Industrial RFID solution to solve the chaotic management of tank yard

[ad_1]

1. Project background

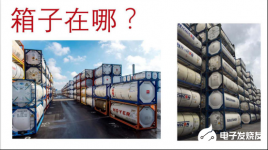

The chaotic management of tank yards has a long history. How to quickly pick up containers not only affects the internal operation management problems of the yard, but also plagues the entire supply chain because of the arrival time of a box, the loading company, the tank owner, and the fleet. The problem of collaboration efficiency!

The key problem here is that the one or two forklift personnel who are most familiar with the location of the boxes are the one or two forklift personnel (no matter how many people are not economical but easy to make mistakes), the forklift personnel are responsible for the on-site process of entering and exiting plus the daily box circulation. Know the location of the box best.

However, when manpower is poor, small storage yards can still know the location of the cans well. However, some large storage yards with more than 4 layers of boxes and large trucks will increase the number of people. The cost of turning over the box is high, the efficiency of carrying the box is slow, and there are problems such as working hard day and night. Sometimes I have to wait for the rain to stop, wait for dawn, and wait for someone to help me to find a box. I have spent a lot of manpower and material resources, but I still don’t know where it is! As a result, a series of plans for storage yards, fleets, factories, and shipping schedules are disrupted. .

2. RFID application scheme

1. RFID binding

When the truck transports the cans to the container yard, the guard binds the RFID card (ID data) with the can information (box number, order, company, contents, etc.) provided by the truck driver in the system, and the binding is completed and stored in Temporary storage point.

2. Identify the tank

The forklift approaches the tank to read the RFID data, and the system retrieves various information of the tank according to the ID.

3. Tank storage

According to the information of the tank, the staff of the tank yard will store the tank in the designated place. In the process, the latitude and longitude information, altitude information, storage time, etc. are continuously obtained, and the information is stored on the server.

4. Query of tank information

During the movement of the tank, the current box number information and transportation track will be displayed on the tablet in real time until the storage of the tank is completed and the RFID is separated.

3. Advantages of RFID system

Tank yard management is an extremely important link in the tank transportation system, and it is also a very important task. Its contents include the preparation, leasing, transportation, storage, handover, distribution, inspection and repair of tank containers.

At present, tank management is mainly realized through information management system combined with manual non-real-time manual data entry. Some advanced management systems adopt image recognition technology and use cameras to identify the box number. These traditional scheduling methods always have problems such as low efficiency, high labor cost, high error rate, and poor real-time performance.

The RFID tank yard management system is far more efficient than traditional methods. Electronic tag (RFID) technology was tentatively applied to tank management, and achieved good results. It is of great significance to effectively solve the storage and turnover of tanks and to improve the economic benefits of enterprises.

[ad_2]