Shanghai millions of dangerous goods cylinders install RFID tags to ensure the safety of citizens

[ad_1]

As a very large city, Shanghai uses a large number of steel cylinders loaded with dangerous goods. In recent years, leakage and explosion accidents of steel cylinders carrying dangerous goods due to various reasons have directly affected the lives and safety of the people, and even caused some casualties. The reason is that most of the dangerous goods cylinders cannot be effectively managed and tracked. Some cylinders have passed the expiration date but are still in use; some cylinders are within the expiration date, but have not undergone annual audits and inspections for several years.Out of concern for the safety of people’s lives and property, the Shanghai Municipal Government is determined to pack millions of cans of dangerous goods in the city.RFIDLabels in order to effectively monitor and manage them.This work is included2006Shanghai Municipal Government10One of the “practical projects”.

Recently, Shanghai Keshitong Information Technology Co., Ltd.RFIDThe new army in the field, relying on its advanced technology and excellent independent intellectual property rights products, formally signed a contract to become the supplier of the project, providingRFIDData exchange management system.

project description:

Millions of dangerous goods cylinders this timeRFIDThe project system uses advancedRFIDIdentification technology, each cylinder has a unique serial number. The cylinder sending and receiving department sends the cylinder sent from outside to the inspection department for inspection. After passing the test, the electronic label is irreversibly pasted on the cylinder, and the cylinder label information is checked through a handheld reader. Perform identification and data writing, and then upload the data to the database management center through the computer serial port; for newly purchased steel cylinders, the inspection department directly pastes the electronic label, thereby uploading the data through the handheld reader.

In order to have a clearer understanding of the situation of each steel cylinder and facilitate more complete management, a second inspection is carried out before the cylinder is filled → scan and read → enter the database, which is the entire bottle link. After the cylinder is inflated (liquid), the filling information, including the filling medium, weight, and expiration date, is uploaded to the central database through the reader for management, which is the filling link. After the filling is completed, the logistics department will enter the warehouse. When shipping, the logistics staff will scan the label and write the customer, destination, and delivery time of the cylinder, and upload it to the database center for tracking and understanding of the cylinder at any time. Location, status, etc.

RFIDUsing verification mechanism and multiple encryption technology, it is impossible to forge and imitate, and at the same time, it is guaranteed that only the electronic tags issued by the system can be effectively identified; the information of each inspection, filling and related operators of the cylinder is detected by the handheld reader and written into the electronic tag In this way, each cylinder has its own unique “identity card”, avoiding duplication, chaotic management, or illegal imitation of cylinders.

The electronic tag is reusable, and the recorded data of the cylinder in and out can be read repeatedly through the above process, and the complete understanding of all circulation processes, greatly reducing the consumption cost of the traditional management process, and improving work efficiency.RFIDYou can quickly understand the process information of each cylinder, avoid the use of expired, leaking, and fake cylinders, and wear a “safety helmet” for each dangerous goods cylinder.

RFIDProfessional partners:

The core technical backbone of Keshitong has overseas work experience in internationally renowned high-tech companies. The coreRFIDProducts have independent intellectual property rights.Since the establishment of Keshitong, it has successively participated in2005Shanghai’s first batchRFIDDemonstration project, electronic label data collection and supply chain data service platform of Shanghai logistics modernization application project,2007Shanghai Special OlympicsRFIDProject integration and other projects have accumulated rich experience in the industry.Signed a million dangerous goods cylinders this timeRFIDThe project is not only a manifestation of the company’s strength, but also for the company’sRFIDThe development of the field provides a new platform.

ScienceToneRFIDThe server platform has excellent scalability, and can be well combined with the read-write equipment of various manufacturers, and does not need to be bound to a specific brand;RFIDThe server platform has a variety of different database interfaces, which can be easily combined with enterprise back-end software. If there is a new business process, it can also be directly added to the original process; the platform also provides data center functions to facilitate enterprises to easily process large quantities of data.

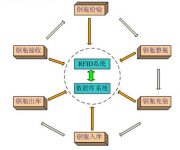

KTISystem network structure diagram

KTIThe main components of the system

RFIDapplication server

RFIDControl server

PCworkstation

Handheld reader

Pocket PC

RFIDLabel

KTIMain modules of the system

System Management

Label management

Information collection management

Item tracking management

Query management

Project implementation effect

11) Improve product traceability and reduce product recall costs;

21) Anti-counterfeiting of steel cylinders can be achieved well, and counterfeit products can be prevented from causing huge losses to enterprises and the people;

3) Query all kinds of information of dangerous goods steel cylinders immediately, which improves the production management level and work efficiency of steel cylinder filling plants;

4) Improve the comprehensive tracking and monitoring level of dangerous goods steel cylinders, realize the alarm of the regular inspection time of steel cylinders, and ensure the people’s livelihood.

The safety of life and property.

Summarize:

This time, it passed over one million steel cylinders loaded with various dangerous goods in Shanghai.

RFID

Effective monitoring and management can clearly and correctly understand the location, status, and annual inspections of these steel cylinders, thereby effectively strengthening the safety protection of the people’s lives and property; at the same time, realizing the anti-counterfeiting of steel cylinders and avoiding counterfeit products to enterprises and people The potential huge losses caused by the masses improve the production and logistics management level and work efficiency of related enterprises; improve the traceability of steel cylinders and reduce the cost of steel cylinder recalls, which directly increase the economic and social benefits of enterprises.And further expanded

RFID

The scope of application is

RFID

The vast development of the city opened up another Roman road.

[ad_2]