Analysis and Solution of Picking and Packing System Based on RFID Clothing Industry

[ad_1]

Chapter 1 Demand Analysis

With the rapid growth of corporate brands, and in the face of rapidly changing demands in the market, the original factory packaging and logistics links obviously cannot keep up with the pace of corporate development.

According to statistics, the number of complaints about delivery errors is high, of which up to 40% of the original box complaints.

1.1.2 The problem of too long supply cycle

Changes in the internal and external environment and the problem of excessively long supply cycles have become increasingly prominent.

The current supply cycle has been hovering between 60 days and 90 days. However, similar foreign companies have implemented the QR strategy and have realized the replenishment period has been reduced to less than 2 weeks. Spain ZAYA can deliver to the store in the shortest time of 3 days.

1.2 Demand analysis

Basic description of requirements: It is difficult to guarantee the accuracy of packing with existing packaging technology, and the shortage of original boxes is more prominent, which cannot adapt to the new business model of PPT projects. It is planned to use the fourth floor of the Foshan factory as the test base for the PPT project. The processes including cutting, sewing, finishing, packaging, etc. are planned and designed in accordance with the requirements of the PPT project, and the application of RFID technology is proposed to help realize the production for 7 days. , Logistics goal of 7 days. Taking into account the cost and schedule factors, this period does not plan to adopt an automated packaging production line. Put forward the requirements for the interface with the existing production management system. It is planned to start construction of the pilot plant in November 2007.

1.2.1 System goals

Use RFID technology to solve the current shortage of original boxes and low efficiency in the link from product offline to delivery before delivery, and realize accurate and fast sorting and packing of clothing products to meet the goal of shortening the supply cycle to 14 days. .

1.2.2 Precise packing

In view of the poor packing effect in the past, enterprises attach great importance to the packing effect. According to our understanding, the following points can be summarized:

1. The quantity must be accurate;

2. Easy to operate;

3. High degree of automation is not required;

4. It is easy to promote and use in most existing factories;

5. The lowest cost;

Analysis: Comparing the various existing packing schemes, if you want to meet the above packing requirements, the best one is the picking and packing system scheme using RFID tag technology. In addition to RFID tags, barcodes are the most used identification technology. The advantage of bar code technology is that the price is relatively cheap, but it does not have the ability to be remotely identified and multiple targets can be identified at the same time. In addition, it cannot identify single products, only product categories.

On the contrary, the RFID tag has the advantages of small size, large capacity, long life, reusable, fast reading and writing, non-visual identification, mobile identification, multi-target identification, etc. Its ID code is unique in the world, so it becomes automatic An emerging force in the field of identification will become a leader in the field of automatic identification in the foreseeable near future.

Utilizing the uniqueness of RFID tags, sticking, embedding or implanting RFID tags on each piece of clothing can completely solve the problem of unidentified and tracking clothes when packing, and can also achieve precise packing.

1.2.3 Shorten the lead time

Shortening the supply cycle is one of the most important requirements of apparel companies. The requirements of apparel companies to shorten the supply cycle are as follows:

1. The supply cycle is shortened to about 2 weeks;

2. The production time for replenishment shall not exceed 7 days, and the logistics time shall not exceed 7 days;

Analysis: In order to shorten the supply cycle requirements, it is necessary to optimize the problems in production, packaging, inventory, and transportation at the same time. This solution mainly solves the problems that need to be faced in terms of packaging and inventory.

The most popular international practice is to use quick response QR technology, JIT timely production method, EOS electronic ordering system based on EDI technology and OPS order processing system to achieve the goal of shortening the supply cycle, and RFID label technology is to achieve the goal of shortening the supply cycle. Indispensable technical means for the cargo cycle.

1.2.4 Inventory Management

Inventory management is a very important part of the apparel industry, and the establishment of a quick response QR inventory management system is the key to rapid replenishment.

The inventory management of finished products of garment enterprises mainly includes finished product identification and positioning, packaging, stacking, warehousing, and inventory. After the finished product is offline, it is uniquely identified with an RFID tag, and information is collected on nodes such as packing, loading position and tray loading, so as to realize the effective and accurate positioning of the finished product in inventory management, and realize the real-time dynamic inventory of the finished product. Quick response to QR inventory management system to eliminate possible obstacles in inventory management.

Chapter 2 Solutions

2.1 Program overview

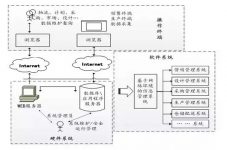

This solution is tailored for customers by INTI Technology (Huizhou) Co., Ltd. by analyzing the needs of the company. It integrates RFID technology, network technology, computer technology, database technology, voice technology and mobile communication technology. Combining the actual needs of Li Ning Group Co., Ltd. and the rich experience and unique technology of INTI Technology (Huizhou) Co., Ltd., we propose the following formal scheme of the RFID clothing picking and packing system.

Noun convention:

1. Clothing label: refers to the RFID label pasted on the clothing tag of a single product, with a unique unchangeable ID number, which can realize remote reading of information.

2. Box label: refers to the RFID label affixed to the designated position of the packing box, which is added by the labeler.

3. Pallet label: refers to the RFID label pasted on the pallet at the designated position, which is added by the labeler.

4. Position label: refers to the RFID label pasted on the designated position on the goods position, which is added by the labeler.

2.2 Technical indicators

The clothing picking and packing system based on RFID technology has the following technical indicators:

Ø Real-time monitoring of product categories and quantities in the picking and packing area;

Ø Real-time monitoring of the inventory location of each product in the inspection and packing area;

Ø Packing accuracy rate: 100%;

Ø Single product, box-level and pallet-level positioning accuracy: 100%;

Ø Support three packing modes:

l Direct packaging of products offline

l After the product goes offline, temporarily store the temporary storage space and then pack it

l Mixed operation of the above two methods

Ø Support packing first and then packing list;

Ø Support mixed packing of multi-size products;

Ø Support parallel packing of the same order by multiple people;

Ø Support parallel packing of multiple orders;

Ø Support real-time control of the status of off-line products in packing, temporary storage, pallets and other links;

Ø Support real-time dynamic automatic statistics and real-time online inventory;

[ad_2]