entire stenter setting machine, as well as the frequency conversion drive and amplitude modulation drive of the circulating fan and exhaust fan.

The system is easy to maintain and supports remote wireless firmware update and configuration. The IP-Link2220 wireless data transmission terminal has an industrial standard RS232/485 interface; 16 communication channels are flexibly selected; CSMA/CA anti-collision mechanism to avoid the occurrence of packet loss caused by multi-point high-speed data transmission, making the system more stable and accurate.

Why choose Helicomm

1. Advanced wireless Mesh network, network routing can reach at least 20 hops, no communication cost.

2. Adopt ZigBee technology with low cost and low power consumption.

3. The product has passed FCC, CE and other international safety certifications.

4. With many years of R&D and industry experience, independent core technology, and customization capabilities based on the standard ZigBee.

[ad_2]