Analysis of adhesive die-cutting overflow and solutions (part 1)

[ad_1]

Die cutting is an indispensable link in the processing of stickers, and it is also an important link that is most easily overlooked by the technical department of the processing company.

The quality of the die-cutting effect directly affects the customer’s experience. Die-cutting glue overflow is the most likely problem, and it is also an old and difficult problem that plagues the majority of label processing companies. Today we will analyze this problem and share it with you. Some common solutions.

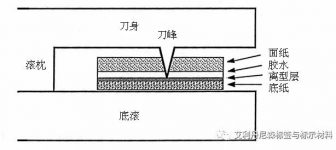

The self-adhesive structure is a sandwich structure: surface material / glue / bottom paper (with silicone oil).

Self-adhesive die-cutting belongs to precision die-cutting, which requires cutting off the surface material and glue without hurting the bottom paper, and the waste is discharged before the glue on the knife-edge section is reflowed and combined. Due to the influence of many factors in the actual processing, it is difficult to achieve this ideal situation.

There are two manifestations of glue overflow during die-cutting and glue overflow after die-cutting. Today we will talk to you about the overflow of glue in the die-cutting process. The edge overflow during the die-cutting waste discharge process and the sharpness of the die cutter, the adjustment of the die-cutting pressure, the selection of the die-cutting pad material, the softness of the adhesive material glue, and the paper path before the waste after die-cutting Settings and other related.

01.

Excessive die cutting pressure

As shown in the figure below, the die-cutting knife marks are too deep. The downward process of the die-cutting knife will over-squeeze the material. After the waste is discharged, the edge of the label will overflow. It is recommended to use the dyeing method to quickly detect the depth of the backing paper knife marks to avoid excessive pressure. glue.

02.

Die cutting pressure is too small or the knife is not sharp enough

The part of the film is not cut, and the rubber film is torn when the waste is discharged, and the glue line is generated, which causes the edge of the label to overflow; (in serious cases, the waste tape will appear) For this kind of problem, it is recommended:

-Properly increase the die cutting pressure to ensure that the film is cut off

-Use a cutting knife with a smaller and sharper corner for die cutting, or use a knife with Teflon anti-stick coating for die cutting

-Adopt the oblique waste and discharge method, or the peeling plate waste and discharge method to alleviate the situation of the knife edge drawing of the glue wire/label

Oblique waste discharge method

Peeling board waste disposal method

Choice of the angle and hardness of the mirror blade

03.

Choice of die-cut bottom plate

The bottom plate is the benchmark for adjusting the die-cutting pressure. The flatness, thickness uniformity, and hardness of the bottom plate directly affect the die-cutting effect. The die-cutting bottom plate shown in the figure below is too soft, which will cause the die-cutting to lose pressure. During die-cutting, the glue at the position of the knife mark is excessively squeezed, causing the glue to accumulate on both sides of the knife edge, causing glue overflow.

Solution: It is recommended to use a polyester sheet with uniform thickness and appropriate hardness (such as Lumuller) as the die-cutting bottom plate, and it is not recommended to adjust the die-cutting pressure by sticking a tape on the surface of the bottom plate.

04.

MD direction unilateral overflow

After die-cutting, the paper path is too long before the waste is discharged. After multiple times of squeezing of the meshing wheels, the glue will flow back, and the glue at the knife mark will recombine, and the glue will be drawn when the waste is discharged. (Usually it is a unilateral overflow in the MD direction).

Solution: Shorten the paper path before the waste is discharged after die cutting, and reduce the squeeze of the die-cutting knife edge glue by the meshing press wheel. If it cannot be adjusted, the method of solvent penetrating and dissolving the knife seam glue can be used to avoid the waste of drawing glue before the waste is discharged.

Knife slit solvent permeation method before waste discharge

[ad_2]