Supermarket intelligent warehouse rack management application based on RFID technology

[ad_1]

The combination of technology with the Internet and communication technology can be applied to many industries such as logistics, manufacturing, and public information services. RFID has also been widely used in the retail industry, and it is making the fastest progress. For the warehouse management of large supermarkets, an intelligent warehouse management system based on RFID is proposed. Attach the radio frequency card to the cargo, and all cargo information is stored in the central computer in the warehouse, and the information related to the cargo can be found in the computer. Readers and antennas are placed at the entrance and exit of the warehouse, and wireless relay terminals are arranged on demand to form a wireless sensor network. When the goods enter and exit the warehouse, the reader placed at the import and export will read the information of the radio frequency card attached to the goods and transmit it to the management center through the wireless sensor network, so that the management center can understand the in and out of the goods in real time, and grasp the goods For the sales situation of the company, timely adjust the variety and quantity of the purchase. It helps to solve the two biggest problems in the retail industry: out of stock and wastage. At the same time, consumers don’t have to line up at the checkout counter, and directly push the cart full of goods to go out. The computer at the door automatically prints the shopping list, which improves the shopping environment and enhances the competitiveness of the enterprise.

1

Introduction to Radio Frequency Identification Technology (RFID)

RFID technology is a non-contact automatic identification technology that uses radio waves to communicate. The radio frequency identification system generally consists of 3 parts: transponder, reader and background database application software. The basic principle is to carry out data communication through electromagnetic coupling or inductive coupling between the reader and the tag attached to the object to achieve non-contact automatic identification of the tag item. The reader sends instructions to the antenna, and the antenna sends radio waves to “scan” the radio frequency tag. After receiving the signal, the radio frequency tag returns the data information to the form of radio waves, which is received by the antenna and decoded into data that can be used by the computer.

2

The overall frame design of the system

Aiming at the characteristics of intelligent warehouse rack management in large supermarkets, the system mainly includes:

The interaction of RFID identification system, wireless sensor network, RFID identification system and wireless terminal.

2. 1 RFID radio frequency identification system

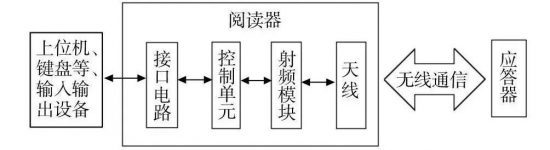

The main function of the reader is to read and write data to the transponder through the antenna and communicate with the upper computer. It generally contains a radio frequency module, a control unit and a coupling element connected to the transponder. In addition, the reader has an additional interface to transfer the obtained data to another system.

The reader hardware system is mainly composed of 4 parts: interface circuit, control unit, radio frequency module, antenna, as shown in Figure 1. The upper computer is connected with the reader control unit through the interface circuit, and sends commands such as read/write card to the control unit. Receive data and operation reports from the control module. The control unit is connected with the radio frequency module, and the main program running on the control unit controls the operation of the radio frequency module according to specific conditions. The radio frequency module modulates the data and sends it to the transponder through the antenna, and demodulates the transponder return signal received from the antenna.

Figure 1 Block diagram of the hardware system

The radio frequency module of the reader adopts the FM1725 contactless IC card chip of Fudan Microelectronics Company, which completes the functions of data modulation and demodulation, and rectifies and transmits the radio frequency modulation signal. The transmitter part of the FM1725 chip can directly drive the antenna at a short operating distance without adding an active circuit. At the same time, the receiver part provides a reliable demodulation and decoding circuit. Its digital processing part converts parallel data into serial, supports checking the generated frames, generating and checking parity and CRC, as well as bit encoding and processing. In addition, FM1725 also provides an SPI compatible interface, and its parallel interface can be directly connected to an 8-bit MCU.

The control unit of the reader adopts the high-performance 8-bit single-chip AT 89S52 produced by ATMEL. It is mainly responsible for running the program of reading and writing the card, providing the control signal of the FM1725 chip, and completing the data communication with the upper computer or the network through the RS232 interface. The single-chip microcomputer contains 8K bytes of Flash read-only program memory, and its space is large enough to write programs that drive and control the FM1725 radio frequency chip. There is no need to connect other external storage devices, which simplifies circuit design and improves circuit reliability.

The radio frequency card adopts the passive Mifar e standard IC card MF1 IC S50. There is 8K EEPROM in the card. It is the storage carrier of data. The data is read and written through the antenna of the reader.

The basic operation process is shown in Figure 2. The user first writes information into the MF1 IC S50 card through the reader. When the MF1IC S50 card enters the working range of the reader’s antenna, the card is activated and the reader sends a read data signal to the card. The card sends the data specified in the storage unit to the reader through the antenna according to the received data signal, and the reader sends the data to the host computer or network through the RS232 interface.

Figure 2 Basic operation process

2. 2 Wireless Sensor Network

The wireless sensor network is composed of many wireless sensor network nodes deployed in the monitoring area. Its purpose is to cooperatively perceive, collect and process the information of the sensing objects in the geographic area covered by the sensor network, and pass it to the observer through Ad ho c. By.

2. 2. 1 Sensor node

Wireless sensor network nodes mainly complete data collection, processing and transmission functions, and are usually composed of 4 units. See Figure 3.

Figure 3 The composition of wireless sensor network nodes.

In the wireless sensor network node, the micro-control unit uses TI’s MSP430F19 type single-chip microcomputer, and the wireless transmission unit uses the IA4420 chip from I nteg ration Associates.

1) Micro control unit. TI’s MSP430 series is a 16-bit hybrid single-chip microcomputer with reduced instruction set and ultra-low power consumption. In the wireless sensor node.

2) Wireless transmission unit. The core chip used in the wireless transmission unit is IA4420. It is a programmable, low-power, multi-channel frequency shift keying (FSK) full-duplex radio frequency transceiver chip launched by Integ rat ion Asso ciates.

IA4420 can work in the ISM (industrial, scientific, medical) frequency bands, which are 315, 433, 868 and 915MH z. The operating voltage of the chip is 2.2~5.4V, and it adopts low power consumption mode, and the standby current is 0. 3uA, FSK modulation mode is adopted, the transmit power is adjustable from 5 to 8 dBm, and the measured transmission distance in an open outdoor area is more than 200m.

2. 2. 2 Wireless Sensor Network Protocol

The media access control protocol is abbreviated as the MAC protocol, which is in the bottom part of the wireless sensor network protocol to solve the problem of how nodes in the wireless sensor network share media to ensure satisfactory network performance.

The MAC protocol has a great impact on the performance of wireless sensor networks. It is one of the key network protocols to ensure the efficient communication of wireless sensor networks. The performance of sensor networks, such as throughput and delay performance, depends entirely on the adopted M AC protocol. Cellular phone network and Ad-H oc are the current mainstream wireless network technologies, but their respective MAC protocols are not suitable for wireless sensor networks. The media access control in GSM and CDMA is mainly concerned with how to meet the user’s Qo S requirements and save bandwidth resources. Power consumption is second. Ad-H oc network considers how to establish links between nodes in a highly mobile environment, while taking into account certain Qo S requirements, and power consumption is not its primary concern. The primary consideration for the MAC protocol of wireless sensor networks is to save energy. This means that the MAC protocol of the traditional network is not suitable for wireless sensor networks, and a new MAC protocol suitable for wireless sensor networks needs to be proposed.

Aiming at the application of the IA4420 chip in wireless sensor networks, Integration has proposed a new MAC layer protocol-the protocol framework of the EZMac protocol.

EZMac is a M AC layer protocol based on the C language. It provides a simple physical layer interface between nodes for the application design of wireless transceivers, and manages the transmission of signals and the transmission of related data packets from the sender to the output end.

The data packet of EZMac is small and supports data transmission using the internal baud rate generator of the transceiver chip. The state machine action of EZMac is determined by a set of parameters stored in different registers. The MAC engine supports 4 basic modes: sleep, idle, transmission and reception. The sleep mode consumes the least energy, followed by the idle mode, and the transmission mode consumes the most energy. These 4 modes can be realized through 9 basic states. The 9 states are: sleep, wake up, idle, detect DQD (data quality detection), receive packet, packet valid, listen, transmit packet, transmit information Mistake. The state transition flow chart of EZMac is shown in Figure 4.

Figure 4 EZMac state transition flow chart

2. 3 Interaction between wireless terminal and RFID system

Mainly, the reader in the RFID system reads the information and sends it to the wireless terminal, and the wireless terminal transmits it to the central computer through the wireless sensor network.

3

Conclusion

According to the technical characteristics of RFID, this article applies RFID to the intelligent warehouse management of supermarkets; and combines RFID technology with wireless sensor networks. As a sensor node of the wireless sensor network, the RFID system, together with other sensor nodes, such as fire and anti-theft sensors, can form a comprehensive intelligent supermarket monitoring system. This provides the possibility for the supermarket shelf management to further reduce the additional cost of goods as much as possible, and increases the supermarket’s competitiveness in the market. In practice, the RFID application system has certain reference value and practical significance.

[ad_2]