Distribution Management of Digital Information Warehousing

[ad_1]

The FTRD2000 reader of our company has been successfully used in the digital warehouse of Kunming Tobacco Company. The project has passed the acceptance check and the system is currently running well.

The system uses pallets as the basic digital management unit for cargo management, that is, a UHF-915MHz electronic tag is embedded on the pallet. This will not affect the appearance quality of the goods, but also increase the overall digital average unit quantity of the goods, which facilitates the realization of accurate digital management of large quantities of goods. The entire system comprehensively applies digital warehouse management application software, computer wireless network technology, radio frequency readers, and electronic tags.

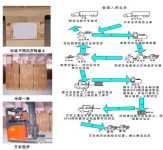

Incoming goods management

When the goods enter the warehouse through the entrance conveyor belt, the information of each pallet is written into the pallet through the entrance reader and writer, and then the delivery position is calculated through the computer warehouse management information system, and the inventory instruction is sent to the forklift vehicle system through the network system. It is required to be stored in the corresponding cargo space. At the same time, the database server generates corresponding back-end inbound data.

Shipment management

After receiving the shipping instruction, the forklift picks up the pallet goods at the designated cargo location. The reader reconfirms the accuracy of the pallet goods before fork picking, and then sends the pallet goods to the conveyor belt at the outgoing port. The conveyor belt reader at the outgoing port reads whether the pallet label information is accurate, and the shipment is verified without error.

Warehouse cargo management

Install electronic tags on the pallets of goods, and the management system in the warehouse can manage the goods through fixed installation of readers and handheld readers, which is convenient for inventory, search, and comparison. It is convenient to take inventory. The staff can clearly grasp the storage situation of the goods in the warehouse from the data collected and sorted by the system; to find the goods, if we use the traditional method to find a certain goods in a large number of stacked pallets, a lot of work will be required , And using the RFID system, the search process becomes so simple, the staff only need to hold the handheld reader to scan through the relevant area to easily and accurately find the goods that need to be searched.

Through the inventory management of the pallets of goods, the first-in first-out management in the flat warehouse is fully realized, which greatly improves the storage capacity of the warehouse. Through the above methods, in the digital warehouse management information system, functions such as: cigarette receipt management, cigarette pallet warehousing management, warehouse business management, cigarette pallet delivery management and other functions are realized.

Operational benefit analysis

1. Realize first-in first-out management of goods

2. Real-time management of warehouse inventory

3. Material tracking and graphical management

4. Optimize business processes and improve work efficiency

The successful application of this system has verified the good performance of the FTRD series readers, and at the same time has great demonstration significance for the use of UHF radio frequency technology in warehouse management.

[ad_2]