LIMS system solutions

[ad_1]

1. Project content

Summarizing the scope of application involved in this project, the content requirements are as follows:

1) Achieve comprehensive resource management in the grain purchase process, in accordance with the required entities, organizations, operators, instruments and equipment, test samples, method documents, environmental facilities, and entrusting parties.

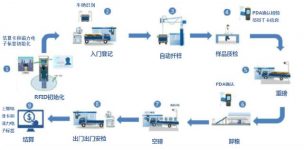

2) Realize the standardization and automatic management of the inspection process, and achieve full control during the circulation process.

3) Through the scanning of RFID tags and IC card information, the traceability of card issuing, vehicle verification, sample data, inspection data, inspectors, and grain receipt standards can be realized.

4) Realize the data collection and automatic upload of the results of the grain purchasing system and testing equipment.

5) Realize the report development function and query function, which is convenient for the leadership to query and export various forms of reports in a timely manner.

2. LIMS system solution

In accordance with the organizational structure required by ISO/IEC17025, it realizes all-round management of personnel, equipment, sample materials, specification documents, environmental testing, etc. The management scope includes organizational structure, personnel, inspection methods, inspection items, standards, testing equipment, and documents. Management, client management, equipment management, measuring instrument management, business partner management, reagent solution management (marking solution, common solution), material management (material procurement, material acquisition), inventory management, environmental temperature and humidity management, etc.

System security: user management, role management, authority management, audit trail and system log management, etc.

LIMS system

Inspection commission core business management: including the sample inspection of the company and other branches of the group and external commissioners. The core business functions of the LIMS system inspection include: business partner management, material management, warehouse/location management, inspection order management, price list management , Scanning code rule management, scanning code receiving management, QR code traceability management, client terminal management, container management, sample preparation management, equipment management, inspection time management, planned task management, HSE management, performance management, workflow management , Sample management, instrument data collection, result review, inspection report management, commission order inspection progress analysis, certificate management, etc.

Quality management: The LIMS system implements all laboratory quality control in accordance with the requirements of CNAS laboratory certification, including management review, internal audit, external audit, NCR non-conformance management, corrective and preventive measures, customer complaint management, etc.

Report and query statistics function: The system provides query statistics and report development functions, such as equipment pending inspection, personnel pending inspection, unfinished project, container report, inspection project progress query, inspection project qualification rate statistics, quality statistics (accumulated this year Compared with the same period last year, etc.) as well as quality weekly reports, monthly quality reports, statistics on unqualified samples, statistics on inspection timeliness, workload statistics, performance statistics and other functions.

Mobile platform: It has the same functions as the LIMS system, and realizes the synchronization update with the WEB terminal.

[ad_2]