RFID file management system-RFID smart file management-dongzhi technology

[ad_1]

1. Project background

1.1 Object Orientation

DONWIT RFID smart file management system is an informatized, intelligent and standardized system that relies on mutual cloud computing, big data, RFID technology, database technology, AI, and video analysis technology for unified management and analysis of archives.

In recent years, my country’s archives business has made considerable progress. With the expansion of the scale of the archives business, the number of archives is increasing day by day, the types are becoming more diversified, and the amount of information is expanding rapidly. The informatization of archive management urgently needs a more advanced and complete automated management system solution. In this context, a file management system based on radio frequency identification technology (RFID for short) came into being.

The RFID file management system is based on advanced RFID technology, combined with database technology, object-oriented development technology, signal processing, weak signal detection and other technologies to build a physical file information management system, which realizes the digital management of physical files and the management of circulation links. , File warehouse management, improve the accurate monitoring and management of the archives’ entire business process.

1.2 Archives needs and construction goals

The RFID file management system of Dongshi Technology is based on advanced RFID technology, combined with database technology, object-oriented development technology, signal processing, weak signal detection and other technologies to build a physical file information management system, which realizes the digital management and management of physical files. Circulation link management and archive warehouse management have improved the precise monitoring and management of the archives’ entire business process.

This system adopts B/S architecture, logs in through a browser, counts through warehouses, and relies on the system to realize the information management of file entity inventory and shelving. It can not only master the accurate number of files, but also master the file category and real-time location information, thereby improving the efficiency of file warehouse management.

By scanning the archives’ dense shelves and the archives with RFID tags, the archives can be collected for shelf location information and archive address information, helping to arrange, find and count specific archives. After the shelf position information of the archive rack is merged with the shelf position distribution map of the archives warehouse, a detailed data model diagram of the archive rack distribution address can be established, which provides a quick man-machine interface for daily archive management.

Increase the processing speed of archives business through online lending and return services. An automatic inquiry service (inquiry machine) is set up in the borrowing hall, and the warehouse manager is equipped with a mobile handset to improve the efficiency of searching for files.

The application of the file management system is a comprehensive application of multiple RFID technologies. The application of the intelligent file rack provides convenience for the file management personnel, and also provides a more efficient way to improve the efficiency of file management and reduce the cost of file management.

The intelligent warehouse management system now carries out a comprehensive and intelligent management process for the warehouse. The system can realize seamless connection with the original collection file system, and carry out simulation and comprehensive management functions for the warehouse. RFID technology is used for the archive entity to intelligently manage the archive entity.

2. The overall idea of the system

2.1 System application architecture

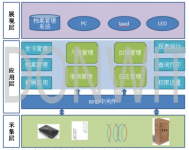

The application architecture of Dongshi Technology’s system is divided into three logical levels: acquisition layer, application layer, and presentation layer.

· Acquisition layer: Readers (RFID channels, integrated readers, handhelds, etc.) read the electronic tag data, and then transmit it to the server through the network or other means.

· Application layer: realize RFID file management application functions at the application layer, including tag management, admission management, exit management, inspection management, inventory management, statistical analysis, extended applications, etc.

· Presentation layer: Users can log in to the system through PC terminals, handhelds, display screens, etc.

2.2 Electronic label scheme

This program mainly recommends the use of RFID file tags produced by Daoyuan. The label is used with good sensitivity and is widely used in books, archives, logistics and other industries.

2.2.1 Label information setting

The information items stored on the file label include: file type, file name, file number, file security level, storage time, preservation period, summary of file content, etc.

The information items stored on the storage location label include: storage location type, storage location number, stored file number interval and quantity.

2.2.2 Making the label

It is recommended to use Label for label production, which can print information on it and paste it in the position required by the customer.

2.2.3 Label installation

In the file label, the electronic label is sealed into a card or self-adhesive paper and affixed to each file box or file. The file box is made of plastic or paper material, which facilitates the pasting and removal of RFID tags. At the same time, the box body is not easy to be damaged and can be recycled to reduce storage costs. Taking into account the need for moisture and moisture resistance, a small amount of desiccant can be placed in the box.

3. Project design principles

The construction of the RFID smart file management system of Dongshi Technology, on the basis of conforming to the definition of development requirements, also leaves sufficient space for the further development and expansion of the system. In the design, other developments such as food safety traceability should be considered, and unified planning and design should be carried out. Since the construction of this project is based on business and data, the design principles are as follows:

· The principle of meeting business/management needs

Starting from actual needs, following the principle of business/management application as the leading priority, based on the business data most needed by customers, the goal is to achieve food safety traceability requirements.

· Unified planning, standards and specifications

System construction should adopt the strategy of “unified planning, step-by-step implementation, unified standards, and risk reduction”. Under the premise of following the management norms, the overall planning shall be carried out in advance to establish the food safety traceability system design and standard system construction, and the construction shall be carried out step by step. The design of the overall planning scheme should proceed from a simple and practical point of view, follow the principle of integration, and reduce system complexity.

· Mature and advanced

On the premise of ensuring maturity, practicability, and reliability, system construction must adhere to the principle of advancement in both design ideas and implementation technologies.

· Safe and reliable principle

System construction must have high security and high reliability. Strict and complete security measures should be adopted to ensure the reliability and confidentiality of business systems from the aspects of networks, systems, applications, users, and data. Service quality and information security are fundamental to IT planning, design, and construction. It is necessary to consider the establishment of unified and complete safety standards, safety technical measures, and safety management systems, formulate clear data classification protection levels, and establish unified user management and access control mechanisms.

· Easy maintenance and expansion principle

The system should be easy to install, easy to configure, easy to use, etc. The overall structure of the system is flexible, and simple maintenance tools should be provided to meet the requirements of function expansion; at the same time, it should be able to integrate with other information systems and work together.

The above points are interrelated and complementary to each other, and constitute the overall guiding principle of the construction of this project.

4. Business function introduction

Dongshi Technology RFID smart file management system mainly has the following functions:

Label initialization

Before the label is put into the warehouse, a special person will issue a card to label the goods. The information on the label includes information such as the type, model, and date of manufacture of the file.

Electronic label initialization mainly completes the binding of file information and electronic labels, writes electronic label codes (EPC), prints electronic label information, binds labels and files, and verifies electronic labels and other basic tasks before circulation. The system provides convenient modification functions, which can modify electronic label information and record the modification in the system. It also provides label modification functions.

Warehouse management

It is necessary to realize seamless connection and realize the automatic recording of files in and out of the warehouse, including the automatic registration of the file’s in and out time and the person who handles it, so as to facilitate the timely understanding of the file in and out of the warehouse.

File on the shelf

The archive storage is a function of simulating the physical storage of the archives. It is required to automatically generate the storage address of the archives through the operation of the archives storage, so as to realize the automatic association of the archive entities and the archive data. Files can be automatically put on the shelves in batches, including which warehouse, which shelf or floor the files are stored in, and the storage location index of the files is automatically generated after being put on the shelves.

File transfer

The files stored in the warehouse need to be adjusted regularly according to the receiving and appraisal situation. The file adjustment includes the adjustment of the warehouse room, the adjustment between the dense racks, the adjustment between the rows, the adjustment within the same row, and the adjustment within the same row.

(1) Warehouse room adjustment: It is necessary to have the function of adjusting files from warehouse A to warehouse B. After adjustment, the storage location index is updated under the dense shelf of the new warehouse, so as to realize the adjustment of archives.

(2) Inter-shelves adjustment: It is necessary to adjust the A-shelves to the B-shelves. After the adjustment, the storage position index is updated to the new dense racks, so as to realize the file-shelves adjustment.

(3) Adjustment between rows: It is necessary to adjust from row A to row B within the same compact rack. After adjustment, the storage location index is updated to the bottom of the new row, so as to realize the adjustment between rows of files.

(4) Adjustment within the same row: It is necessary to have the adjustment from row A to row B within the same row. After adjustment, the storage location index is updated to the bottom of the new shelf, so as to realize the adjustment of files in the same row.

(5) Adjustment in the same row: It is necessary to have the function of adjusting the order of the files in the same row.

Archive retrieval location

To provide the archive retrieval function, you can query the archives according to the query keywords. After you find the data you want to find, you can locate and track the archives, and click to view the archive catalog and the original file.

Warehouse Statistics

Warehouse statistics is to provide real-time warehouse statistics function, which can automatically count the following information:

(1) It can automatically count the total number of files stored in each warehouse, the number of files that can be stored, the vacancy rate of the warehouse, etc., and it can also automatically count the details of the files stored in each warehouse, such as file type, fond, storage period, confidentiality level, etc. , At the same time, the vacant situation of each dense shelf can be automatically statistically summarized;

(2) It can automatically count the total number of files stored in each dense rack, the number of files that can be stored, the vacancy rate of the dense rack, etc., and it can also automatically count the details of the files stored in each dense rack, such as file type, fond, storage period , Security level, etc., and at the same time, the vacancy situation of each column and each row in the dense rack can be automatically counted and summarized.

(3) The system also provides a custom statistical function, which can customize various conditions for grouping statistics according to needs, and output the statistical results.

File review and return

The system automatically seamlessly connects with the original collection archives comprehensive system, and automatically records and displays the retrieved files. The compact rack is intelligent, and it can also be connected with it, which will automatically store the compacted files. When the shelf is opened, the warehouse manager can directly enter the extraction file. Automatic reminder when repeating reading. After the retrieved files are returned, the compact shelf will also be automatically opened, and the warehouse manager can put the files directly in, and the system will automatically restore the loan sign so that it can be retrieved again next time.

The system must also support the barcode recognition function. The barcode can be recognized by the scanning gun, and then the dense racks that need to be returned are automatically located, so as to realize the return operation function.

The system will also automatically record the retrieval and return of each file, so as to respond in a timely and dynamic manner to the retrieval status information of the physical files of the warehouse, and can perform statistics on it.

File inventory

Warehouse staff only need to scan through RFID handheld devices when performing inventory operations. The system automatically counts the number of scans, and compares the differences with theoretical data obtained from the daily operation records in the system, and can view the difference location information.

File anti-theft

Set up the file archive area detection channel at the location where it is needed to detect the legitimacy of the file file passing, and prevent the file file from being carried out of the archives or into illegal areas intentionally or unintentionally.

File track display

Through real-time tracking of the position of the electronic tag, the movement track of the electronic tag is automatically generated and displayed in a graphical form.

[ad_2]