Textile sample detection system based on RFID technology

[ad_1]

1. Project Background

my country is a major exporter of textiles, and China’s textile exports account for about 70% of the world’s total textile exports. With the development of the textile industry and the emergence of new formats, the technical barriers to trade in the United States and the European Union have led to the continuous increase in the testing demand for exported textiles. Therefore, the scale of third-party commercial testing laboratories has continued to expand, which has a great impact on the laboratory’s Management has put forward higher requirements.

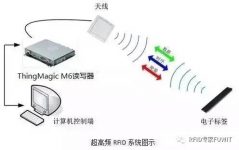

The textile sample detection system based on RFID technology can effectively improve the efficiency of textile sample detection. Shenzhen Quan Shunhong Technology Co., Ltd., as ThingMagic’s agent in China, a professional RFID equipment and technical service provider, provides you with ThingMagic’s high-quality RFID equipment and professional technical support.

The traditional textile sample management system usually uses barcode labels or manual sample management documents, etc., and these sample library operation modes and data collection methods have been difficult to meet the fast and accurate requirements of sample library management, and there are obvious shortcomings. Not only is it prone to errors , and the work efficiency is low, and each node of the operation process is uncontrollable, which is not conducive to real-time tracking of the sample detection status.

The use of new information technology means, with the design of reasonable workflow and sample flow, improves the work efficiency of the laboratory, facilitates the management of sample flow in the laboratory and the real-time tracking of textile samples, which is of great significance for improving the comprehensive competitiveness of the laboratory. .

2. Introduction to RFID Technology

RFID radio frequency identification technology is an emerging high-tech technology that has caused changes in the field of automatic identification after bar code. Technology for automatic identification of item information.

Compared with traditional identification technologies such as optical identification and barcode identification, RFID technology has the following advantages:

1) RFID does not require manual intervention and no contact operation;

2) RFID can work in various harsh working environments;

3) RFID reading and writing equipment can identify high-speed moving objects, and can identify multiple objects at the same time;

4) RFID can be identified through certain obstacles and has good penetration;

5) RFID tags can store data and repeatedly erase and write, and RFID tags can be recycled;

6) RFID reading and writing equipment has high recognition accuracy;

7) RFID tag information is safe and difficult to copy;

8) RFID tags are small in size, can be customized and packaged, and have wide adaptability.

The textile sample detection system based on RFID technology makes full use of the characteristics and advantages of RFID technology. When entering and leaving each detection department, the RFID equipment can read all the RFID tags in the sample basket in batches, which greatly improves the collection efficiency. Recycling greatly reduces the loss of disposable electronic labels and saves the cost of consumables. The data of each RFID collection channel is automatically uploaded, which can provide accurate and real-time data flow for background management, and provide great convenience for real-time inquiry of the current inspection progress, location and other information of cloth samples, thereby improving the management level of textile samples in the testing laboratory. and comprehensive competitiveness.

3. Business process analysis

General Commercial Textile Sample Testing System Based on RFID Technology Textile sample testing in laboratories includes the following processes

1) Sample collection

The customer submits the sample and test application form. The test application form should generally include customer information, sample information, and test item information;

2) Create a task list

After the laboratory receives the samples, the relevant customer service personnel will check the application form information and the conformity of the samples, and create a work task list in the textile sample detection system based on RFID technology;

3) The laboratory receives tasks

After the laboratory of the textile sample testing system based on RFID technology receives the work person list, the test will be divided into relevant test groups according to the test items of the task list; general commercial textile laboratories will be divided into several test groups according to the characteristics of the textile test items. Groups, such as color fastness group, shrinkage group, physical property group, composition analysis group, combustion group, chemical test group and so on. Such grouping is also to improve detection efficiency, and the same test can be arranged at the same time;

4) Do the test

After each test team receives the samples, according to the characteristics of the test items on the work order, the test is carried out according to the process. In order to improve the detection efficiency of the textile sample detection system based on RFID technology, some standard detection processes can be carried out in an assembly line.

5) Result entry

When the test is completed, the laboratory inspector of the textile sample testing system based on RFID technology will write the results on the work task list or data sheet, and then the relevant personnel will enter the test results into the textile sample testing system based on RFID technology;

6) Issue the report

After the results are entered, the test results will be reviewed by senior personnel. After the review, the relevant personnel will typeset the customer information, sample information, test results and result judgments that have been entered into the RFID technology-based textile sample testing system, and generate a final report. issued.

According to the above process description of the third-party textile laboratory, it can be seen that the work order runs through the entire detection process. Therefore, the textile sample detection system based on RFID technology is to manage the work order. Through the management of the work order, the textile samples under the work order can be managed.

4. Hardware selection

According to the relationship between the work order and the textile samples, the textile sample detection system based on RFID technology can realize the real-time tracking and management of the inflow and outflow of textiles on the sample board at each node through the binding of the RFID electronic tag and the textile sample plate one by one.

4.1 Flowchart

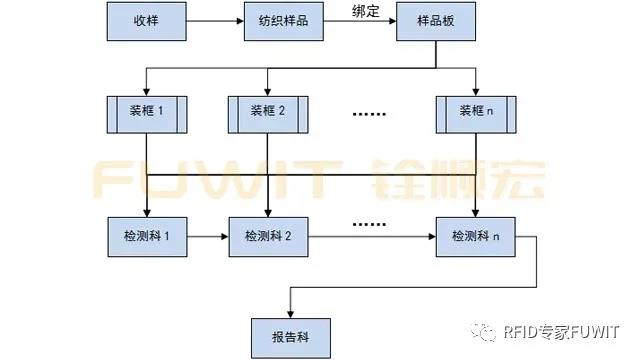

Taking the work task list as the management goal and the sample board management carrier, the overall flow chart of the textile sample detection system based on RFID technology is as follows:

After the textile sample is collected, a task order number is generated according to the task order, and the staff binds the sample to the sample plate. At the same time, the RFID tag of the sample plate is bound to the task order number and framed. The framed sample plates will enter each testing department for testing, and finally generate test results and reports.

4.2 Topology and Function

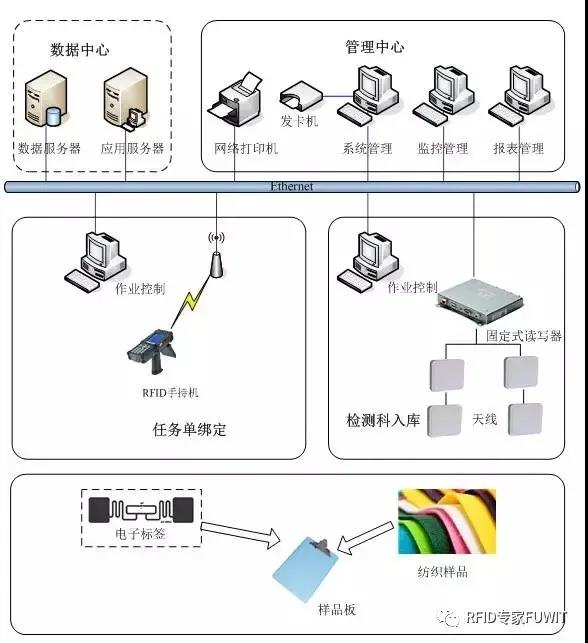

The circulation of the textile sample detection system based on RFID technology in the laboratory is mainly composed of two parts: the task list binding system and the inspection department storage system. The topology diagram of the textile sample detection system based on RFID technology is as follows:

4.3 Operation process

4.3.1 Task list binding

The binding of the task sheet is mainly to bind the textile sample to the sample plate. Each sample board will be prefabricated with an RFID electronic label, and according to the asset coding rules of the enterprise, the sample board will be pre-written with the data of the RFID tag.

After the RFID electronic tag is bound to the sample plate, it can be used in the textile sample detection system based on RFID technology. The RFID sample board first came to the test stand where textile samples were made. Textile samples all have a task list, and the task list contains a barcode associated with it. Scan the barcode and the RFID sample plate label through the RFID handheld, and transmit the related information of the two to the system background to complete the electronic label binding system process.

4.3.2 Warehousing of testing department

After the sample plate with textile samples is made, it is put into the circulating plastic basket and is arranged to be transported to each testing department. The RFID reading effect is installed in each laboratory, and the warehousing process can be used to greatly shorten the warehousing time. , reduce the intensity of manual work, automatically record the warehousing status, and realize the visualization and traceability of the circulation process of textile samples in various laboratories.

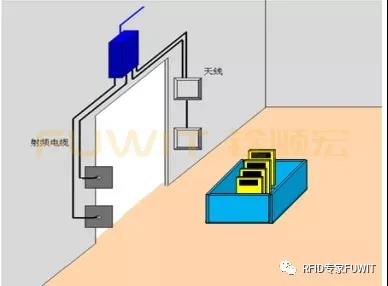

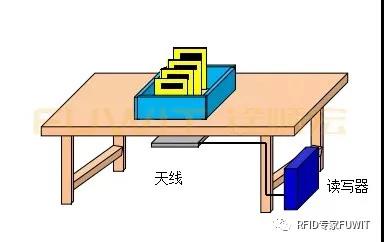

According to the more optimized selection of the installation conditions and reading performance of the inspection department, the RFID collection points of each department mainly include channel-type collection points and desktop collection points.

In the end, whether it is through the channel collection point or the desktop collection point, the textile sample board information entering each testing department of the textile sample testing system based on RFID technology will be read in batches and uploaded to the background system to complete the storage of samples. process.

4.4 Application Results

The textile sample testing management system based on RFID technology can meet the expectations of clothing testing institutions for textile sample management and achieve the project goals. The main performances are as follows:

1) Using RFID technology, a large number of RFID tags can be read at one time, thus eliminating the tedious workload of manual entry, greatly saving labor costs and improving work efficiency;

2) The change information (type, location, name, quantity, etc.) of the sample can be recorded in time through the location RFID tag and the sample RFID tag, which reduces the human error when entering the sample and improves the operation efficiency of entering, exiting, moving, and disk storage. accuracy;

3) Due to the improved reliability of the warehousing and other operations of the textile sample detection system based on RFID technology, many unreasonable orders are avoided, and the operation cycle of supply and distribution is greatly improved;

4) The use of RFID radio frequency technology can greatly improve the efficiency and accuracy of the picking and distribution process, and speed up the speed of distribution;

5) Visual tracking of sample status can provide scientific basis for testing institutions to formulate reasonable testing plans.

Five, equipment hardware selection

The textile sample testing laboratory conducts data collection and daily business management through RFID technology, and establishes a textile sample testing RFID management platform, which realizes the efficiency of textile samples entering and leaving the testing department, reduces the travel rate, optimizes business processes, and reduces the labor intensity of operators. The goal of reducing overall laboratory operating costs. In this system, the speed and accuracy of RFID data collection are very important, and the key hardware is the fixed RFID collection equipment deployed in the detection department.

The fixed RFID acquisition equipment is mainly deployed at the entrance and exit of each testing department or in a specific area, and it is necessary to quickly quantify the label information of the incoming and outgoing sample plates in batches.

exact collection.

5.1 Fixed reader

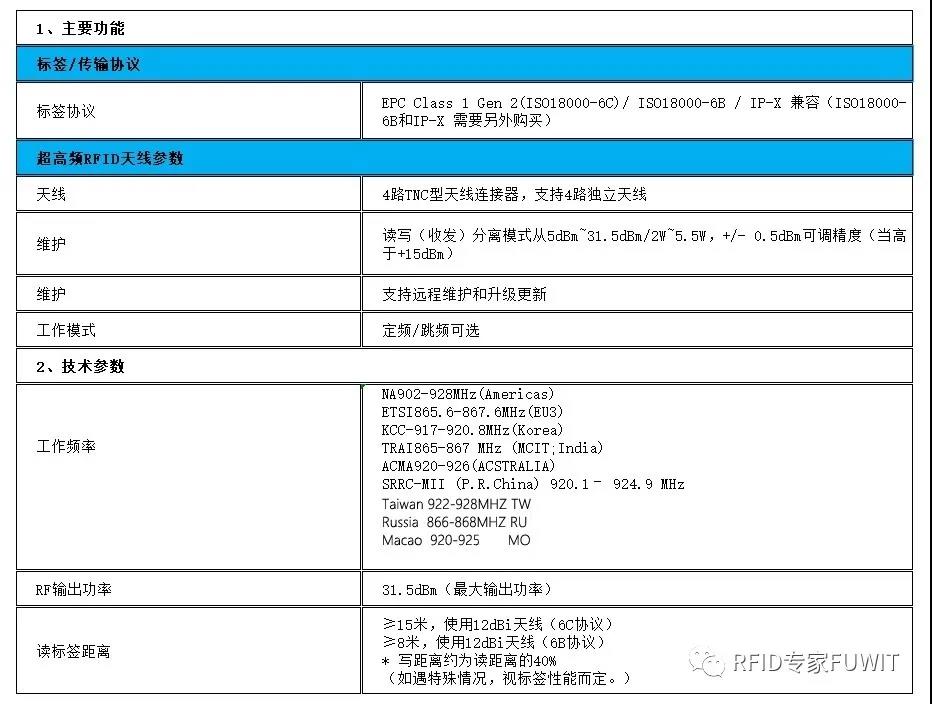

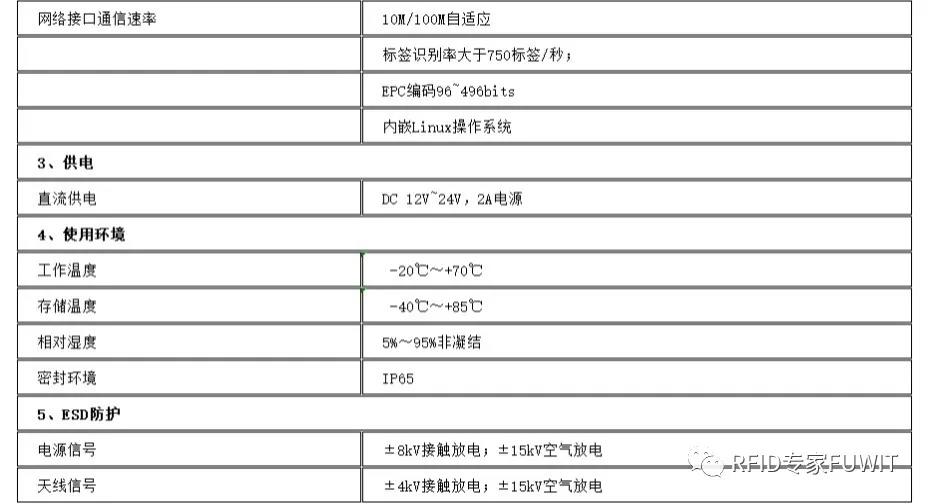

FU-M6-A is integrated with ThingMagic M6 module; it has a reading speed of 750 labels per second, a powerful multi-label anti-collision algorithm, and high-speed information reading and processing capabilities, which can maximize the accuracy on the premise of ensuring accuracy. increase the number of garments in and out of the warehouse.

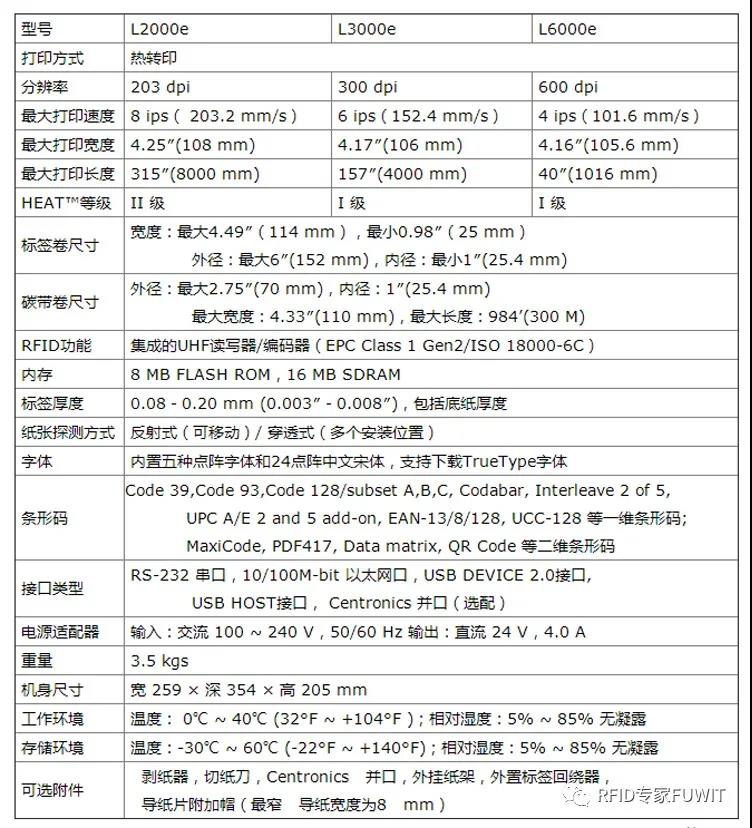

5.2 RFID Printer

The UHF RFID barcode printer has more efficient card issuance efficiency and easier operation, which can help customers to realize the initialization process of large batches of labels in a short period of time. At the same time, other visual information such as barcode can be printed on the surface of the label, so that the label has RFID function and good compatibility with the barcode system.

Features

1) HEAT™ (Heating Equilibrium Adaptive Tuning) intelligent heat balance control technology is for fine control of the entire printing process;

2) The comprehensive heating efficiency of the UHF RFID printer is increased to more than 30%, which reduces energy consumption and is environmentally friendly.

3) Precise positioning, can read and write labels with 12 mm inlay spacing (inlay spacing), currently on the market supports the smallest inlay spacing label reading and writing printers. The antenna design of the verification label is printed first and then read and written, and the detection rate of bad labels is 100% to ensure the accuracy of business management.

4) One-click label antenna positioning and first label printing function, simple operation, high efficiency and convenience, and lower cost of use. The key transmission parts are designed with metal bearings, and the precision is meticulous and perfect, which protects the inside of your printer from long-term friction and deformation, and achieves a stable and durable product.

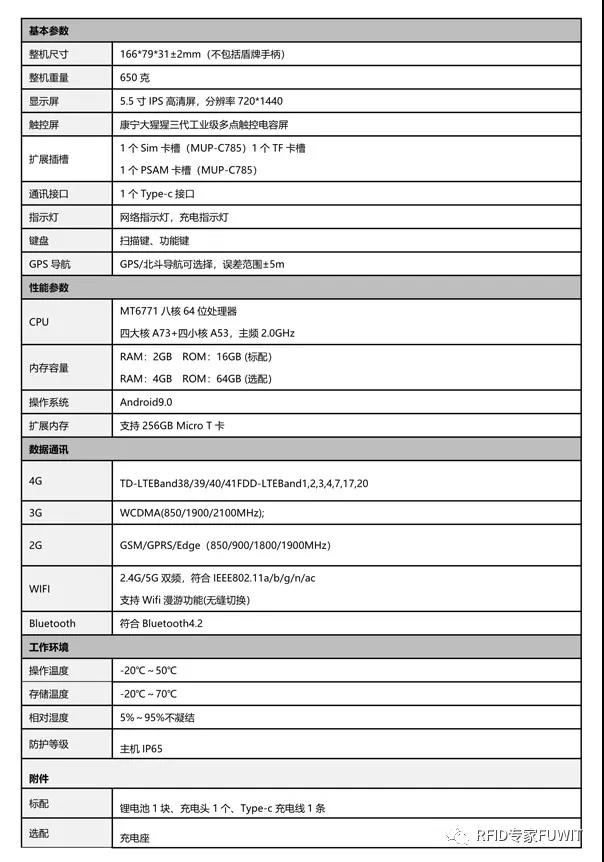

5.3 RFID handset

Quan Shunhong W6100 RFID smart handheld is a portable smart data acquisition device developed based on Android system, integrating 1D or 2D barcode scanning, 4G full Netcom, GPRS, WIFI, BLUETOOTH, RFID functions; friendly interface, easy to operate, Integrating ThingMagic high-performance modules, it has the advantages of efficient inventory, remote scanning, and accurate reading; it is suitable for multi-scenario applications such as warehousing and logistics, jewelry stores, and archive books.

Features

1) Simple body design, high-definition large-screen display The simple body design is used, and it is displayed on a Corning Gorilla 5.5-inch IPS high-definition display. The item resolution of 1440*720 and the arc design of the corners take into account the comfortable grip and the drop resistance of the machine itself.

2) Powerful fast charging and WiFi roaming function Equipped with optional 9000mAh polymer lithium battery, long battery life, and supports fast charging function, the single charging time is shorter. And powerful WiFi roaming function, which can realize seamless switching of WiFi hotspots and maintain an uninterrupted network connection experience.

3) Excellent RFID reading and writing function, multi-tag long-distance reading and writing, using omnidirectional helical antenna with professional scanning handle and shield, supports ultra-high frequency single-tag and multi-tag reading, longer distance, faster efficiency, complete The machine performance is more stable and the effective reading distance can be up to 20m.

[ad_2]