Solutions for applying active tags to manage production molds

[ad_1]

1. Project purpose

Help to realize the management of mold in and out records

Help locate, locate and place the mold in the warehouse

Help to record the usage of the mold and understand the specific information such as the working status, life cycle and maintenance status of the mold

Help to monitor the position of the mold, facilitate the inventory of the mold, and prevent the mold from being lost or stolen.

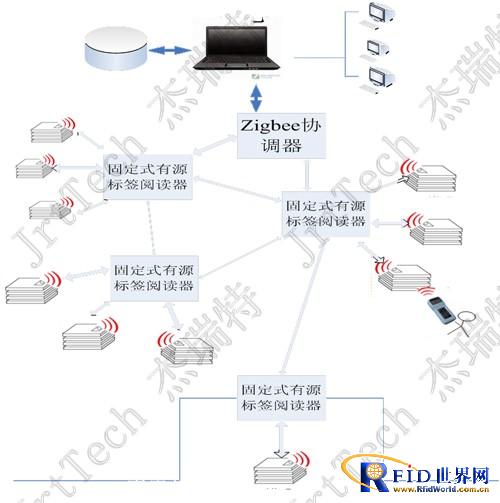

Second, the block diagram of the program composition

3. Introduction of main components

Active tag: The active tag is embedded with the Zigbee communication protocol as the end node in the Zigbee link.Install on the mold when in use, and build in the system before useActive tagCorrespondence between ID code and mold information, the system can find the corresponding mold information (such as material number, serial number, molding times, last use time, etc.) through its ID code. At the same time, the ID code is used to locate the mold. This label reads successfully with indicator light.

Fixed active tag reader: The reader is embedded with Zigbee communication protocol, as the network node in the Zigbee link. Each reader has a unique number, which can correspond to the area where it is located; when it is used, it is installed near the mold that needs to be managed, and all active tags in its area can be read, and then the corresponding mold can be found. Multiple readers can form a wireless communication network, and the system can easily read the corresponding active tags through this network to find the corresponding mold. This reader is equipped with sound and light instructions for successful reading, and a position display screen at the same time.

Portable active tag reader: The reader is embedded with Zigbee communication protocol, and it can communicate with the active tag in the reading area point-to-point, so as to accurately find the corresponding mold. This reader successfully reads with acousto-optic instructions and color screen to display mold information.

4. Description of the work process of the program

1. Mold storage and placement process

a. The library door reader reads the active tag on the mold, and wirelessly sends the tag ID and other information to the center

b. After the center finds the corresponding mold information, it sends the mold storage location information wirelessly to the fixed active tag reader in the corresponding position in the warehouse.

c. ReaderAfter receiving the information, a light-emitting alarm will be issued, and the mold placement personnel will place the mold in the area according to the instructions

d. After placing, the reader will read the label on the mold again to reconfirm whether it is placed correctly.

2. Mold delivery process

a. The center finds the corresponding mold location information and the ID code of the active tag on the mold according to the mold use sheet, and sends it wirelessly to the reader at the corresponding location

b. The reader reads the ID code of the active tag on the mold in the area for comparison, and when it finds a matching ID, it will give an audible and visual prompt

c. The mold picker carries the active tag handheld reader to the prompt area, and sends the active tag ID that needs to pick up the mold. After the corresponding tag is received, the indicator light on it will light up, and the mold that needs to be out of the library is determined according to the indicator light;

d. At the door of the warehouse, the reader will read the tag ID on the mold for confirmation.

3. Mold inventory process

a. Enter the mold information that needs to be searched, and send the corresponding active tag ID to all readers wirelessly

b. Each reader sends the ID to the active tags in their respective areas for comparison, the active tag indicator of the successful comparison will be displayed, and the information will be returned to the reader at the same time

c. The reader sends the successful search information and its own identification code back to the system, and the system determines the position of the mold based on the information.

e. When the mold position moves, the position of the mold can be re-determined through the above process

d. If there is no search success information returned, the system will prompt that the mold cannot search for information.

[ad_2]