Avery Dennison becomes the exclusive RFID technology partner of Brazilian beauty group Grupo Boticario

[ad_1]

As the second largest cosmetics company in Brazil, Grupo Boticario has the world’s largest cosmetics franchise network. Its sales business covers cosmetics, perfumes, skin care products, etc., and operates a business that includes branded retail stores, online channels, direct sales and other retail partners Large-scale integrated supply chain.

As we all know, supply chain management has always been a huge challenge for the beauty industry, especially for brands like Grupo Boticário that have achieved double-digit growth in total sales in Latin America and the United States. Common problems include low inventory visibility, stock out, and The high rate of loss of goods, slow product circulation and inaccurate demand forecasts, etc. As the supply chain becomes more and more large to cope with the continuous growth of business, Grupo Boticario decided to carry out the digital transformation of the supply chain management system to achieve end-to-end item-level product traceability. Ernst & Young was entrusted by it to provide the best technical matching consultation for this project.

After evaluating options such as infrared, ultrasound, video, and two-dimensional barcode recognition systems, Ernst & Young and Grupo Boticario agreed that RFID is the best supporting technology. With the multi-party collaboration and support of the company’s human resources department, logistics department, operation department and leadership, the project team finally selected 10 application scenarios that prioritize the use of RFID, and started a six-month period of data from the third quarter of 2018. test.

After comprehensively evaluating various factors, the decision makers chose Avery Dennison as their partner. Avery Dennison has specially designed the attributes of metal packaging and liquid products in the beauty industry to overcome technical difficulties, so that RFID tags can be quickly and accurately read on metal or liquid-containing packaging, which not only achieves Single-item-level recognition in denser beauty sales scenarios, and when the product leaves the distribution center and enters the store receiving link, it can also be applied to carton recognition.

Before the start of the test, the project team created an independent, RFID-based system for testing: the distribution center and store programs run with the middleware of the Grupo Boticario server, and all the distribution center processes and store operations are also in the same Middleware. Fixed readers are used to scan RFID tags located in the distribution center, store clerks use handheld readers for store inventory tracking, and flat-panel readers are used for checkout counters. The above tests are in compliance with the GS1 EPC UHF standard.

The top priority of the project is to locate the label position on more than 2,000 inventory items and multi-category products. Label testing is carried out under different conditions, and at the same time, the packaging designer of Grupo Boticario works with Grupo Boticario to ensure the visual beauty of the packaging without affecting the performance of the label. So far, more than 1.2 million single products have been tested.

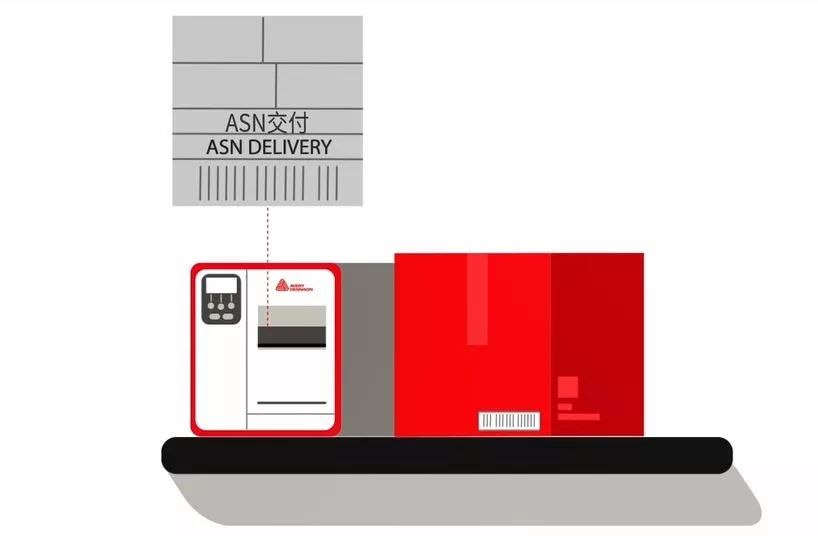

In this test, RFID tags were applied before the goods were shipped from Grupo Boticario’s distribution center. The staff of the distribution center first scans the SKU number of each item in the carton and enters the information of each delivery box. Then use Avery Dennison ADT1 printer to print out the RFID label with the SKU number of each product, and paste it on each product and delivery box. Finally, the staff inspected each carton again before shipment to ensure that they were affixed with RFID tags with the product SKU number. (As part of the test, the project team also tested whether the packaging line of the Grupo Boticario factory, after the products are packaged and attached with RFID tags, can also help the staff to quickly read the cartons in a few seconds, just like in the distribution center. Hundreds of items in the store.)

In the end, the cartons were distributed to four test shops: two retail shops and two wholesale shops (sales direct sales points). In these stores, RFID systems are used to improve the five major processes: receiving, replenishment, inventory counting, checkout and demand forecasting.

·One scan can get the whole box of goods information covering up to 400 single products, receiving faster and more accurate

The database of the store divides the goods into “warehouse goods” and “shelf goods”, so that the demand for replenishment on the shelf is clear at a glance, and it becomes more convenient to track the movement of goods from the warehouse to the shelf

·Promote sales and reduce waste: RFID warning messages for products that are about to expire can enable shop assistants to take measures such as discount sales as soon as possible

·At the checkout counter, all purchased goods can be scanned and read at one time

·The demand plan maker can replenish goods in time and make sales forecasts based on comprehensive and accurate data

The test results exceeded expectations. It is expected that the 50% reduction in out-of-stock rate has actually achieved a 78%-97% reduction in participating stores. The use of RFID has helped to find more than 50% of the products that were lost in the original system. At the same time, the man-hours spent on inventory management have been reduced by 14%, and the store’s income has increased a lot compared to when RFID was not used. It can be seen that RFID is indeed effective in helping stores improve inventory accuracy and eliminate stock-outs.

Avery Dennison’s global director of market development Bob Pernice said, “The beauty industry is discovering the advantages that RFID has already played in the apparel industry-item-level labeling solutions have greatly improved inventory accuracy and promoted revenue growth. “, he said, “The average inventory distortion rate in the apparel industry is 35%, while in the beauty industry, this figure is as high as 50%. This is because beauty brands and retailers operate more single-stock items (SKU). In the self-service shopping environment, the inventory depth is usually insufficient, and the product loss rate in the beauty industry is also higher. In addition, the brand loyalty of beauty consumers is usually high. When a certain category is out of stock, it is generally not considered to use alternative brands For example, a certain dark lipstick or eye shadow is often out of stock, and the store system and shop assistants usually cannot notice in real time, which will directly lead to the loss of sales and customers, especially when the retailer associates the inventory data of the physical store with e-commerce , The negative effects are more obvious.”

“Confidence comes from cooperation with global technology leaders”-Grupo Boticario

Avery Dennison has leading RFID technology and forward-looking industry solutions. Its technical development for the uniqueness of the beauty industry has given Grupo Boticario’s management great confidence.

[ad_2]